what is feed in cnc machine Here is a breakdown of CNC feeds and speeds and a closer look at why feed rate optimization is so important to the success of your operation. Look at the company page for United Mechanical & Metal Fabricators, Inc. in Hayward , CA at DandB.com. Take advantage of the D&B Business Directory for business research.

0 · mechanica cnc feed chart

1 · diy cnc feeds

2 · cnc speeds and feeds

3 · cnc feed speed formula

4 · cnc feed rate examples

5 · cnc f feed rate

6 · cnc code for feedrate

7 · best cnc feed speed

Modern house numbers in 7 fonts with brushed aluminum, black, white, brass & bronze finishes in sizes from 4" to 15". Exterior custom address signs available.

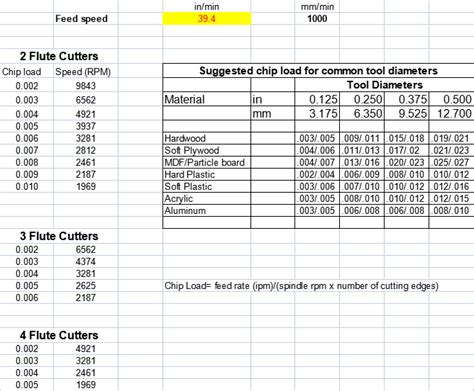

What are Speeds and Feeds in CNC Machining? Speeds and feeds refer to different velocities of a cutting process. While cutting speed determines surface feet of material removed per minute (SFM), spindle speed .This guide will help you get your feeds and speeds right on your CNC machine, with beginner and advanced chipload values. It will also deepen your understanding on this technical aspect of CNC milling. Table of Contents. What is the F code used for in CNC programming? The F code, or feedrate command, controls how fast the cutting tool moves. Feed rates set with the F code ."Feeds" refers to how fast the cutter moves through the material being machined. It's typically measured in inches per minute (IPM) or millimeters per minute (MMPM). The feed rate affects the quality of the cut, the finish of the surface, .

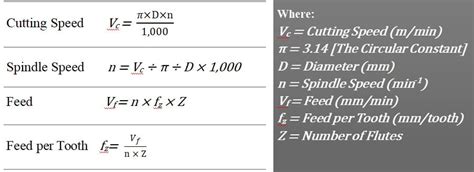

Here is a breakdown of CNC feeds and speeds and a closer look at why feed rate optimization is so important to the success of your operation.Feed refers to the rate of movement of the axes of your machine, it is programmed in inches per minute (IPM) or millimeters per minute for metric. Speed refers to the RPM of the machine spindle, i.e. the rotational speed of . Feeds and speeds refer to two separate velocities for machine tools: feed rate and cutting speed. Learn more about understanding feeds and speeds in CNC machining and how they can be optimized for improved . What is Feed Rate? Feed rate is the distance which the cutting tool during one spindle revolution. It is also defined as the velocity at which the cutter is advanced against the workpiece. It is measured in either inch per .

This guide explores an in-depth comparison of feed rate and cutting speed in CNC machines. Continue reading to learn their key differences and their critical roles in optimizing your CNC process to achieve optimal results!CNC Machines. CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom . Max Feed: The Maximum Feedrate the CNC machine is capable of while cutting. Appears on the Machine Profile and also on the Feeds and Speeds applet. G-Wizard will limit feeds to this value. Max Rapids: The Maximum Feedrate the CNC machine is capable of while moving the cutter. Normally the same as Max Feed, but some machines can move faster than .

Hello Dosto,Aaj Ke Is Video What Is Cnc Machine Cutting Speed, Feed, Spindle Speed Rpm And Depth Of Cut And How It Is Calculate In Hindi Ke Is Video Me Hum D. For example, a feed rate of 0.32945 mm/rev will be programmed as F0.329 and a feed rate of 0.08457 in/rev will be programmed as F0.0846 on most controls. Most CNC machines can work with both types of feed rate. CNC machining is a subtractive manufacturing process that involves shearing away material chips until the final product is achieved. So first, the machinists need to know the amount of material the machine will shear off in one revolution and the speed at which the CNC machine will move.

What is rapid feed rate? Rapid feed rate typically refers to the maximum feed rate achievable by the CNC machine. The rapid feed rate control on the machine will control the feed rate. The benefit of rapid feed is the speed of travel. Our manufacturing process can have shorter cycle times if we can get to the required destination in a shorter . CNC machining is a material reduction manufacturing process that involves cutting off material fragments until the final product is obtained. Therefore, first of all, the mechanic needs to know the amount of material that the machine will shear in one rotation and the movement speed of the CNC machine. By specifying the starting point, ending point, and feed rate, the CNC machine can accurately perform linear interpolation and create the desired slot on the workpiece. This is just one example of how linear interpolation can be applied in CNC machining, demonstrating its importance in achieving precise and efficient machining results. Maintain stable machine conditions: Ensure machine stability by adjusting feed and cutting parameters based on the CNC machine’s capability. Use recommended feeds and speeds : Always refer to tool manufacturer guidelines for ideal speeds and feeds for .

mechanica cnc feed chart

A coarse feed rate can be considered for the rough cut. For example, the feed rate can be considered as 0.01-0.05mm/rev for finishing operation and 0.1-0.3mm/rev for rough turning operation. Feed rate limit. The available machine tools have a feed-by-feed rod, within the minimum and maximum limit. What is stepover: Stepover is the distance your CNC machine moves your bit after each pass in the XY plane, measured as a percentage of the tool diameter.; How stepover affects surface finish: Smaller stepovers result in smoother surfaces and more details, but also longer machining time.Larger stepovers result in rougher surfaces and less details, but also faster . 2. The insert’s chip breaker geometry is designed to break chips within a particular range of chip thickness, and the chip thickness directly depends on the feed rate in mm/rev. Transform production and profits dramatically, in just a few months. With a CNC machine monitoring system. Etc. The Volkswagen Beetle The feed hold button on a CNC lathe is a crucial safety feature that allows the operator to pause or stop the movement of the axes during a program execution. This means that when the button is pressed, the machine will stop moving the axes and hold them in place until the button is released.

