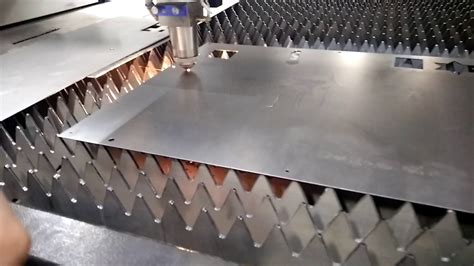

useful thing laser cut out of sheet metal Sheet metal laser cutting machinery uses one of three types of lasers: C02 Laser: This laser is ideal for cutting, boring, and engraving on metal. These lasers cut mild steel, . How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.

0 · wholesale sheet metal laser cutting

1 · sheet metal cutting near me

2 · laser metal cutting near me

3 · laser cut website

4 · hobby laser cutter for metal

5 · desktop laser cutter for metal

6 · best sheet metal laser cutter

7 · 24x24 sheet metal laser cutter

Typically a key is made of metal with grooves and notches cut into it. Most keys have two parts – the bit and the bow. The key bit is the part that enters the lock, and the bow is the part that is left protruding from the keyhole on which the key user applies pressure to turn the key and operate the lock.

I'm interested in cutting small simple shapes from aluminum thin sheet metal. I plan to cut perimeter shapes and score lines to allow bending the pieces into simple open box / consolet type enclosures. Sheet metal laser cutting machinery uses one of three types of lasers: C02 Laser: This laser is ideal for cutting, boring, and engraving on metal. These lasers cut mild steel, .

Custom signs. This is probably one of the most popular laser cutting ideas for online crafters and artists. However, you can make your signs stand out by not only creating . Steel shim sheets in thicknesses from one to eight-thousandths of an inch appeared to be perfectly cuttable, with an appropriate air assist and speed settings, with thicker sheets needing a.

Sheet metal laser cutting harnesses the power of concentrated light to cut through metal precisely and efficiently. Read on to discover how sheet metal laser cutting is indispensable to the automotive, aerospace, and electronic industries. The top 8 advanced tips and tricks to getting the perfect results for your custom metal laser cut project. Ideal for manufacturers and engineers. Here's how to plan your laser design file and get the highest quality steel or . Understanding Laser Cutting and Its Application on Sheet Metal. Laser cutting technology, with its precise and efficient method, utilizes intricate cuts made by diode laser or state-of-the-art kilowatt-level lasers to slice . It will eventually form a large skull (about 12" tall, 14" deep) when it's done. I've made one out of paper and am now attempting to make one out of sheet metal. I have some 20ga and 24ga cold-rolled for options. I've printed .

It comes as a frame which you deform to put tension on the blade before tightening down the screws which hold it in place. They use special very thin blades which you get in packs of a dozen. You need at least 2 teeth to engage in the thickness of the metal or the blade won't cut it, so you need to measure the sheet metal and buy blades .

Hi all, New to the forums here hoping to get a little advice. I make jewellery and looking for a more efficient way to cut shapes out of sheet metal. I'm. How to install the app on iOS. . The fiber laser is what you generally need for laser cutting metal. And that can be expensive. C. cadefoster84 Plastic. Joined Apr 1, 2020. Apr 1, 2020 #7

Such laser cutters are ideal for cutting thin sheets of material such as acrylic, wood, and paper, but rarely useful for cutting metal. Desktop laser cutters are perfect for rapid prototyping of new ideas and concepts, creating custom laser .There are many ways to create custom sheet metal forms, two of the most popular methods using either metal stamping or laser cutting machines. These machines are used to create custom metal products for all sorts of purposes. . This laser is made of an energy emission device that puts out high concentrations of photon streams. This is .Sheet metal would reflect the laser back up onto the bottom of the work peice. Ideally, you want a honeycomb bed, then a few inches underneath that, a sacrificial layer. . If you intend to cut materials with it, like thin plywood or whatnot - i'd put it on a wire rack (like what you have in ovens) but the wire rack still will rest on top of . Automation: Many new laser systems use CNC (Computer Numerical Control) to optimize cutting paths and cut down on manual tweaks, making the process even faster. Misconception 3: For certain Materials Another common mistake is thinking laser cutting works on certain materials.

IME theres no free ride on this one, its arguably the most involved part of the laser cutting process, getting thoes tags as small as reliably possible really helps though + were they are on any given part, its not so bad for big bits, but these days its rare any of my parts are bigger than a half dozen square inches of sheet so im sure my laser supplier is cursing me out under . The minimum spacing should be equal to the thickness of the material. For example, in sheet metal laser cutting, if sheet metal is 2 mm thick, the spacing between two paths be 2 mm. It is also important if you are looking at working on different laser cut sheet metal designs. Convert Your Text Into Anchor Points and Curves Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”. I have seen a few metal cutting tools, such as snips and nibblers, but they cut through the metal to get to their point of interest, which I only want the lettering to be cut. I have also read that laser/water-cutting nozzles can get caught in stamped grooves, which could damage the nozzles, so that option is out.

