types of offset in cnc machine CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . Check out our wooden shelf with metal brackets selection for the very best in unique or custom, handmade pieces from our shelving shops.

0 · what is wear offset

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

Discover the incredible capabilities and specifications of the Schiess VMG6 PS, the world's largest CNC machine, revolutionizing manufacturing in aerospace, shipbuilding, heavy machinery, and energy sectors.

Types of CNC offsets. Each of the three offset types has a specific purpose. They each allow for flexibility when running your program. This includes allowing you to use the same program even if you need to change cutting .In this blog post, we will delve into the different types of CNC machine offsets commonly used in the industry. By understanding these offset types, operators, programmers, and enthusiasts .

This guide will focus on the common types of offsets used in CNC machining, such as tool length, diameter, wear, fixture, and workpiece offsets. Importance of Offsets in CNC Machining\. .

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . In CNC machining, tool length offset can occur due to wear and tear, replacement, or other factors. If not compensated for, the original tool path will not be executed accurately, .

CNC offsets allow the user to set specific work commands in the machine’s home position, alleviating the cumbersome process of repeated manual entry of coordinates. Geometry offsets, wear offsets, tool length . Do you know about the offsets in CNC Milling? Two types of offsets in CNC Milling and its differences explaining here.

what is wear offset

Dive into work holding and offsets on your Tormach CNC mill. We will guide you through vise setup, strap clamps, and more for secure machining.

Tool offsets are used on all turning centers to let the worker grip size with tools used in their programs. This permits the worker to regulate for flaws with tool settlement during setup. It also permits the worker to regulate . Results, vmc programming examples , cnc programming examples, admit card , new job vacancy , vmc programming, machine drawing, cnc , vmc ,cutting tool

CNC KNOWLEDGE is definitely the CNC Machinist Online Resources. You are warmly welcome to the world of CNC (Computer Numerical Control). CNC KNOWLEDGE provides free and detailed articles about cnc .

Types of CNC Machine Tool Offsets . 1. Tool Length Compensation (TLC):\ Tool Length Compensation is a type of offset used to adjust the Z-axis coordinates based on the length of the cutting tool being used. This ensures that the machine starts cutting at the correct depth, compensating for any variances in tool length. 2.

what is tool length offset

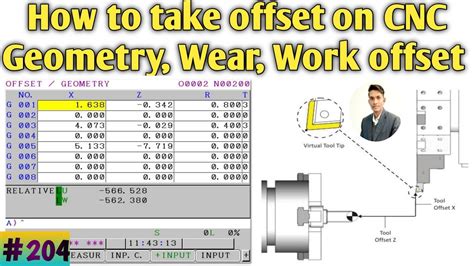

Hello Friends,In this video we will discus about offset of cnc machine . What is offset of cnc machine .Types of offset in cnc machine .How to take offset in.

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results. 1. CNC Milling Machine. CNC milling machines use rotating cutting tools to remove material from a workpiece. The primary 3-axis CNC machines move along an X-axis (side . offset of cnc machine in hindi | different types of offset of cnc | cnc offset setting hindi Support New channel https://youtube.com/@EKCNCStudyटेपर .

Types of offset in CNC Siemens Control. In this video I tell abouthow to open offset in CNC Siemens Control and how many types of Offset are in CNC Machine .Offset refers to the adjustment made to the machining program to compensate for slight variations in tool size, workpiece dimensions, and machine accuracy. In this blog post, we will delve deeper into the significance of offset in CNC machines, its types, and how it impacts the overall machining process. What is Offset in CNC Machining? Offset .

With most CNC machine tools, it is necessary to have at least one offset for each tool. Read more about your . offset. In the same manner, rotating centers have a feature named tool nose radius compensation. With this feature, an offset is used to identify the radius of the very tip of the turning or boring tool. . Type of Holders. BT Tool . दोस्तो जैसे की आप सब जानते है की cnc and vmc machine kya होती है, और केसे काम करती है जो लोग ये सब जानते है उनको यह भी पता होना चाहिए की offset kya होता है, tool offset kya होता है और work offset .

