data m sheet metal solutions Range of Application. Roll forming is a proven, highly efficient and energy . The size used should equate to the current rating of the circuit being connected into - you can always use a higher rated box than the circuit but never a lower rated box. For a lighting circuit use a 20amp junction box and for a ring main or radial circuit use a 30 amp junction box.

0 · data m sheet metal products

1 · data m roll forming solutions

Is it permissible to use a box such as a Raco 192 (4" sq) box under an outside canopy ? The NEC notes that such areas are deemed "lamp locations" in definitions. 314.15 simply states in damp and wet locations boxes should be .

data m sheet metal products

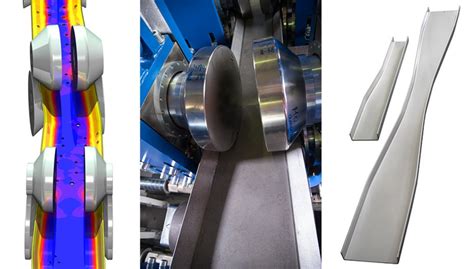

data M Sheet Metal Solutions GmbH specializes in software development and engineering services in the sheet metal processing industry. Our software and hardware .At EuroBlech 2024, data M will be exhibiting for the first time at the EFB joint stand .Range of Application. Roll forming is a proven, highly efficient and energy .COPRA RF and COPRA FEA RF digitized the design process and thus .

data M Sheet Metal Solutions GmbH is a company specialised in the field of sheet .In case you contact our company by email or via this contact form, we store the .

oem collins metal fabrications

Two steps are necessary for the measurement of the profile surface. .The COPRA RollScanner generates an accurate set of data of a roll's true .Here you can find an overview of our products and services: data M Sheet Metal Solutions offers its customers a variety of software and hardware solutions as well as services in the field of roll forming.data M Sheet Metal Solutions GmbH is a company specialised in the field of sheet metal processing. We have been developing and distributing the worlds leading software solutions .

data M Sheet Metal Solutions GmbH specializes in software development and engineering services in the sheet metal processing industry. Our software and hardware solutions for roll forming are market leaders - worldwide.data M Sheet Metal Solutions offers its customers a variety of software and hardware solutions as well as services in the field of roll forming. The programs COPRA RF and COPRA FEA RF for design, simulation and analysis are market leaders worldwide and form the basis for our COPRA Roll Forming workflow.

data M Sheet Metal Solutions GmbH is a company specialised in the field of sheet metal processing. We have been developing and distributing the worlds leading software solutions for roll forming COPRA RF, COPRA FEA RF and metal bending COPRA MetalBender.Find all data M Locations. data M Sheet Metal Solutions GmbH Am Marschallfeld 17 83626 Valley, Germany +49 8024 640 0 www.datam.deRoll forming is a proven, highly efficient and energy-saving technology for the production of profiles with complex cross section geometries out of sheet metal with thicknesses from fractions of a millimetre up to 16 mm - in some cases even higher.Two steps are necessary for the measurement of the profile surface. First, it needs to be digitalized, so the data can be processed afterwards. Usually, optical devices are equipped with a sensor ring consisting of a variety of cameras.

COPRA RF Roll Design offers in its roll editor a variety of features for an effective roll tool design. Once the roll design is finished, the data often has to be processed rapidly so as to avoid time losses. The COPRA® RF process chain also.

The COPRA RollScanner generates an accurate set of data of a roll's true shape. Scanned rolls can be compared immediately to the originally designed contour. This means no more "fire-fightings" due to unexpected and unnecessary long try-outs.

Valley, 17.09.2024 The Bavarian company data M Sheet Metal Solutions GmbH is presenting the new version of COPRA RF with numerous innovations at EuroBLECH 2024. Highlights of Version 2025 include significant improvements to the Deformation Technology Module (DTM) and integration with Bricsys NV’s BricsCAD as an additional CAD system alongside .In case you contact our company by email or via this contact form, we store the data you provide in order to answer your enquiry. You can read more about data processing at data M in our privacy policy. data M Sheet Metal Solutions GmbH specializes in software development and engineering services in the sheet metal processing industry. Our software and hardware solutions for roll forming are market leaders - worldwide.

data m roll forming solutions

data M Sheet Metal Solutions offers its customers a variety of software and hardware solutions as well as services in the field of roll forming. The programs COPRA RF and COPRA FEA RF for design, simulation and analysis are market leaders worldwide and form the basis for our COPRA Roll Forming workflow.data M Sheet Metal Solutions GmbH is a company specialised in the field of sheet metal processing. We have been developing and distributing the worlds leading software solutions for roll forming COPRA RF, COPRA FEA RF and metal bending COPRA MetalBender.

Find all data M Locations. data M Sheet Metal Solutions GmbH Am Marschallfeld 17 83626 Valley, Germany +49 8024 640 0 www.datam.deRoll forming is a proven, highly efficient and energy-saving technology for the production of profiles with complex cross section geometries out of sheet metal with thicknesses from fractions of a millimetre up to 16 mm - in some cases even higher.Two steps are necessary for the measurement of the profile surface. First, it needs to be digitalized, so the data can be processed afterwards. Usually, optical devices are equipped with a sensor ring consisting of a variety of cameras.COPRA RF Roll Design offers in its roll editor a variety of features for an effective roll tool design. Once the roll design is finished, the data often has to be processed rapidly so as to avoid time losses. The COPRA® RF process chain also.

The COPRA RollScanner generates an accurate set of data of a roll's true shape. Scanned rolls can be compared immediately to the originally designed contour. This means no more "fire-fightings" due to unexpected and unnecessary long try-outs.Valley, 17.09.2024 The Bavarian company data M Sheet Metal Solutions GmbH is presenting the new version of COPRA RF with numerous innovations at EuroBLECH 2024. Highlights of Version 2025 include significant improvements to the Deformation Technology Module (DTM) and integration with Bricsys NV’s BricsCAD as an additional CAD system alongside .

Check out our metal german boxes selection for the very best in unique or custom, handmade pieces from our militaria shops.

data m sheet metal solutions|data m sheet metal products