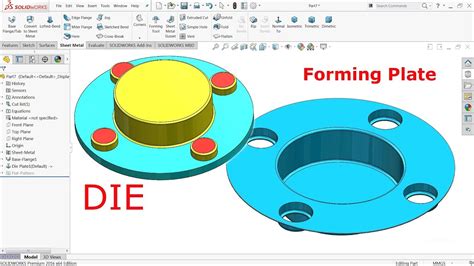

applying forming tools to sheet metal parts Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .

What is the metal thing boxers use on their face? The Enswell Eye Iron – The ‘must have’ item for any established boxing cutman. The Enswell is kept on ice before and throughout the fight. It’s then used to treat facial cuts and bruises throughout a fight, by reducing swelling and decreasing blood flow to the affected area.

0 · solidworks sheet metal stamping

1 · sheet metal forming solidworks

2 · sheet metal forming hand tools

3 · sheet metal forming by hand

4 · sheet metal fabricating tools

5 · forming tool sheet metal solidworks

6 · custom tooling for metal forming

7 · custom sheet metal forming

This article provides a grouping of Metal Gear Solid drawings and formulates a Yoji Shinkawa gallery of sorts. His work is best known for its usage in the series known as Metal Gear Solid. Drawings of Shinkawa's are used throughout the .

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design .

milwaukee electric sheet metal shears

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design .Forming tools from the Design Library are used only with sheet metal parts. Sheet .

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .

minature metal junction box with 7 8knockout

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes . This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a . This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a .

mill house metals

Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such .

Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the .Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes some sample forming tool parts to get you started. This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity.

solidworks sheet metal stamping

sheet metal forming solidworks

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision.

Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .

sheet metal forming hand tools

Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of .Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes some sample forming tool parts to get you started.

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity. This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision.

Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .

Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of .

milwaukee metal fabrication companies

milwaukee sheet metal nibblers

A cutman is a person responsible for preventing and treating physical damage to a fighter during the breaks between rounds of a full contact match such as a boxing, kickboxing or a mixed martial arts bout.

applying forming tools to sheet metal parts|sheet metal forming by hand