cnc 4 axis machine Inventables X-Carve Pro 4×4 is the best choice for most people looking to invest in a 4×4 CNC machine for their small business. It offers unparalleled speed, accuracy, and precision, with easy setup and a wide . The most common processes for thin metal welding are TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). TIG welding is ideal for thin metals as it offers precise control over the heat input, which is essential for preventing warping or burn-through.

0 · hobby 4 axis cnc machine

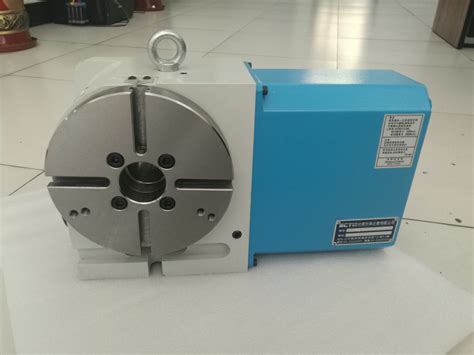

1 · cnc 4th axis rotary

2 · best 4 axis cnc machines

3 · 4th axis for cnc mill

4 · 4 axis hobby cnc

5 · 4 axis cnc woodworking machines

6 · 4 axis cnc mill cost

7 · 4 axis cnc machine price

This highly interactive write-in workbook covers all the essential aspects of level 1 and 2 Welding & Fabrication theory including thorough QCF unit coverage of welding processes, metal fabrication & thermal cutting, as well as engineering materials & operations.

In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts. A typical CNC router only has three axes and moves the cutting tool in .Unlike traditional 3-axis machines, the 4-axis CNC router allows for more complex and intricate cuts. This added axis enables the router to rotate around the X, Y, and Z axes simultaneously, . 3-axis CNC routers are standard, so take your making to the next level with a 4-axis one! Read on to see the best 4-axis CNC router options. Inventables X-Carve Pro 4×4 is the best choice for most people looking to invest in a 4×4 CNC machine for their small business. It offers unparalleled speed, accuracy, and precision, with easy setup and a wide .

The best 4 axis CNC routers have better, more flexible manufacturing capabilities – but they’re more expensive than standard 3-axis hobbyist CNCs. In this article, I’ll recommend the best 4-axis CNCs for every use, from basic hobbyist . In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts. A typical CNC router only has three axes and moves the cutting tool in the X, Y, and Z axes to remove material from the stock.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. 4 axis CNC machines: More flexible and accurate. Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type. Can produce complex 3D shapes and angled features. Choosing a CNC machine: Depends on your project needs, budget, and desired level of detail.

metal fabrication williamsport pa

Unlike traditional 3-axis machines, the 4-axis CNC router allows for more complex and intricate cuts. This added axis enables the router to rotate around the X, Y, and Z axes simultaneously, making it ideal for creating sophisticated designs. 3-axis CNC routers are standard, so take your making to the next level with a 4-axis one! Read on to see the best 4-axis CNC router options. Inventables X-Carve Pro 4×4 is the best choice for most people looking to invest in a 4×4 CNC machine for their small business. It offers unparalleled speed, accuracy, and precision, with easy setup and a wide range of software compatibility.Our LU3000 EX turning center is Okuma's latest evolution of 4-axis turning in the 8- to 10-inch chuck class. Two tools at work simultaneously provide process flexibility as well as high removal rates.

A 4 axis CNC router operates on the X, Y, and Z axes like a 3-axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process. 4th Axis Ready; CANCAM B1-44 M CNC Router. The Canadian based company CANCAM, not to be confused with CAD/CAM, offers a 4×4 CNC router of their own. Designed with woodworkers and professionals in mind, the B1-44 offers a dynamic TBI ball screw drive for precision machining. The best 4 axis CNC routers have better, more flexible manufacturing capabilities – but they’re more expensive than standard 3-axis hobbyist CNCs. In this article, I’ll recommend the best 4-axis CNCs for every use, from basic hobbyist . In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts. A typical CNC router only has three axes and moves the cutting tool in the X, Y, and Z axes to remove material from the stock.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

4 axis CNC machines: More flexible and accurate. Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type. Can produce complex 3D shapes and angled features. Choosing a CNC machine: Depends on your project needs, budget, and desired level of detail.

Unlike traditional 3-axis machines, the 4-axis CNC router allows for more complex and intricate cuts. This added axis enables the router to rotate around the X, Y, and Z axes simultaneously, making it ideal for creating sophisticated designs. 3-axis CNC routers are standard, so take your making to the next level with a 4-axis one! Read on to see the best 4-axis CNC router options. Inventables X-Carve Pro 4×4 is the best choice for most people looking to invest in a 4×4 CNC machine for their small business. It offers unparalleled speed, accuracy, and precision, with easy setup and a wide range of software compatibility.Our LU3000 EX turning center is Okuma's latest evolution of 4-axis turning in the 8- to 10-inch chuck class. Two tools at work simultaneously provide process flexibility as well as high removal rates.

A 4 axis CNC router operates on the X, Y, and Z axes like a 3-axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process.

hobby 4 axis cnc machine

Welding sheet metal is one of the manufacturing industry’s basic processes for joining metals. The process usually requires heating the two pieces of sheet metal up to the melting point, then using a torch to weld them together.Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn .

cnc 4 axis machine|4 axis cnc mill cost