Unlike CO 2 lasers, fiber lasers have no moving parts or mirrors to go out of whack, yielding lower maintenance costs. Best of all, fiber lasers use less electricity for the same cutting power. . Laser Cutting Service for Sheet Metal Parts. Analog and digital manufacturing technologies have merged in the form of laser/punch machines. These .A custom metal cutting service, like TNN Engineering, can also help with the creation of the design. Cutting the design on the sheet metal can be done by manually operating the laser cutter or connecting it to a Computer Numerical Control (CNC) system. A CNC laser cutting machine can read intricate designs and produce a precise cut or engrave . The cut-up skeleton fits snugly in the hopper, and the operator can get back to loading another sheet for the next job. The same principles of skeletal cutting apply to fiber lasers, but because of the high speed at which these machine tools cut, the fabricator almost always chooses to use some sort of automation for material handling, Arteaga .

Assuming you are making various designs of a similar product, clearly this is a gigantic advantage since you can ensure that each and every thing comes out precisely similar.This lessens the likely measure of waste you are managing, .This sub is for tool enthusiasts worldwide to talk about tools, professionals and hobbyists alike. We welcome posts about "new tool day", estate sale/car boot sale finds, "what is this" tool, advice about the best tool for a job, homemade tools, 3D printed accessories, toolbox/shop tours.Well, the same thing happens with the machining of parts. You need to know the machines you have. Go out to the factory, talk to the operators, observe with them the machining of a complete sheet metal job and ask their opinion. It is .

The most important thing to keep in mind when you’re painting laser cut parts at home is to properly prepare the metal. If you aren’t having your parts abrasion blasted in preparation, you should brush them with an abrasive material like scotch brite and then wash the parts in acetone or alcohol. PREVENTING WARPING IN LASER CUT COMPONENTS. When it comes to laser cutting flat panels, the more material being removed over a certain area, the more likely warping is to occur. Grill-like mesh shapes or long, thin shapes are most likely to .

wholesale sheet metal laser cutting

sheet metal cutting near me

Freshly cut sheet metal can be extremely sharp, so use protective gloves and work carefully when cutting with tin snips. After cutting to size, frame the sheet with wood trim. Or if the edges will be exposed, crimp or fold them over using clamps to hold the sheet to the edge of a workbench, and then hammer down the borders with a wooden mallet.

Discover the 6 common ways to cut sheet metal for fabrication and find out how laser cutting, plasma cutting and more can help to achieve great results. Skip to content. Home; About. Profile; Milestone; . Laser cutting is a fashionable technique of cutting sheet metal using laser beams whereby metal is cut with superb precision. This method . So I've installed a 'stencil font', create a sketch on the surface I want laser cut letters in my sheet metal, then exit the sketch but the cut command says there is an error, no valid closed loops suitable in sketch. Any suggestions, do I need to explode the text? I have no issues doing this in solid objects, just sheetmetal issue. p.s.

laser metal cutting near me

Benefits of Laser-Cut Metal. The advantages of laser metal cutting extend far beyond mere aesthetics. Here are just a few of the benefits that have made laser metal cutting the go-to choice for metalworkers: Precision: Laser cuts are razor-sharp and burr-free, eliminating the need for extensive post-processing. This remarkable precision is .

laser cut website

As someone who has cut thousands of parts with a laser I very much disagree that “slicing through either one like butter isn’t a thing”. Powerful lasers can and do cut through metal every day. I have 3/4” thick steel in my living room that was cut by a laser. Not sure of the maximum thickness that lasers can cut steel but I’m sure it .Find and save ideas about laser cut metal on Pinterest. Modern CNC laser cutting machines combine this technology with an extremely precise motion control system, allowing the laser head to cut out shapes in a wide range of metal sheet. What metals can be laser cut? One of the big advantages to laser cutting, is that almost any material can be cut, from thin metals to thick ones, as well as wood and . Laser cutting has revolutionized the sheet metal industry, providing unmatched precision and cutting speed. In this guide, we'll help you navigate the world of sheet metal laser cutting machines, highlighting the key factors you need to consider when making your selection. Whether you're an experienced industry player or a novice.

hobby laser cutter for metal

Octagon (ceiling) box screws are 8-32. Wall box screws are 6-32. Fan support box screws and ground connection screws are 10-32. Both ceiling and wall box screws are .

useful thing laser cut out of sheet metal|wholesale sheet metal laser cutting