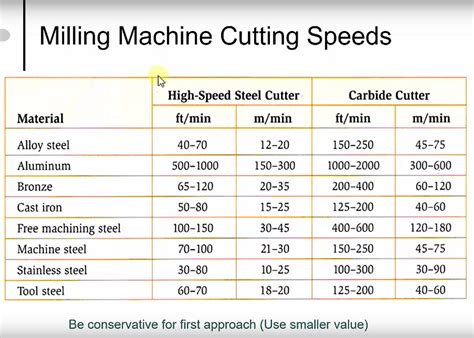

But to reach this level of efficiency, CNC operators must first have a clear understanding of each milling operation’s requirements, such as the CNC feed rate and cutting speed of each machine. Defining Important Terms. Manufacturers choose CNC machines because of their ability to automate production with extreme precision.

Importance Of Feed Rate In Cnc Machining Processes. The feed rate plays a crucial role in determining the machining time and the surface roughness of the finished area in CNC machining. It can be adjusted depending on factors such as the material being cut, the cutting tool material, and the desired tool life.

Chip load that is recommended for the cutter should come from the manufacturer of the cutter. You then divide down by feed rate and RPM. As far as lead in or out, depends on what you're cutting. I do a lot of acrylic. I ramp a spiral path inline with the cut at 4 degrees at the same feed rate as the cut pass.The surface finish and dimensional accuracy of CNC machined parts are influenced by the feed rate and spindle speed, as well as by other factors, such as the tool wear, the coolant, the clamping .

Permissible feed rate—Machine tools have a maximum and minimum limit of feed rate, beyond which, selection is not permitted. Again, conventional machine tools may have only few feed rate options within that range. Cutting tool geometry—Beside feed rate, tool geometry also affects surface quality. So, if geometry permits, then a higher value . Feed Rate Limit. Typical CNC machine tools possess a feed-by-feed rod within the minimum and maximum feed rate limits. Beyond the limit is impermissible for these machine tools, and only limited feed rate options within the permissible limit can be applied for conventional lathe machines. As such, maintain the permissible feed rate based on the .

The CNC machine uses different types of lathe tools. This tool can be made from soft or hard materials. The strength of the cutting tool contributes to optimum cutting speed. . Factors to be considered for Feed Rate in CNC Machining. Feed rate has fewer effects on the process, but it is essential for the perfect finishing of the workpiece. To .

CNC KNOWLEDGE is definitely the CNC Machinist Online Resources. You are warmly welcome to the world of CNC (Computer Numerical Control). CNC KNOWLEDGE provides free and detailed articles about cnc programming and machining etc. Easy to understand cnc programming examples are described with detail and images.CNC KNOWLEDGE is for .

For mid-range CNC machine tools, the feed speed is between 10-20 m/min and the resolution is 0.1 μm. For high-grade CNC machine tools, the feed speed is between 15-20 m/min and the resolution is 0.1 μm. In general, it is recommended that the resolution be at least one order of magnitude higher than the required machining accuracy of the .Now for one reason or other you want to increase or decrease the speed or feed of the cnc machine for some time, you definitely have a way to just alter the cnc machine program, but there is one more suitable solution the Feed Override and Speed Override Controls.The feed override and speed override are the most suitable and handy way to control the cnc machine feed and . The adjustment range of the spindle speed and feed rate of CNC machine tools is much larger than that of ordinary machine tools. The rigidity of the machine tool is high, allowing for large cutting quantities, thus effectively saving machining time. The rapid movement speed of the moving parts of the CNC machine tool shortens positioning and .

A line drawing showing some basic concepts of speeds and feeds in the context of lathe work. The angular velocity of the workpiece (rev/min) is called the "spindle speed" by machinists.Its tangential linear equivalent at the workpiece surface (m/min or sfm) is called the "cutting speed", "surface speed", or simply the "speed" by machinists.The "feeds" may be for the X-axis or the .What is CNC machining? By: CapableMaching Preface: Introduction Deep understanding and CNC machining First, let me explain what CNC is. The full name of CNC is Computer Numerical Control. CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process where pre-programmed computer software dictates the movement of machinery and .

The feed drive axis of a computer numerical control (CNC) machine tool is a composite mass system. This study modelized the feed drive axis of a machine tool into a two-mass model, and then used particle swarm optimization (PSO) to identify the physical parameters of the feed drive axis two-mass model for subsequent application. The modelization and identification method .

junction box enclosure hinge

diy cnc feeds

Two high-voltage openings (one for inlet power, one to daisy chain to other j-boxes), five low-voltage openings (one more than typical larger junction boxes to better accommodate nicheless lights) Includes built-in 100 W safety transformer

what is feed in cnc machine|cnc code for feedrate