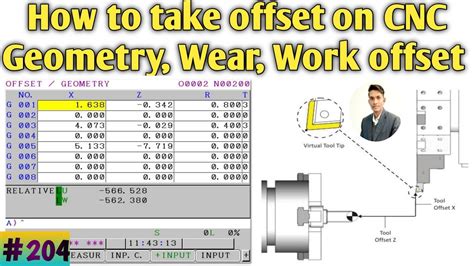

cnc machine offset Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. Sheet metal boxes are a versatile and essential component in various industries, ranging from automotive to electronics. This comprehensive guide will delve into the fundamentals of sheet metal boxes, their applications, and the intricacies involved in .

0 · what is wear offset

1 · what is tool offset

2 · what is tool length offset

3 · offset turning on lathe

4 · offset turning on cnc lathe

5 · geometry vs wear offsets

6 · fixture offset cnc

7 · cnc tool offsets explained

We were told when we set all the cable boxes and modem up that we need to specify a certain coax port in the house and to tell Spectrum if we wanted to move it. Well we asked if we could move it through their instant messaging support and they said we would need to have a tech come out and pay $50 to "activate the port."

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.The H CNC code tells the machine to which height (H) offset to use with the current .These work offset codes (G54-G59) are each matched to coordinate locations .Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise .

CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, .

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . The H CNC code tells the machine to which height (H) offset to use with the current cutting tool. The value of the H offset is the distance between the end of the spindle and the end of the cutting tool.

caledonian sheet metal

Because of how Machine Offsets add up, there are several ways CNC machinists can set their Tool and Work Offsets. This is especially true for Tool Length Offsets. Tool Offsets can be either Positive or Negative. Depending on your .

These work offset codes (G54-G59) are each matched to coordinate locations which have been set in the CNC machine’s offset library. Selecting a work offset code tells the CNC machine which work coordinate . Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in . Machining centers that have match offsets (also called coordinate system shifting) let the worker identify the location of the program zero point within offsets, keeping the assignment of program zero separate from the .

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate .CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best practices for offset management, machinists can achieve higher levels of .

The H CNC code tells the machine to which height (H) offset to use with the current cutting tool. The value of the H offset is the distance between the end of the spindle and the end of the cutting tool.Because of how Machine Offsets add up, there are several ways CNC machinists can set their Tool and Work Offsets. This is especially true for Tool Length Offsets. Tool Offsets can be either Positive or Negative. Depending on your Machine Shop .

These work offset codes (G54-G59) are each matched to coordinate locations which have been set in the CNC machine’s offset library. Selecting a work offset code tells the CNC machine which work coordinate system to use. The coordinate locations tell the machine where the zero location is. Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in manufacturing. Machining centers that have match offsets (also called coordinate system shifting) let the worker identify the location of the program zero point within offsets, keeping the assignment of program zero separate from the program. Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate .

calico metallic fabric

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best practices for offset management, machinists can achieve higher levels of .

The H CNC code tells the machine to which height (H) offset to use with the current cutting tool. The value of the H offset is the distance between the end of the spindle and the end of the cutting tool.

Because of how Machine Offsets add up, there are several ways CNC machinists can set their Tool and Work Offsets. This is especially true for Tool Length Offsets. Tool Offsets can be either Positive or Negative. Depending on your Machine Shop . These work offset codes (G54-G59) are each matched to coordinate locations which have been set in the CNC machine’s offset library. Selecting a work offset code tells the CNC machine which work coordinate system to use. The coordinate locations tell the machine where the zero location is. Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in manufacturing.

calculate bend radius of sheet metal

what is wear offset

25Pcs L Brackets for Shelves, 3 Sizes Angle Corner Braces Metal L Bracket Heavy Duty for Wood, Sturdy and Rustproof for Repairing Furniture with 82Pcs Screws Mounting Bracket Easily Black

cnc machine offset|cnc tool offsets explained