junction and pull box sizing You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . I've made videos in the past about welding 22 or 24 gauge steel with gas-less flux core wire, I thought I'd give it one more shot here after being a little m.

0 · sizing electrical junction boxes

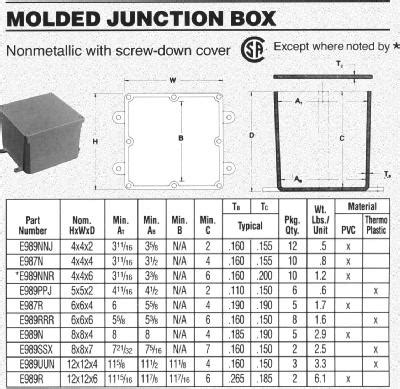

1 · pvc junction box size chart

2 · nec junction box size chart

3 · nec box sizing chart

4 · junction box sizing calculator

5 · junction box sizes chart

6 · junction box size in mm

7 · calculating junction box size nec

Unlike static PDF Study Guide for Jeffus/Burris' Welding and Metal Fabrication solution manuals or printed answer keys, our experts show you how to solve each problem step-by-step. No need to wait for office hours or assignments to be graded to find out where you took a wrong turn.

Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger.You must size pull boxes, junction boxes, and conduit bodies large enough so a .Pull boxes, junction boxes, and conduit bodies must be sized to allow . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For .

Sizing rules. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size .This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According .

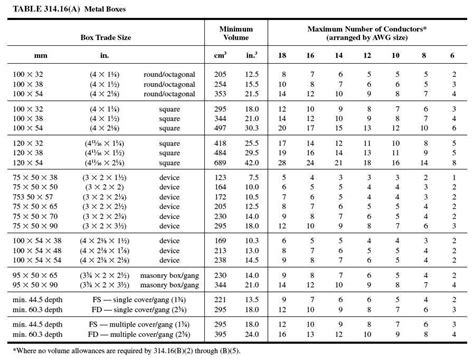

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in . Pull boxes, junction boxes, and conduit bodies must be sized to allow conductors 4 AWG and larger to be installed without damage to the conductor insulation. The NEC provides sizing requirements in Sec. 314.28.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to .The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat .Calculations are different for pull and junction boxes. Boxes containing conductors of 4 AWG or larger, under 600V, are calculated from the sizes and numbers of raceways (see Figure 1). Where pull and junction boxes are used on systems .

The specific size of the pull box depends on the size and the number of conductors. In addition, the diameter and the quantity of the raceway also determined the size of the pull box. Junction boxes and pull boxes used . Re: Pull and Junction Box Sizing The Box Dimesionning is what you have to consider, allowing at all time the space for the bending radius of the conductor, The rule says that for straight pull Box Size should be At least 8 Times the Conduit Size, for Perpendicular Pull The Diagonal Dimension fron Conduit Center To Conduit Center is 6.5 Times Conduit Size, The .When calculating the size pull or junction box for different size conductors rated 6 AWG or smaller, the cubic inch rating of each conductor from Table 370.16(B) must be selected and multiplied by the number of conductors based on each cubic inch rating. This total cubic inch rating is then used to size the box.

Welcome to the YouTube channel that supports your business with knowledge and tips on electrical, fire, and life safety.With instant digital access to codes .CEC 12-3036 Pull box & Junction box size cheat sheet . Does anybody have a visual diagram of this rule or any sort of cheat sheet? I feel like I saw one before. Share Add a Comment. . Follow the 8's for your straight conduit size multiplier and the 6 for any other routing other than straight through. Reply reply Top 1% Rank by size .

Select Box Type: Choose the type of junction box you are using (e.g., plastic, metal). Calculate Box Size: Click “Calculate” to determine the required size of the junction box based on the entered information. How Do I Size a Pull Box? To size a pull box:

Quick Tips for Pull Box Sizing. Tips for learning: Pull box calculations become easier with more practice. Use practical field examples to practice calculations. Draw up some sample pull boxes and calculate them. Obtain drawings from a completed project and “reverse engineer” the box sizes by calculating them. Junction Box Sizing. Sizing junction boxes follows standardized guidelines from NEC 314.16. This section breaks down the straightforward process for conductors ranging from 18 AWG to 6 AWG, eliminating guesswork and complex calculations. Base Requirements: Volume depends on the wire count; Box fill calculations are not needed I want to use a 24" long box so it's long enough to straddle past the center knockouts on two panels on 16" centers. I'm thinking a 24" x 12" x 6" box will do, but the NEC sizing seems to indicate a 24" x 18" x 6" box is necessary. This will hall under the angle-pull rules.

sizing electrical junction boxes

Video covering general requirements for pull and junction boxes as well as how to size them.

