how to weld sheet metal with oxy acetylene We need to make some repairs on the fender for our '71 Chevy pickup project. Just for fun let's do this old school, by torch welding it. email: ratzlaffmotor. Standard electrical box screws typically have a diameter of #6 (3.5mm) or #8 (4mm). For smaller junction boxes, #6 screws with a length of 0.75 to 1 inch (19 to 25mm) are commonly used. However, for larger junction boxes, you may need to use #8 screws or even longer screws to ensure a secure fit.

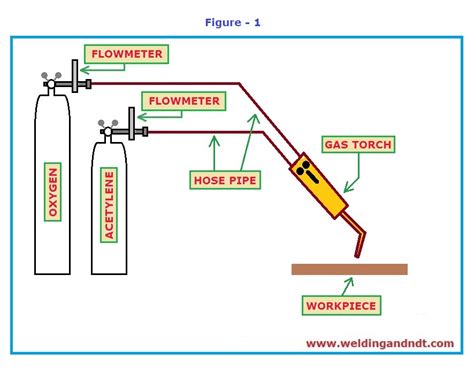

0 · oxygen acetylene welding system diagram

1 · oxy acetylene welding tip chart

2 · oxy acetylene welding rod chart

3 · oxy acetylene welding pressure chart

4 · oxy acetylene welding instructions

5 · oxy acetylene welding for beginners

6 · oxy acetylene welding diagram

7 · oxy acetylene gas welding diagram

A junction box, also known as an electrical junction box or junction can, is an enclosure that connects and splits electrical wires and cables. Junction boxes permit access to .

This video walks you through the old school technique of brazing sheet metal with an oxygen acetylene torch and also shows welding steel with an oxygen acety. We need to make some repairs on the fender for our '71 Chevy pickup project. Just for fun let's do this old school, by torch welding it. email: ratzlaffmotor. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the advantages and disadvantages of using this method. Whether you’re a beginner or a seasoned . Oxy-acetylene welding depends on ignited oxygen and acetylene gas to produce flame that is capable of melting and fusing metals. Depending on the flame control, it is easy to change the heat and therefore use the .

This is just to show the basic setup and how to manipulate metal with heat. Proper penetration and better welds are taug.more. Video for my high school students to follow as they learn. Oxy-Acetylene welding is a tried and true method for fusing metals and a great way to get started with welding. Here's how the process works and how to take the proper safety precautions before you begin. Oxygen-acetylene welding is the only gas welding procedure that can weld hard and high melting point metals, including steel. Moreover, steel has a melting point of 1500 degrees Celsius which we can’t get by burning various .Prepare the parts. The first step is to prepare the parts that will be joined. This involves carefully cleaning the surfaces of the metals and removing any traces of dirt, oil or paint. Thorough scrubbing with an abrasive will also create .

Oxy-acetylene welding, a type of gas welding also known as oxyfuel welding, is primarily used for welding thin metal sections and can also be used for heating tasks. Welding with oxy-acetylene is a flexible and forgiving . NAIT Video describing how to safely weld with an Oxy-Acetylene torch, flux and filler metal.All rights to this video belong to Northern Alberta Institute of . https://www.tinmantech.comAluminum Gas Welding Flux- https://www.tinmantech.com/html/aluminum_welding_supplies.php#3See how a simple oxy-acetylene torch weld. A rough guide to welding aluminium sheet using oxy acetylene gas.Special parts required:Type 5 gas nozzleAluminium flux Blue or special green lens - blue len.

Oxy-Acetylene Gas Welding, Brazing and Braze Welding These are older methods of joining thin metal sections that still have some application in today’s world of (mostly) electric welding. In most cases they will prove inferior, in one or . Welding with oxygen acetylene is as simple as 1-2-3. First, sculptor Kevin Caron shares how to get your torch set right and what kind of rod to use. Second, .So, you need to cut some metal. Maybe you’re fitting some joints together on your latest welding project. Or that piece of sheet metal is just a few inches too long. No matter the reason, welding often involves making cuts into metal. . Some of the most popular in the welding world are plasma cutting and oxy acetylene cutting. Both types of .

Sheet Metal Welding By The Oxy-Acetylene Process is a comprehensive guide to the art of welding sheet metal using the oxy-acetylene process. The book is written by Thomas Cook Fetherston, an experienced welder and teacher, and provides a detailed introduction to the tools and techniques involved in this type of welding.The book begins with an overview of the oxy .

oxygen acetylene welding system diagram

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Oxygen Acetylene Gas Welding with the Oxygen Acetylene Torch. Two types of welds: Fusion welding and Gas Welding using RG 45 gas filler rod. julie, gotta agree with Hobweld. I've cut 16, 18, 20 ga with a 0 tip and done pretty good at it too. Normal gauge settings, normal heat range, just lay it over and travel pretty fast.There is less tendency for the mat to re-weld itself and you can get a nice straight line.A lot of times on custom handrail tubing you need to make mitred, beveled,compound angled mutha .

