drawability of sheet metal Besides the flow curve and plastic anisotropy, the formability of a material inclu des the capability to undergo plastic deformation to a given shape without defects. The defects have to be . Buy Metal Pencil Box s at Walmart.com

0 · sheet metal forming limitations

1 · formability of sheet metal

2 · deep drawing sheet metal

Queen-Size-Box-Spring, 9 inch Box Spring Queen Box Spring Queen Only High Profile,Metal Mattress Foundation,Easy to Assemble,Heavy Duty,No Squeaky,with Box Spring Cover 8 4.4 out of 5 Stars. 8 reviews

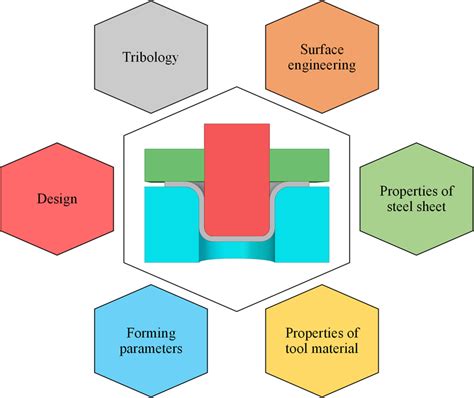

Formability of sheet metal is the ability of sheet metal to be drawn into cups or formed into the desired shapes without any defect. However, in order to have a measure for sake of comparison, the limit drawing ratio (LDR) is taken as a measure of drawability. The formability is the capability of sheet metal to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal forming procedures of deep .Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw .Besides the flow curve and plastic anisotropy, the formability of a material inclu des the capability to undergo plastic deformation to a given shape without defects. The defects have to be .

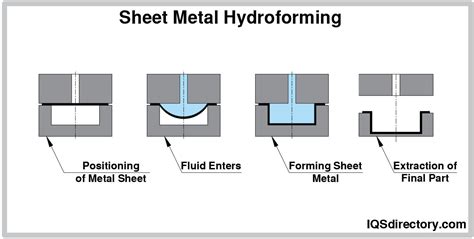

Drawing is the sheet metal forming process where the punch that creates the part shape forces the sheet metal to pull in from the flange area. In contrast with stretch-drawing or stretch forming, little metal thinning occurs in pure drawing. It is thereby possible to better understand and control the drawing limit of sheet metal in industry necessity. 1. Whiteley, R. L., 1960, “The Importance of Directionality in .Sheet metal is drawn in either hydraulic or mechanical presses. The article summarizes the defects in drawing and factors considered in press selection for drawing. It explains the types . Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic Bulge Test,.

The formability of sheet metal can be defined as the ability of a sheet to be drawn into cups or other desired shapes. It depends upon several factors such as yield strength, strain hardening.Formability of sheet metal is the ability of sheet metal to be drawn into cups or formed into the desired shapes without any defect. However, in order to have a measure for sake of comparison, the limit drawing ratio (LDR) is taken as a measure of drawability. The formability is the capability of sheet metal to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal forming procedures of deep-drawing and stretching.Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006).

Besides the flow curve and plastic anisotropy, the formability of a material inclu des the capability to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal . The plastic strain ratio, r, is considered a direct measure of sheet metal's drawability and is useful for evaluating materials intended for forming shapes by deep drawing (see lead photo).

Drawing is the sheet metal forming process where the punch that creates the part shape forces the sheet metal to pull in from the flange area. In contrast with stretch-drawing or stretch forming, little metal thinning occurs in pure drawing. It is thereby possible to better understand and control the drawing limit of sheet metal in industry necessity. 1. Whiteley, R. L., 1960, “The Importance of Directionality in Drawing Quality Sheet Steel,” Trans., ASM, 52, pp. 154–163. 2.Sheet metal is drawn in either hydraulic or mechanical presses. The article summarizes the defects in drawing and factors considered in press selection for drawing. It explains the types of dies used for drawing sheet metal and the effects of . Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic Bulge Test,.

The formability of sheet metal can be defined as the ability of a sheet to be drawn into cups or other desired shapes. It depends upon several factors such as yield strength, strain hardening.Formability of sheet metal is the ability of sheet metal to be drawn into cups or formed into the desired shapes without any defect. However, in order to have a measure for sake of comparison, the limit drawing ratio (LDR) is taken as a measure of drawability. The formability is the capability of sheet metal to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal forming procedures of deep-drawing and stretching.

Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006).Besides the flow curve and plastic anisotropy, the formability of a material inclu des the capability to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal . The plastic strain ratio, r, is considered a direct measure of sheet metal's drawability and is useful for evaluating materials intended for forming shapes by deep drawing (see lead photo).

Drawing is the sheet metal forming process where the punch that creates the part shape forces the sheet metal to pull in from the flange area. In contrast with stretch-drawing or stretch forming, little metal thinning occurs in pure drawing. It is thereby possible to better understand and control the drawing limit of sheet metal in industry necessity. 1. Whiteley, R. L., 1960, “The Importance of Directionality in Drawing Quality Sheet Steel,” Trans., ASM, 52, pp. 154–163. 2.Sheet metal is drawn in either hydraulic or mechanical presses. The article summarizes the defects in drawing and factors considered in press selection for drawing. It explains the types of dies used for drawing sheet metal and the effects of . Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic Bulge Test,.

china junction box suppliers

sheet metal forming limitations

formability of sheet metal

deep drawing sheet metal

Shop for Steel Cabinets & Chests in Entryway Furniture at Walmart and save.

drawability of sheet metal|formability of sheet metal