Describe requirements for sizing pull and junction boxes. Explain how properly placed pull boxes make it easier to pull conductors.Watch the full video at:ht. Do I have to size my splice/junction box based on conduits alone? Is there an exception somewhere that allows me to transfer box size to cu.in. And go with that instead? I have to get a min 41.5x41.5 304 stainless steel box and there’s nothing readily available in so cal so I’m looking at a minimum 3-5 weeks to have it fabbed. Do I have to size my splice/junction box based on conduits alone? Is there an exception somewhere that allows me to transfer box size to cu.in. And go with that instead? I have to get a min 41.5x41.5 304 stainless steel box and there’s nothing readily available in so cal so I’m looking at a minimum 3-5 weeks to have it fabbed.

NCCER Electrical Level 2 Module 5 "Pull and Junction boxes" 29 terms. jordan_leblanc75. Preview. Lv.2 Ch.5 Test. 40 terms. Austin_Seiter8. Preview. CIS 110 MODULE 1. 54 terms. Alicia_Peruso. . when sizing pull and Junction boxes for systems over 1000v you need to know. About us. About Quizlet; How Quizlet works; Careers; Advertise with us .

314.28 Pull and Junction Boxes and Conduit Bodies. Boxes and conduit conduit bodies used as pull or junction boxes shall comply with 314.28 (A) through (E). . This is significant, and can very negatively impact you if you get called on box size if you are not aware or fail to understand this code section. 8 times the conduit size is a lot . Do I need to size a pull box on the exterior of the building that is for fiber optic cable per 314? What I have is a 4" conduit coming out of the ground and entering a pull box on the exterior of the building. From there we are downsizing the conduit to 2" inside the building. Do I need a 24x24 can because of the 4" conduit? Can I use an 4" LB? About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Boxes and conduit bodies enclosing conductors larger than 6 AWG (under 600V) must also comply with the provisions of 314.28. These boxes are calculated from the sizes and numbers of conduits or raceways. Last month’s Code in Focus started a discussion of pull- and junction-box sizing requirements. This month, the discussion continues with .

This video shows how to size a Pull Box for and angle pull. Another interpretation of Art. 314.28.The Rule is to take the largest Conduit and multiply it by . For conductors smaller than #4 a junction/pull box is sized per 314.16 based on a volume calculation. Chris

Article 314.28 A ( Minimum size Pull and Junction boxes and conduit bodies)states that if the conductor is #4 or larger, the following box calculation will be used and so forth. Ive been arguing this fact for months with other electricians and designers that say if the Belden cable diameter is equal to #4, you have to use this article.

It's been a while and I forgot. How do I size a junction box. Not for pulls, but for conductor fill of 4awg and larger. I'm basically going to be splicing two 4-3 ser cables and will do it in a 6" box but I'd like to know the correct calculation again. Box cubed. Table 5 . Subject - Junction Box Sizing . June 30, 2008 This newsletter was sent to 28772 newsletter subscribers. . The sizing requirements for pull boxes, junction boxes, handhole enclosures and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger. .

pvc junction box size chart

Article 3.14 - Outlet, Device, Pull, And Junction Boxes; Conduit Bodies; Fittings; And Handhole Enclosures. DISCLAIMER. This is not an official copy of the Philippine Electrical Code. This is a Design Guide according to the provisions of the Philippine Electrical Code. It also provides interpretation and annotations of the clauses of the .

I have an installation where (3) 4" EMT conduits will be entering a pullbox from the bottom, and exiting out the back (at the top) Assuming that I'm correct that since the conductors don't exit directly across from each other, the calculation would be .For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide further overview of the sizing rules for the most common types of pulls, along with a calculation example. Straight Pulls | Pull Box. In straight pulls, conduit enters and leaves on opposite sides of the box.if the largest trade diameter of a raceway entering a pull box is 3", and it is a straight pull, the minimum size box allowed is _____ 24" factors to consider when installing boxes are covered in. NEC sections 314.15 through 314.30. all boxes must be sized, installed, and supported to meet the current _____ requirements . junction box. each .

MIG and TIG welding of galvanized steel to mild steel is carried out using ER70S-6 or ER70S-2 type filler wire. Preheating is usually not needed for galvanized steel due to sheet metals that have low thickness only.

junction and pull box sizing|junction box sizing calculator