Kevin uses a rosebud tip on his acetylene torch to heat up solid 1-inch steel rods so he can shape them for a public sculpture. He heats a section of the rod.OA is the poor man's TIG in my opinion. I've welded down to 18 gauge sheet metal with a 00 tip and now that I've got a jewelers torch I can weld razor blades together. I've made blacksmithing hammers from mild steel and hard faced them with 1080 on the striking face. Hi I'm starting out doing repairs on thin sheet metal (1mm) and getting conflicting info re pressure. The table in my BOC welding guide suggests .14 BAR. Home MIG TIG Arc Paint Forum. . pressure for oxy acetylene welding thin sheet. Thread starter foy9999; Start date Apr 17, 2023; foy9999 Member. Messages 300 Location East Kilbride. To braze and weld with oxy acetylene, you need to master the correct techniques and safety measures. In this guide, we will discuss the steps and tips to execute a proper oxy acetylene welding. Oxy acetylene welding is a process that involves joining metals together with the help of heat and a filler metal.

Oxy-acetylene welding cutting, plasma cutting, brazing Learn with flashcards, games, and more — for free. . The plasma cutter is good for cutting old car sheet metal because it will cut any metal you are likely to run across with little heat distortion. It also is not overly picky about the cleanliness of the surface as long as your ground . Victor 250 Oxy-Acetylene Rig (welding and cutting) Bobcat 773 F-350, 1999, 4x4, 16' 10K# trailer Outdoor Wood Burner - 10 cords/year. Reply . 06-27-2011 #3. Absinthe. . but when I say plug weld I mean a case where you drill a hole in the sheet metal and weld it to a frame member beneath that hole, joining the edges of the hole to the frame . Took this video in 2009, practicing oxy-fuel, was just learning here, I know the bead isn't great! I believe that the rod was 1/16 mild steel, #4 tip 1/8 she. Learn how to use an oxy acetylene set up to cut metal.Sign up for the email list. Grab some great tools and supplies while supporting the channel @:https://w.

Oxy-acetylene welding ( generally known as oxygen-acetylene welding, oxy welding, or gas welding in the US ) is the process that involves the burning of oxygen and acetylene, which is a hydrocarbon. An ultimate 3200 degrees Celsius can be achieved when oxygen and acetylene in the hand-held torch are mixed in the right amount. Other welding techniques that are effective for aluminum include TIG (tungsten inert gas) welding and MIG (metal inert gas) welding. However, unlike these, oxy-acetylene, or arc welding, is much more widely used since it is relatively inexpensive and has equipment that is typically much more portable than TIG or MIG welding plants. how to weld Thin expanded metal to thick steel rods using an acetylen and oxygen torch. Tom Gingras continues to work on his fiddler on the roof sculpture a.

oxy acetylene welding tip chart

TIG (Tungsten Inert Gas) welding: Offers greater precision and control, making it an ideal choice for welding thin metal. Oxy-acetylene welding: Allows for precise heat control and can be suitable for thin metal applications. Spot welding: A method designed specifically for joining thin sheets of metal without the need for filler material. Oxygen acetylene welding, or oxy acetylene welding, is a process for joining metals that was introduced in 1903 by Thomas Wilson. Temperatures from the combustion of oxygen (O2) gas and ethyne, or acetylene (C2H2) gas can reach 3,340 degrees Celsius, which is hot enough to cut through steel. . Welding involves the joining of metal objects via .Help with oxy acetylene + filler metal welding Need Help Locked post. New comments cannot be posted. Share Sort by: Best. Open comment sort options. Best. Top. New . of it being used in is antique aircraft welding and some custom auto body shops because they can bend and shape the sheet metal as they're welding. So warping isn't as much of a .How to cut metal with Oxy-acetylene welding.#shortsvideo #weldingtools #fabrication #gas #oxygen #carbon #love #life #like #share #shorts#trending #viralvide.

Oxy Welding. Oxy-Fuel welding (OFW) is a group of welding processes that join metals by heating them with a fuel gas flame or flares with or without the application of pressure and with or without the use of filler metal. Oxy Fuel welding includes any welding operation that makes use of a fuel gas combined with oxygen as a heating medium.

oxy acetylene welding rod chart

oxy acetylene welding pressure chart

Sheet metal manufacturers use different types of welding methods for sheet metal fabrication. The method chosen differs as per the metal being fabricated and the desired end product. Here is a look at the different types of welding methods used in sheet metal fabrication: Gas Metal Arc Welding (GMAW)For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. The Reboot MIG welder supports both flux-cored and solid wires.

how to weld sheet metal with oxy acetylene|oxy acetylene welding diagram