bending 16 gauge sheet metal Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro. Cost differences, ease of use/cutting, structural differences, building/fire code differences are all reasons why homes are built with wood while commercial buildings are typically built with metal. A home has a lot more framing than a typical commercial building which may be 4 walls and a cieling.

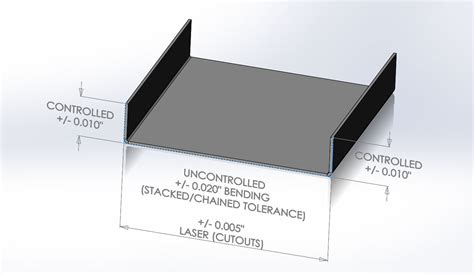

0 · sheet metal bending standards

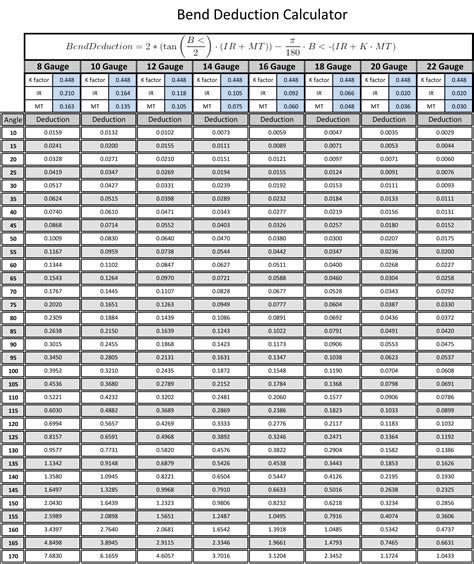

1 · sheet metal bending chart

2 · sheet metal bend allowance chart

3 · bending sheet metal by hand

4 · bending aluminum sheet without brake

5 · bend sheet metal without brake

6 · bend metal without a brake

7 · basics of metal bending

Can any one tell me what the 10 gallon milk cans in the40's and 50' were made of. Were they stainless or galvanized? I understand that cutting galvanized steel gives of Toxic fumes.

Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are .

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake.

your best bet, if you're determined to do it yourself, is to probably try rigging up some type of bending brake. perhaps clamping it to the edge of a workbench and using a .

Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake.

sheet metal bending standards

sheet metal bending chart

your best bet, if you're determined to do it yourself, is to probably try rigging up some type of bending brake. perhaps clamping it to the edge of a workbench and using a hammer to work it to a 90 degree bend. you're gonna have a .

Bending 16 gauge sheet metal requires the right tools, techniques, and safety measures to achieve accurate and clean bends. With the steps outlined in this article, you can bend sheet metal like a pro.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Here's a cool trick for bending thin-gauge sheet metal with. If you've got scrap sheet metal around, you can put it to use in projects to save material costs.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake.

sheet metal bend allowance chart

bending sheet metal by hand

Use the power of Alibaba.com, one of the largest B2B marketplaces in the world to find the right wholesale cnc turning spare parts for the materials and designs you are working with. These cnc machining shops can handle all requirements including milling, grinding, drilling, cutting and more.

bending 16 gauge sheet metal|bending sheet metal by hand