It is important to fully understand these two offset types since they provide a benefit that many CNC users overlook. Again, geometry offsets are used to assign program zero. By one means or another, the setup person determines the distances in X and Z from the tool tip at the zero return position to the program zero point. Types of offset in cnc vmc machine ||types of offset in cnc machine | cnc vmc programming#cncoffset#vmcoffset#cncprogramming#vmcprograming#typesofoffset#| H. All types of CNC machine tools require some form(s) of compensation. Though applied for different reasons on different machine types, all forms of compensation allow the CNC user to allow for unpredictable conditions related to tooling. . tool two will use offset two, and so on. Typically the tool nose radius (R column of the offset table . 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In .

offset turning on cnc lathe

It is one of the most common types of CNC machine, that have built-in tools for drilling and cutting. The materials are located inside a milling CNC machine, after which the computer will lead the tools to drill or cut them.. Most . Understanding the importance of CNC offsets can help manufacturers maintain consistency, accuracy, and efficiency in their production processes. Real-World Examples of CNC Offset Errors. To understand the .

How many types of offset are there in CNC machine॥ CNC machine me offset kitna hota hai॥ CNC ऑफसेट#sureshsaini #cnc #knowledgebaba#automobile #education Inst. What does the H CNC code do? The H CNC code tells the machine to which height (H) offset to use with the current cutting tool. . Both offset types allow more flexibility when running the program and when switching between various cutting tools. Both offset types are stored in the tool offset table. Tool offset table. CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing.They use different tools and methods depending on the material and the desired shape. CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy.They have a . If the operators are using any type of gaging with an RS-232 output capability they could use a system such as our EZ-Comp to automatically calculate a tool wear offset value based upon a statistical running average and transfer the value directly into the tool wear offset page. . I've made my living training shop people in the use of Fanuc .

There are several types of offsets commonly used in CNC machining. In this section, we will explore each offset type and how they affect tool positioning and workpiece accuracy. The primary offset types include: 1. Tool Length Offset . 2. Tool Diameter Offset . 3. Work Offset . 4. Wear Offset . Word Count: 75 . Section 3: Setting CNC Machine . All types of CNC machine tools require some form(s) of compensation. Though applied for different reasons on different machine types, all forms of compensation allow the CNC user to allow for unpredictable conditions related to tooling. . (R column of the offset table) and the tool type (the T column of the offset table) can be specified . 13. CNC Electric Discharge Machine An electric discharge CNC machine, also known as a spark CNC machine, is a special type of CNC machine that uses electrical sparks to manipulate materials into the desired shape. Electrical discharge has an erosive effect, meaning it can deform materials to which it’s exposed. Electric discharge CNC machines take advantage .Study with Quizlet and memorize flashcards containing terms like Which must be set first? a. Geometry Offset b. Work Offset c. Wear Offset d. Radius Offset, What does feed measure on a CNC Swiss-type lathe? Feed measures the: a. Distance the cutting tool travels before reaching the workpiece. b. Distance the cutting tool penetrates the workpiece. c. Rate at which the .

rock 94.5 full metal bracket

In this crude drawling when I touch off the 2" side of the 1-2-3 block the machine's Z reads -18.000" so in the offset page under the tool number I'm using, I hit tool offset measure button then with same tool selected go to command and type -2.000 enter or (+ -2.000) which allows for 2" block/standard that will set the table at -20.000 machine .ऑनलाइन क्लास लेने लेने के लिए इस लिंक को ओपन करे और डिटेल भरें https://forms.gle .

Made in the USA - Season 2 Episode 6: Why, and How, Hardinge is Reshoring Machine Tool Production In this episode of Made in the USA, several executives and senior staff at Hardinge give their first-person account of how they formulated the plan to shift the manufacturing of its milling and turning product lines from its Taiwan plant to its plant in Elmira, .

rlc-410 junction box

Stainless steel and exotic alloy fabrication for corrosive environments; Metallic and composite armor technology; Our passion to drive innovation inspires our team to deliver best-in-class solutions and exceptional service to a wide range of heavy industrial manufacturers.

types of offset in cnc machine|geometry vs wear offsets