oxy acetylen welding sheet metal vs mig welding Oxy-Acetylene Welding vs. Other Welding Process. The main difference between oxyfuel welding and arc welding techniques like SMAW, FCAW, GMAW and GTAW is the heat source. Oxyfuel welding uses a flame .

WALSH SHEET METAL in Scranton, reviews by real people. Yelp is a fun and easy way to find, recommend and talk about what’s great and not so great in Scranton and beyond.

0 · tig arc vs oxyacetylene

1 · arc vs mig vs oxyacetylene

New and Used WASINO - We have 12 listings for WASINO listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. .

tig arc vs oxyacetylene

Oxy-acetylene is a highly versatile and portable method, perfect for fieldwork, repair jobs, and smaller welding tasks. On the other hand, MIG welding excels in speed, ease of use, and high-quality, consistent welds, making it . Table of Contents. What is Sheet Metal Welding? Different Techniques of Welding Sheet Metal. MIG Welding. TIG Welding. Stick Welding. Plasma Arc Welding. Laser Beam .

8 port fiber distribution box

Re: mig vs oxy/acetylene for beginner If you attend welding school, the first thing you learn is to use a gas torch. You learn fusion welding, braze welding, heating and cutting . Oxy-acetylene welding depends on ignited oxygen and acetylene gas to produce flame that is capable of melting and fusing metals. Depending on the flame control, it is easy to change the heat and therefore use the . Fabrication of sheet metal: Thin to medium sheet metals are easily weld using gas welding. Aircraft industry: Oxy-Acetylene welding is commonly used in joining various aircraft parts.

Oxy-Acetylene Welding vs. Other Welding Process. The main difference between oxyfuel welding and arc welding techniques like SMAW, FCAW, GMAW and GTAW is the heat source. Oxyfuel welding uses a flame . Gas welding offers less penetration and heat than arc welding techniques, such as TIG and MIG welding. The process requires post-weld finishing to improve its aesthetic look. Oxyacetylene welding is prone to weld .

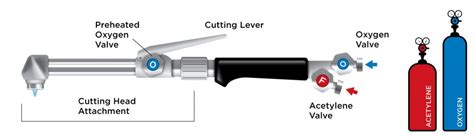

Oxy-acetylene gas welding, also known as gas welding, is a widely used welding process that makes use a flame produced by the combustion of a mixture of oxygen and acetylene gases to heat and melt the metal being welded. The . There are five types of gas welding which are categorized according to what gas is used (not all gas welding methods use the same type of gas). These are butane or propane, hydrogen, MAPP (methylacetylene .If I have nice new metal I'm welding, mig can make it look nicer and make painting simpler, especially if it's gas shielded. If I have to repair anything, or are working with used materials, I go for stick. 6010/6011 will easily burn through almost anything except heavy powder coating and leave you with a sound (if a little spattery) weld.

Hi I'm starting out doing repairs on thin sheet metal (1mm) and getting conflicting info re pressure. The table in my BOC welding guide suggests .14 BAR. Home MIG TIG Arc Paint Forum. Forums. New posts Search .If you have access to an oxy acetylene torch with welding tips, use that as your primer. There's a few different reasons I say this. . I started on oxy acetylene and moved up to stick, then mig, then tig. Really enjoyed stick. Tig is hard. . and stick and you're going to want to focus on thin sheet metal work, maybe even aluminum sheet and . For a successful metal fabrication, you must choose a suitable welding technique. In today’s guide, we are going to explore all fundamental facts about oxy-acetylene welding process. From equipment you need, welding process, welding position, flame and techniques, among other vital aspects. Therefore, before starting your next oxy-acetylene welding, read [.] Oxy-acetylene gas welding and MIG (Metal Inert Gas) welding are two popular welding methods, each with its own set of advantages, limitations, and ideal use.

Not surprisingly, as other forms of welding like MIG (metal inert gas) and TIG (tungsten inert gas) has grown in prominence, oxy welding has lost its industrial dominance. The need for faster welds using new types of metals has relegated the oxy-fuel process largely to niche fabrication work. The project outlined using a MIG welder, by doing what the author called button hole welds. . MIG, TIG, Stick, And Oxy/Fuel Welding; Ox-Acetylene Sheet Metal Welding; Welcome to Welding.com, the ultimate Source for Welding Information & Knowledge Sharing! . Victor 250 Oxy-Acetylene Rig (welding and cutting) Bobcat 773 F-350, 1999, 4x4 . One of the benefits of mig welding is that it produces a stronger joint than spot welding. Additionally, mig welding can be used to weld metals that are difficult to weld using other methods, such as aluminium. Difference Between Spot Welding and MIG Welding Cost. One factor to consider when choosing between spot welding and mig welding is cost. Keep a Steady Hand: Maintaining a consistent distance and speed will result in a smooth, even weld. For Stick Welding: Select the Right Electrode: The electrode you use should match your metal type and thickness. Each type (6010, 7018, etc.) has specific applications. Control the Arc Length: Keeping a short arc length minimizes spatter and helps achieve a .

