cnc machine axis pdf designs can be made quickly and affordably using 3-axis machines, while 5-axis machines are better for creating geometrically complex pieces with increased speed and accuracy. When considering steel framing studs versus wood for your tiny house, It’s essential to understand the standard sizes of steel studs. This offers versatility and ease of installation. However, it’s important to weigh the pros and cons of using steel studs.

0 · cnc with rotary axis

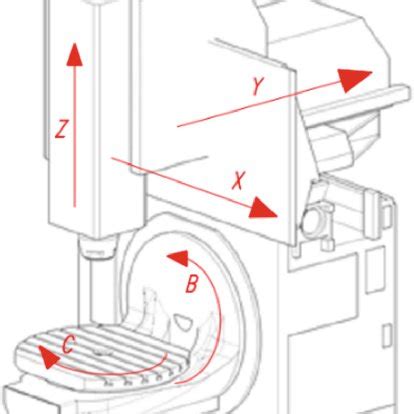

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

What even is a junction box, and how does one work? The Spruce explains that a junction box — also called an electric box — is where two or more electrical wire connections meet into one behind a plastic or metal protective container.

Displays a number, typically an axis coordinates value. What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. .With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically .

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .

flameproof junction box price

• Power up machine properly • Machine home position of the MCS • Select “zero-return” or “home” mode on control panel • Jog each axis towards home position • Most machines will .designs can be made quickly and affordably using 3-axis machines, while 5-axis machines are better for creating geometrically complex pieces with increased speed and accuracy.CNC machines can be purpose built as a 3+1 or 3+2 axis mill, but more commonly, they are created by adding a rotating component to an existing 3-axis mill. The latter method will .5-axis machines, providing features to allow machine and tool independent part programs to be generated. Software available from many CAD/CAM providers will support the requirements of .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .

cnc with rotary axis

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.Use the method that is exhibited on the buildyourcnc.com website to drive the nuts into these holes. 3 connect through the the main 4" piece being attached, and two motor mounts. The .

Displays a number, typically an axis coordinates value. What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like

• Power up machine properly • Machine home position of the MCS • Select “zero-return” or “home” mode on control panel • Jog each axis towards home position • Most machines will automatically complete the procedure • Machine will zero the machine coordinate systemdesigns can be made quickly and affordably using 3-axis machines, while 5-axis machines are better for creating geometrically complex pieces with increased speed and accuracy.

CNC machines can be purpose built as a 3+1 or 3+2 axis mill, but more commonly, they are created by adding a rotating component to an existing 3-axis mill. The latter method will reduce the work envelop size, so that should be taken into consideration when outfitting a mill.

5-axis machines, providing features to allow machine and tool independent part programs to be generated. Software available from many CAD/CAM providers will support the requirements of 5-axis programming for FANUC CNCs.G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

Use the method that is exhibited on the buildyourcnc.com website to drive the nuts into these holes. 3 connect through the the main 4" piece being attached, and two motor mounts. The large center hole is simply to allow space for the couplings and if the bearing is not flush against the main piece. There are six of these pieces onthe machine.Displays a number, typically an axis coordinates value. What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

flanging in sheet metal

With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like• Power up machine properly • Machine home position of the MCS • Select “zero-return” or “home” mode on control panel • Jog each axis towards home position • Most machines will automatically complete the procedure • Machine will zero the machine coordinate systemdesigns can be made quickly and affordably using 3-axis machines, while 5-axis machines are better for creating geometrically complex pieces with increased speed and accuracy.

CNC machines can be purpose built as a 3+1 or 3+2 axis mill, but more commonly, they are created by adding a rotating component to an existing 3-axis mill. The latter method will reduce the work envelop size, so that should be taken into consideration when outfitting a mill.5-axis machines, providing features to allow machine and tool independent part programs to be generated. Software available from many CAD/CAM providers will support the requirements of 5-axis programming for FANUC CNCs.

cnc machine axis locations diagram

cnc machine axis direction

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

flameproof control panel junction box manufacturers thane maharashtra

cnc axis explained

CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.

cnc machine axis pdf|cnc axis explained