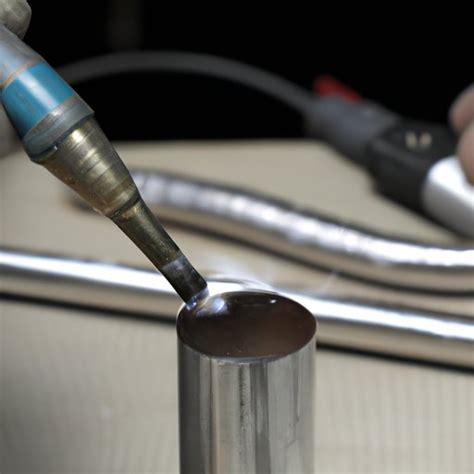

brazing aluminum sheet metal Aluminum brazing fluxes are specialized for use with aluminum and its alloys, ensuring efficient cleaning of surfaces and aiding in the wetting and spreading of the filler metal. They also help minimize porosity and defects in . Your first hand tool-based option when it comes to cutting metal is also among .

0 · metal brazing pros and cons

1 · how to braze metal together

2 · how strong is brazing

3 · can you braze galvanized steel

4 · brazing strength vs welding

5 · brazing steel with propane torch

6 · brazing stainless steel with propane

7 · brazing stainless steel sheet metal

Our reader Kay asks about the meaning of decorative stars seen on country homes and porches. We did some research and found some interesting facts behind these popular metal barn stars often seen on barns, farmhouses, country porches and even modern homes.

sheet metal fabrication stamping welding parts

Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air-conditioning . Aluminum brazing fluxes are specialized for use with aluminum and its alloys, ensuring efficient cleaning of surfaces and aiding in the wetting and spreading of the filler metal. They also help minimize porosity and defects in .

Aluminum brazing is a crucial method of connecting aluminum alloys and is known for its minimal deformation of the brazed parts. In recent years, it has gained widespread use in China due to its high dimensional .Aluminum brazing is a joining process that connects two aluminum parts using a filler metal with a lower melting point than the base material. The filler metal is heated until it melts and flows into the joint, where it solidifies and forms a .Brazing aluminum is a welding process that joins aluminum parts together by melting a filler metal into the joint. Once the filler metal has cooled and hardened, the joint is as strong as the base material. It is one of the most common .Aluminum brazing is a popular metal joining process in which the base metal is not melted, but joined through heating up aluminum brazing rods or fillers. Once it reaches the melting point, you can use it to either attach metal pieces together .

sheet metal fabrication table

Brazing aluminum will remove material and make how to join aluminum weaker than how it was originally; this makes how to brazed aluminum a cosmetic solution only that can be used for aesthetic purposes.Aluminum brazing is a process used to join aluminum alloys together using a filler metal, which typically has a melting point lower than the base metals. This technique is popular for its ability to produce strong, corrosion-resistant joints . Brazed aluminium joints generally between welded and soldered joints in strength and resistance to corrosion. Brazing of aluminium alloys was made possible by development of: aluminium-base fillers that have suitable . Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air-conditioning repairs. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage.

Aluminum brazing fluxes are specialized for use with aluminum and its alloys, ensuring efficient cleaning of surfaces and aiding in the wetting and spreading of the filler metal. They also help minimize porosity and defects in the brazed joint. A convenient method of preplacing filler metal is by using a brazing sheet (an aluminum alloy base metal coated on one or both sides). Heat treatable or core alloys composed mainly of manganese or magnesium are also used.

Aluminum brazing is a crucial method of connecting aluminum alloys and is known for its minimal deformation of the brazed parts. In recent years, it has gained widespread use in China due to its high dimensional accuracy.Aluminum brazing is a joining process that connects two aluminum parts using a filler metal with a lower melting point than the base material. The filler metal is heated until it melts and flows into the joint, where it solidifies and forms a bond between the two parts.Brazing aluminum is a welding process that joins aluminum parts together by melting a filler metal into the joint. Once the filler metal has cooled and hardened, the joint is as strong as the base material. It is one of the most common methods for joining this metal.Aluminum brazing is a popular metal joining process in which the base metal is not melted, but joined through heating up aluminum brazing rods or fillers. Once it reaches the melting point, you can use it to either attach metal pieces together or fill .

Brazing aluminum will remove material and make how to join aluminum weaker than how it was originally; this makes how to brazed aluminum a cosmetic solution only that can be used for aesthetic purposes.Aluminum brazing is a process used to join aluminum alloys together using a filler metal, which typically has a melting point lower than the base metals. This technique is popular for its ability to produce strong, corrosion-resistant joints while maintaining good appearance and strength.

Brazed aluminium joints generally between welded and soldered joints in strength and resistance to corrosion. Brazing of aluminium alloys was made possible by development of: aluminium-base fillers that have suitable melting ranges.

Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air-conditioning repairs. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Aluminum brazing fluxes are specialized for use with aluminum and its alloys, ensuring efficient cleaning of surfaces and aiding in the wetting and spreading of the filler metal. They also help minimize porosity and defects in the brazed joint. A convenient method of preplacing filler metal is by using a brazing sheet (an aluminum alloy base metal coated on one or both sides). Heat treatable or core alloys composed mainly of manganese or magnesium are also used. Aluminum brazing is a crucial method of connecting aluminum alloys and is known for its minimal deformation of the brazed parts. In recent years, it has gained widespread use in China due to its high dimensional accuracy.

Aluminum brazing is a joining process that connects two aluminum parts using a filler metal with a lower melting point than the base material. The filler metal is heated until it melts and flows into the joint, where it solidifies and forms a bond between the two parts.Brazing aluminum is a welding process that joins aluminum parts together by melting a filler metal into the joint. Once the filler metal has cooled and hardened, the joint is as strong as the base material. It is one of the most common methods for joining this metal.Aluminum brazing is a popular metal joining process in which the base metal is not melted, but joined through heating up aluminum brazing rods or fillers. Once it reaches the melting point, you can use it to either attach metal pieces together or fill .

Brazing aluminum will remove material and make how to join aluminum weaker than how it was originally; this makes how to brazed aluminum a cosmetic solution only that can be used for aesthetic purposes.Aluminum brazing is a process used to join aluminum alloys together using a filler metal, which typically has a melting point lower than the base metals. This technique is popular for its ability to produce strong, corrosion-resistant joints while maintaining good appearance and strength.

metal brazing pros and cons

how to braze metal together

how strong is brazing

In this article, we will explore the factors to consider when selecting a fabric-to-metal glue, the types of glue available, how to apply the glue correctly, and even alternative ways to attach fabric to metal.

brazing aluminum sheet metal|brazing stainless steel sheet metal