14 sheet metal screw shear strength To calculate LRFD values, multiply values in table by the ASD safety factor of 3.0 and multiply again with the LRFD Φ factor of 0.5. The lower of the allowable shear (bearing) and the .

Whether you're a seasoned artisan or a novice enthusiast, shop Woodcraft for expert advice, unbeatable prices, superior brands, and a woodworking experience like no other. Explore our .

0 · wood screw shear strength chart

1 · screws with high shear strength

2 · screw shear strength chart

3 · screw pull out strength chart

4 · machine screw shear strength chart

5 · deck screw shear strength chart

6 · best screws for shear strength

7 · 16d common nail shear strength

$0.81

Design of the connection must comply with Section J4 of AISI S100 (Section E4 of AISI S100 for the 2015 and 2012 IBC), using the nominal and allowable fastener tension and shear strength .This Technical Product Data Sheet provides the factored resistance of connections made with sheet metal screws calculated in accordance with CAN/CSA-S136-01 North American .

For steel-to-steel connections subject to shear, the lesser of the allowable fastener shear strength and the allowable shear (bearing) capacity found in Tables. 4 and 5, respectively, must be .P ss is the nominal shear strength of the screw and P ts is the nominal tensile strength of the screw. The safety factor Ω and resistance factor Φ are calculated based on AISI S100-07 Chapter F for tested connections.

Design Capacities for Sheet Metal Screws in Lightweight Steel Framing Applications This Technical Bulletin provided the factored resistance of connections made with sheet metal .To calculate LRFD values, multiply values in table by the ASD safety factor of 3.0 and multiply again with the LRFD Φ factor of 0.5. The lower of the allowable shear (bearing) and the .

Screw capacities are governed by a conservative estimate of screw capacity, not by sheet steel failure. For higher screw capacities, especially for screw strength, use specific .Quickly find the tensile, yield, proof, and estimated shear strengths of your bolts.

Screw shear strength is the average value, and tension strength is the lowest value listed in CFSEI Tech Note (F701-12). Higher values for screw strength (Pss, Pts), may be obtained by specifying screws from a specific manufacturer. Capacities based on the AISI S100 Specification Sections E2.4 for fillet welds and E2.5 for flare groove welds.

Design of the connection must comply with Section J4 of AISI S100 (Section E4 of AISI S100 for the 2015 and 2012 IBC), using the nominal and allowable fastener tension and shear strength for the screws, shown in Table 5.This Technical Product Data Sheet provides the factored resistance of connections made with sheet metal screws calculated in accordance with CAN/CSA-S136-01 North American Specification for the Design of Cold Formed Steel Structural Members,For steel-to-steel connections subject to shear, the lesser of the allowable fastener shear strength and the allowable shear (bearing) capacity found in Tables. 4 and 5, respectively, must be used for design.P ss is the nominal shear strength of the screw and P ts is the nominal tensile strength of the screw. The safety factor Ω and resistance factor Φ are calculated based on AISI S100-07 Chapter F for tested connections.

Design Capacities for Sheet Metal Screws in Lightweight Steel Framing Applications This Technical Bulletin provided the factored resistance of connections made with sheet metal screws calculated in accordance with CAN/CSA-S136-16 North American Specification for the Design of Cold Formed Steel Structural Members. This bulletin is intended as a .

gr2 titanium cnc precision machining

wood screw shear strength chart

To calculate LRFD values, multiply values in table by the ASD safety factor of 3.0 and multiply again with the LRFD Φ factor of 0.5. The lower of the allowable shear (bearing) and the allowable fastener shear strength found in Table 4 and 5, respectively must be used for design.Screw capacities are governed by a conservative estimate of screw capacity, not by sheet steel failure. For higher screw capacities, especially for screw strength, use specific screws from specific manufacturers. See manufacturers’ data for .

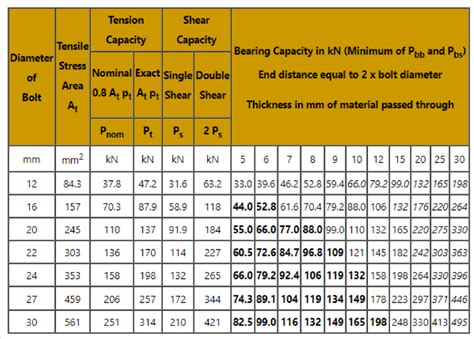

Quickly find the tensile, yield, proof, and estimated shear strengths of your bolts.Shear strength is a critical parameter that describes a screw’s ability to resist forces that cause it to slide or shear off at the point where it joins two materials. This measure is vital in ensuring the durability and safety of connections in construction projects.Screw shear strength is the average value, and tension strength is the lowest value listed in CFSEI Tech Note (F701-12). Higher values for screw strength (Pss, Pts), may be obtained by specifying screws from a specific manufacturer. Capacities based on the AISI S100 Specification Sections E2.4 for fillet welds and E2.5 for flare groove welds.

Design of the connection must comply with Section J4 of AISI S100 (Section E4 of AISI S100 for the 2015 and 2012 IBC), using the nominal and allowable fastener tension and shear strength for the screws, shown in Table 5.

This Technical Product Data Sheet provides the factored resistance of connections made with sheet metal screws calculated in accordance with CAN/CSA-S136-01 North American Specification for the Design of Cold Formed Steel Structural Members,For steel-to-steel connections subject to shear, the lesser of the allowable fastener shear strength and the allowable shear (bearing) capacity found in Tables. 4 and 5, respectively, must be used for design.P ss is the nominal shear strength of the screw and P ts is the nominal tensile strength of the screw. The safety factor Ω and resistance factor Φ are calculated based on AISI S100-07 Chapter F for tested connections.

Design Capacities for Sheet Metal Screws in Lightweight Steel Framing Applications This Technical Bulletin provided the factored resistance of connections made with sheet metal screws calculated in accordance with CAN/CSA-S136-16 North American Specification for the Design of Cold Formed Steel Structural Members. This bulletin is intended as a .To calculate LRFD values, multiply values in table by the ASD safety factor of 3.0 and multiply again with the LRFD Φ factor of 0.5. The lower of the allowable shear (bearing) and the allowable fastener shear strength found in Table 4 and 5, respectively must be used for design.

Screw capacities are governed by a conservative estimate of screw capacity, not by sheet steel failure. For higher screw capacities, especially for screw strength, use specific screws from specific manufacturers. See manufacturers’ data for .

Quickly find the tensile, yield, proof, and estimated shear strengths of your bolts.

screws with high shear strength

gp 1200 yamaha 1997 electrical box

The machining is excellent, the parts are absolutely perfect. They fit together .

14 sheet metal screw shear strength|screws with high shear strength