5s cnc machine This is a 5s training video for our cnc machine shop. $20.99

0 · making 5s a machine shop

1 · how to make 5s work

2 · how to implement 5s

3 · 5s in manufacturing workplace

4 · 5s in manufacturing process

5 · 5s in manufacturing industry

6 · 5s in machine shop

Metal boxes are a good choice for high-current applications, while plastic boxes are more suitable for corrosive or damp environments. Plastic electrical boxes are the most common type of electrical box. They are made from a variety of .

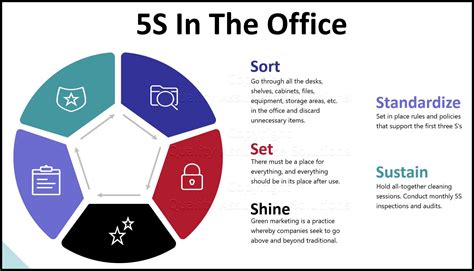

This is a 5s training video for our cnc machine shop.The 5S methodology offers significant benefits for streamlining CNC machine operations. By utilizing the principles of Sort, Set in Order, Shine, Standardize, and Sustain, manufacturers . The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving cleanliness, safety, and efficiency. This blog will explore .Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in .

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move. Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy.Learn why your shop should embrace 5S in the workplace, and how to do it. A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn can lead to a rosier bottom line.This is a 5s training video for our cnc machine shop.

The 5S is a methodology aimed at optimizing the productivity and reducing waste at the factory. It makes use of visual cues and an orderly workplace to achieve consistent results. The 5S is implemented by small teams working together to achieve a higher goal of efficiency.The 5S methodology offers significant benefits for streamlining CNC machine operations. By utilizing the principles of Sort, Set in Order, Shine, Standardize, and Sustain, manufacturers can achieve enhanced productivity, improved quality, and a safer working environment. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving cleanliness, safety, and efficiency. This blog will explore each step of 5S management and its benefits for a CNC machining environment.Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in your shop today. Tips to introduce this useful practice into your shop.

making 5s a machine shop

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy.Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts.

The 5S methodology is simply a systematic laid out plan to visually manage the entire manufacturing unit. The term 5S stands for five terms, all of which start with the letter ‘S’. The original Japanese terms are: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke.Learn why your shop should embrace 5S in the workplace, and how to do it. A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn can lead to a rosier bottom line.This is a 5s training video for our cnc machine shop. The 5S is a methodology aimed at optimizing the productivity and reducing waste at the factory. It makes use of visual cues and an orderly workplace to achieve consistent results. The 5S is implemented by small teams working together to achieve a higher goal of efficiency.

how to make 5s work

The 5S methodology offers significant benefits for streamlining CNC machine operations. By utilizing the principles of Sort, Set in Order, Shine, Standardize, and Sustain, manufacturers can achieve enhanced productivity, improved quality, and a safer working environment.

The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving cleanliness, safety, and efficiency. This blog will explore each step of 5S management and its benefits for a CNC machining environment.Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in your shop today. Tips to introduce this useful practice into your shop.

atech metal fabricators

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move. Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy.

Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts.

how to implement 5s

5s in manufacturing workplace

5s in manufacturing process

5s in manufacturing industry

Metal boxes must be used with metallic cables or conduit. Answers based on the National Electrical Code. Local amendments may apply. Check with your local building officials. Remember Junction boxes have to be accessible. Under the insulation is not acceptable. Metal boxes are better when you need the strength and volume to make up a ton of wires.

5s cnc machine|5s in manufacturing process