cnc machine blueprints Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining .

Clean well water is essential for your home. Learn your options for removing rust and iron from your house's water supply in this thorough guide. If you’ve noticed reddish stains on your fixtures or a metallic taste in your drinking water, you’re likely dealing with iron contamination.

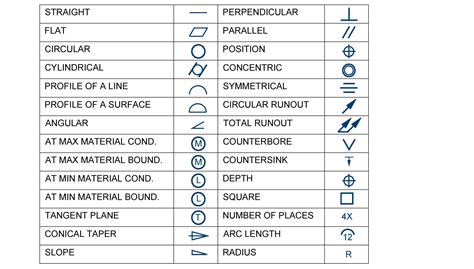

0 · mechanical symbols on blueprints

1 · mechanical blueprint symbols chart

2 · machinist blueprint symbols chart

3 · machine blueprint symbol chart

4 · blueprints for wrenches to machine

5 · blueprint symbol for gear reducer

6 · blueprint symbol chart

7 · basic blueprint symbols chart

The machine offers tool grinding at its best: Production and re-sharpening of rotationally symmetrical tools in the diameter range of 1 to 125 mm, with a maximum tool length of 235 mm and a tool weight up to 12 kg.

Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included.

Whether you're looking to build your own CNC machine or upgrade an existing one, having comprehensive and reliable plans is crucial. In this guide, we'll explore the world of CNC .Check out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in . CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and .Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining .

In the high-tech world of CNC machining, old-fashioned blueprints may seem a bit out of touch. Why bother learning how to read them when everything can be drawn up on the latest CAD and CAM programs?

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time .

Reading CNC blueprints requires a comprehensive understanding of various symbols, annotations, and technical specifications. These blueprints, also known as technical drawings or engineering drawings, contain crucial . To read blueprints for CNC machines, follow these steps: Start by understanding the blueprint’s symbols and abbreviations. Identify the part’s dimensions and tolerances. Look for special instructions like surface finish or . Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples.

Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included.Whether you're looking to build your own CNC machine or upgrade an existing one, having comprehensive and reliable plans is crucial. In this guide, we'll explore the world of CNC machine plans, and provide you with the tools and resources to .

Check out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in our guide. Includes all symbols per ASME Y14.5 and info on lesser-known legacy blueprint symbols.

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are .

In the high-tech world of CNC machining, old-fashioned blueprints may seem a bit out of touch. Why bother learning how to read them when everything can be drawn up on the latest CAD and CAM programs? Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.

Reading CNC blueprints requires a comprehensive understanding of various symbols, annotations, and technical specifications. These blueprints, also known as technical drawings or engineering drawings, contain crucial information for manufacturing parts using Computer Numerical Control (CNC) machines. To read blueprints for CNC machines, follow these steps: Start by understanding the blueprint’s symbols and abbreviations. Identify the part’s dimensions and tolerances. Look for special instructions like surface finish or heat treatment. Analyze the blueprint’s views and projections to visualize the part.

mechanical symbols on blueprints

Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included.Whether you're looking to build your own CNC machine or upgrade an existing one, having comprehensive and reliable plans is crucial. In this guide, we'll explore the world of CNC machine plans, and provide you with the tools and resources to .Check out our complete guide to GD&T symbols with tips to help you read and understand your manufacturing blueprints. Find out how to use datums and where they fit into your measurement. Learn how to work with basic dimensions in our guide. Includes all symbols per ASME Y14.5 and info on lesser-known legacy blueprint symbols.

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are . In the high-tech world of CNC machining, old-fashioned blueprints may seem a bit out of touch. Why bother learning how to read them when everything can be drawn up on the latest CAD and CAM programs? Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.

Reading CNC blueprints requires a comprehensive understanding of various symbols, annotations, and technical specifications. These blueprints, also known as technical drawings or engineering drawings, contain crucial information for manufacturing parts using Computer Numerical Control (CNC) machines.

brake for bending sheet metal

brackets metal brackets

Get the best deals on Dukes Of Hazzard Thermos In Collectible Metal .

cnc machine blueprints|blueprint symbol chart