I'm a novice welder looking for some advice on oxy-acetylene welding 18 gauge mild steel. My project involves try to weld a 4" ribbon of steel around a curved panel about 18" in diameter. . oxy-acetylene welding sheet metal? hello. I'm new to this forum. I'm a novice welder looking for some . 1 Lincoln MIG PAK 15 1 Oxy-Acet. Reply . 03-27 .Flanges on pipes are best to be friction-welded. Very different materials are best joint by soldering or brazing instead of welding, depending on the materials. TIG and oxy-acetylene are basically interchangeable, oxy-acetylene is the older method and better suited for off-grid applications than electrical methods. Exploring MIG Welding. MIG welding, which stands for Metal Inert Gas welding, is a widely used and versatile welding process. . MIG welding, with its clean and precise welds, is the go-to choice for automotive and thin sheet metal projects. But remember, there’s no one-size-fits-all answer in the welding world. . stick welding, and oxy .

Gents I am looking to get an oxy / acetylene setup for heat shrinking automotive sheet metal. I have shrinking discs which I love but the noise is causing issues with the neighbours. Excuse my ignorance but do I just need a standard oxygen / acetlyene setup kit (and the oxygen / acetlyene. Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs . Different Techniques of Welding Sheet Metal MIG Welding; TIG Welding; Stick Welding; Plasma Arc Welding; Laser Beam Welding; Gas Welding; . gasoline, oxy-acetylene, or oxygen. The method employs . MIG welding is a form of arc welding that uses an electric arc between a consumable metal wire electrode and the metal workpiece. The wire is fed through a gun-like device called a torch, which helps guide the arc with an . Welding processes like TIG welding, MIG welding and others are used. However, among them Oxy-Acetylene welding is a flexible and widely used process to fuse the metals. The process of Oxy-Acetylene welding forms a flame which melts the metal for cutting and joining, by combining two gasses, namely acetylene and oxygen.

But I do hear 3/16" is called plate a lot more than I hear it called sheet metal. To me sheet metal is something that can be cut with tin snips or electric cutting shear or nibbler. It's like calling a person who welds a welder vs weldor. I've done a .From time to time, we’ll hear these whispers of an ongoing war: Plasma Cutters Vs. Oxy Acetylene, the great debate, the civil war among welders. It’s like there’s gangs of welders roving around with “Plasma Cutter” written on their leather jackets or “Oxy Acetylene” tattooed across their chest. So, let’s settle this ri The process has high-quality welds with clean finishes compared to other welding processes, such as oxy-acetylene or shielded metal arc welding (SMAW). It’s also capable of producing welds in tight spaces. It can be used on thinner materials than other processes, such as oxy-acetylene or SMAW, because it does not require as much heat input . My welding class at school is split into Oxy-Acetylene and Stick (SMAW) Welding groups. And it is natural that we have quite a rivalry going on between the two. . Shielded Metal Arc Welding (Stick Welding) 66.67%. 22 votes. Last edited by Horatio; 09-28-2004, 02:05 AM. . but I also think there should be a progression from O-A to stick to .

Gas Metal Arc Welding: A Closer Look. Gas metal arc welding (GMAW), also known as MIG welding, is a popular and versatile arc welding technique that uses a consumable wire electrode continuously fed through a welding gun. GMAW relies on an inert shielding gas, such as argon or carbon dioxide, to protect the weld pool from contaminants.I find it to be a bitch for auto body work. .023 wire MIG with 75/25 gas is great for sheet metal work. Thicker than about 14ga I move to .035 wire. . followed by oxy-acetylene, then stick and finally MIG. Once you have all your merit badges you can try TIG. . I'm going to pretend OP is mig welding and too lazy to replace the empty bottle .

Propane is safer than acetylene. Acetylene will start to decay to hydrogen and carbon if shocked. So if you just need to demolition cut in difficult places then propane is the safe choice. The bottle sizes of oxy-acetylene are like 1 oxygen to 3/5 acetylene because you really don't need lot of acetylene, just to heat up the part and keep the flame. MIG vs. TIG Welding: Key Differences. MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular welding methods, each with distinct advantages: Weld Speed: MIG welding is faster, ideal for production settings, due to its automatic wire feed and broader arc. TIG welding is slower, requiring manual filler rod feeding and .

MIG (Metal Inert Gas) Welding. . Oxy-acetylene welding was developed in 1903 by French engineers Edmond Fouché and Charles . aluminum, and cast iron. Particularly good for thin sheet materials. Flame Temperature: Oxy-acetylene welding can reach temperatures of about 3,200°C. Weld Depth and Precision: Typically used for materials under 6mm .Intro to Oxy-Acetylene Welding - Part 1Video for my high school students to follow as they learn the process of using the Oxy-Acetylene torch. Yes I know the.This is the root of all welding performance. As a gas (oxy-acetylene) welder first, it was MUCH easier to learn to TIG later. BTW, excellent first attempt, keep up the good work! . If you're feeling lazy I may or may not know that you can plasma intentionally burn .

arc vs mig vs oxyacetylene

8 foot sheet metal brake for sale

Wardrobe Clothing Moving Boxes with Metal Hanging Bar, 24 x 24 x 40 Inches, 3 Pack

oxy acetylen welding sheet metal vs mig welding|arc vs mig vs oxyacetylene