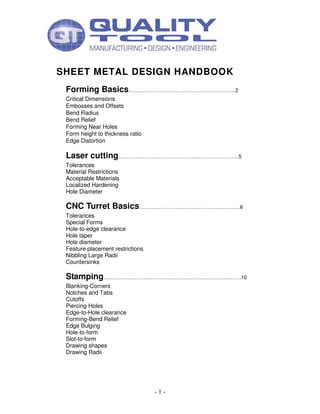

rules for laser cutting sheet metal The process of laser cutting sheet metal involves three main steps: preparing the sheet metal, setting up the laser cutter, and executing the cutting process. Here’s a brief overview of each step. Preparing the Sheet Metal Instrument junction boxes are used in many systems, and they would be used in different kinds of work locations like wet or dry conditions. These boxes can also be seen in safe and hazardous areas too.

0 · sheet metal placement restrictions

1 · sheet metal installation restrictions

2 · sheet metal distance calculator

3 · sheet metal cutting restrictions

4 · material restrictions sheet metal

5 · laser cutting systems

6 · laser cutter design

There are several different methods and approaches to sheet metal welding, and each method has its own uses in different circumstances. Our first goal is to provide information about different welding methods in the list below.

The process of laser cutting sheet metal involves three main steps: preparing the sheet metal, setting up the laser cutter, and executing the cutting process. Here’s a brief overview of each step. Preparing the Sheet Metal Laser cutting is a precise and versatile method used for cutting sheet metal. The maximum thickness that can be cut depends on several factors, including the type of metal, the laser’s power, and the quality of the cut required. What is Laser Cutting Sheet Metal? Laser cutting sheet metal is a subtractive manufacturing process used to precisely cut and shape sophisticated metal parts. This innovative technique allows manufacturers to employ various . Such automation forces proactive decision-making in the laser department and changes the rules of the laser game in a fundamental way. A new objective is now present and of utmost priority: optimization for part removal, whether automated or manual. This often will overshadow those three KPIs traditionally used in laser cutting.

Besides the CO 2 laser in the FMS, which is designed for sheet metal 10 gauge and thinner, the operation replaced its last stand-alone CO 2 laser late last year—with an 8-kW TRUMPF solid-state laser, no less, complete with part loading/unloading automation that incorporates a parts-offloading conveyor.Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles.In 3D programs, sheet metal rules will include the information needed for the program to automatically calculate the correct formed versus flat dimensions for a part. Programs will have default rules and they may not match the properties for the actual material you will be using, or a fabricator’s process. . 5052 Aluminum Laser Cutting .I'm interested in cutting small simple shapes from aluminum thin sheet metal. I plan to cut perimeter shapes and score lines to allow bending the pieces into simple open box / consolet type enclosures. . A fiber laser to cut aluminum sheet is going to cost -40K on the low end., Use 3 Phase power and weigh several thousand pounds. If your .

The fiber laser has made the primary cutting operation at most metal fabricators extraordinarily productive—until a part tips and causes a head to stop or crash. To prevent this starts with knowing some nesting fundamentals and, most critically, how decisions in nesting and laser programming affect all the manufacturing steps that follow.Get the most out of a fabricated metal project by understanding design rules and bending constraints. . How It Works. Services. Laser Metal Cutting. Laser Tube Cutting. Flat Finishing. Bending. Metal Tapping. Powder Coating. On-Demand Fabrication. Resources. Capabilities. . Sheet Metal Bending Guidelines. CONTACT. OSH Cut, Inc. 3052 North .Our paramount objective is to ensure utmost satisfaction in your supply chain by fulfilling your sheet metal requirements. Every facet of our sheet metal laser cutting services is meticulously crafted to furnish you with the exact, pristine, and precise components precisely when you need them. jlfmetalworks.comHigh Quality Sheet metal laser cutting machineLaser power: 12000W Working area: 6000*2000mm (customizable)Official site: www.xianminglaser.com/Liaocheng .

Hi, I use a 12"x12" piece of 16 gauage sheet metal (ungalvanized) centered of my layout board. About at Home Depot. Other than occasional engraving on woodworking projects, most of what I do is on 3mm ply and smaller than 12x12.OSH Cut is revolutionizing precision sheet metal and plate manufacturing. We offer instant online prices and rapid lead-times for precision sheet metal parts, including metal laser cutting, tapping, deburring and graining, metal bending, and powder coating. We can make your custom sheet metal parts as fast as same-day. The first is in the initial Sheet-Metal feature that is created when your part is made using the sheet metal tools (or converted to sheet metal). From here you can select to have relief added automatically on bends that require it. . All holes and cutouts are at least 50% material thickness for laser cut parts; All holes and cutouts are no .

CNC machining: Mechanical CNC machines can also cut sheet metal. These machines use a rotating cutting tool or a hard metal blade to cut through the workpiece. Waterjet vs laser vs plasma cutting. Sheet Metal Forming. Sheet .

sheet metal placement restrictions

This guide details the necessary PPE for laser cutting operations and how to use it effectively. 1. Laser Safety Glasses: Always wear appropriate laser safety glasses that match the laser’s wavelength to protect your eyes . When designing or working with sheet metal, certain rules govern the creation of holes to ensure structural integrity, manufacturability, and ease of production. Here are the general rules for sheet metal holes: 1. Minimum Hole Diameter The minimum diameter for holes should typically be equal to or greater than the thickness of the sheet metal. [.] The fiber laser changed the laser cutting game, not just for its speed but for its wavelength. The CO 2 laser beam’s 10.6-micron wavelength had decades of success since the birth of the laser cutting industry, but when it came to nonferrous material, optical reflectivity reared its ugly head. This complicated laser cutting nonferrous material in a big way.

This article presents valuable design tips for laser-cut parts, aiming to enhance your knowledge and improve the outcome of your laser cutting projects. Overview of CNC Laser Cutting CNC laser cutting is a subtractive manufacturing technology that utilizes a high-power laser beam to cut flat-sheet materials.What's the most efficient way to countersink laser cut sheet metal for mid-volume production? I have around 10 different aluminum parts that need 4 to 10 M3 countersinks each for a production run of 1000. Using a CNC seems really inefficient so I'm wondering what's the industry standard way of doing this. Laser cut sheet metal is a popular material in many industries due to its durability, strength, and versatility. At SendCutSend, we stock multiple high-quality materials and offer CNC bending services so your project is limited only by imagination (and a few pesky rules of physics). In this guide, we’ll discuss ways to accommodate those rules so you can avoid deformation in .We have guidance on updating sheet metal rules in Fusion 360 and SolidWorks. . Upload your CAD design, or try one of our customizable part templates to get instant pricing on your custom laser cut parts. All delivered to your door in a matter of days. Upload a CAD file. We accept .ai, .dxf, .dwg, .eps, .stp, and .step.

Welcome to India’s Instant Quotation online Laser Cutting Service by Robu.!! We believe in the ideas of our makers, and hence moving ahead with our tagline “YOUR IDEAS-OUR PARTS” we have added Laser Cutting at our service line-up to support your ideas at an economical price. Initially, we’ve set up a laser cutting service for most popular materials like Mild Steel, . This has several consequences in the design rules for metal laser cutting: 1. Your details can’t be smaller than the metal sheet’s thickness. For metal laser cutting, because of this initiation, you can’t include in your design details that are smaller than the material’s thickness. It goes for holes (their diameter needs to be bigger . The comparison of laser cutting, oxyacetylene cutting and plasma cutting methods is shown in Table 1. The cutting material is 6.2mm thick low carbon steel plate. Rapid Sheet Metal | Prototype Sheet Metal | Sheet Metal Parts (2) High cutting efficiency. Due to the transmission characteristics of laser, the laser cutting machine is generally . Sheet Metal Cutting: Laser cutters are widely used to cut both sheets and plates in a wide variety of materials including metals, plastics, and wood. Engraving: Laser cutters can be used to mark almost any material. Lasers can be used to add serial numbers to manufactured parts or for more artistic applications like wood marking.

So I've installed a 'stencil font', create a sketch on the surface I want laser cut letters in my sheet metal, then exit the sketch but the cut command says there is an error, no valid closed loops suitable in sketch. Any suggestions, do I need to explode the text? I have no issues doing this in solid objects, just sheetmetal issue. p.s.

sheet metal installation restrictions

sheet metal distance calculator

sheet metal cutting restrictions

Sheet metal air ducts are the most durable type of air duct construction, and because of their non-porous surface, are the least likely to have mold or biological growth. Some sheet metal air ducts are lined with an external or internal fiberglass duct liner.

rules for laser cutting sheet metal|material restrictions sheet metal