lap seam sheet metal Typical installation details require that side laps of the roof panels are screwed together with sheet metal “stitching” screws. If snow, ice, or water accumulates, the only defense the lap seams have against water intrusion is . In fact, I noticed a number of doubled-up wires. I believe that this box allows two grounding wires under a single lug. I know that two neutrals are not allowed. I have to add several breakers (box will then be full) and would like to to tidy it a little when I do so.

0 · types of sheet metal seams

1 · sheet metal seams pdf

2 · sheet metal lap joint tool

3 · safety edge for sheet metal

4 · lap seam metal roof panels

5 · interlocking sheet metal joints

6 · interlocking sheet metal design

7 · grooved seam sheet metal

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

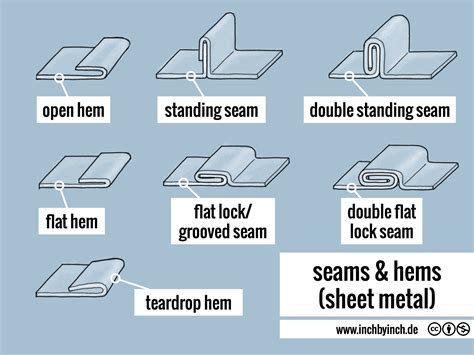

Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER .

Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork. Doing another 'back to basics' here for a couple of videos on the step by step "how to" for coppersmithing / tinsmithing / sheet metal seams. Typical installation details require that side laps of the roof panels are screwed together with sheet metal “stitching” screws. If snow, ice, or water accumulates, the only defense the lap seams have against water intrusion is . Lap seam welding is an excellent welding option for liquid and gaseous joints. You can use continuous seam welding to produce air and liquid tight radiators, tin cans, dishwashers, washing machines, and other steel drums.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. .Bend every other tab out to form a shoulder on the outside of the flat sheet metal 3.Insert the pipe into the hole that has been cut for the pipe 4. Hammer over the remaining tabs to hold the pipe in place. 1 / 13. 1 / 13. Flashcards; Learn; Test; . some ways lap seams can be jointed together. Lap seams can be welded, spot welded, riveted .

I have done both,,the only time I will lap weld if everything has been sandblasted and is clean sheet metal,,of course it's always best to have clean sheet metal whether you lap or butt weld. HRP HOTRODPRIMER, Feb 2, 2013. . I but weld almost everything except where a lap on a factory seam is. To do a panel properly the fit is very important .A variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. . The lap seam is a basic metal seam where one piece overlaps the other. A "lap" is created by making a fold across the edge, then laying the lap over the other piece of metal, pounding flat and soldering, welding or .

Our exposed fastener metal panels offer an ideal roof and/or wall application for commercial, industrial, and architectural buildings. ICC-ESR #5045 with CB . Call us Toll Free at 1-800-574-1388

Chapter #6 – Sheet Metal Joints Rectangular Duct Joints TDC – Transverse Duct Connector (SMACNA T-25A) This traverse duct connector is fabricated from the same piece of metal as the duct (#3), and has a gasket (#10) inserted between the two joints of duct or fitting and is locked in place by a cleat (#9).Our exposed fastener metal panels offer an ideal roof and/or wall application for commercial, industrial, and architectural buildings. ICC-ESR #5045 with CB . Call us Toll Free at 1-800-574-1388 Create an "offset hem" or "countersunk lap seam" in SE with Sheet Metal garmancm (Mechanical) (OP) 8 Sep 16 11:17. I've used inventor quite a bit, and am able to create what I believe is called an offset hem, basically bumping out 2 flanges, but only bumps out the thickness of your sheet, so that one sheet can overlap another.

We have a list of useful metal roof accessories that can help in your next project. . Exposed Fastener Lap Seam Accessories. Closures; Underlayment; Door Track; Fasteners; Insulation; . Versa Vent. Download (5 mb) Closure Foam Info Sheet. Download (751 kb) Glued Closure MSDS Sheet. Download (139 kb) Vented Closure MSDS Sheet. Download (154 . What Is a Lap Seam Weld? In lap seam welding, two slightly overlapping metal sheets are joined by continuous local fusion. The welding process uses two wheel-shaped electrodes to apply pressure and pass electricity through the metal workpieces. Holding two metal parts together creates contact electrical resistance that causes heat energy to .Variety of Seams 1. Single Hem 2. Double Hem 3. Single Flange 4. Lap Seam 5. Outside Lap Seam 6. Plain Lap Seam. Double Flange; Single Flange; Double Seam; Groove Seam; Standing Seam; Wired Edge; Pittsburgh Seam The Pittsburgh is commonly used in sheet metal shops. The seams has two parts: 1. A single, 90 degree lock 2.Study with Quizlet and memorise flashcards containing terms like true or false, a double hymn requires two folding operations?, true or false, the width of the bend is limited in a bar folder?, allowance for metal thickness is not required when making seams of what gauge or lighter on a bar folder? and others.

Edward J. Laperouse Metal Works, Inc. offers quality commercial roofing and construction solutions that offer longer life and greater value for our customers. . The project included everything from a new artificial play surface to interior repairs to an 84,000 sq. ft. standing seam metal roof over an existing metal roof. Every aspect of the . 11. LAP SEAMS Lap seams can be joined by drilling and riveting, by soldering, or by both riveting and soldering. To figure the allowance for a lap seam, you must first know the diameter of the rivet that you plan to use. The center of the rivet must be set in from the edge a distance of 2 1/2 times its diameter; therefore, the allowance must be five times the diameter of . Study with Quizlet and memorize flashcards containing terms like Lap seam, Hook seam, Standing seam and more. Scheduled maintenance: June 29, 2024 from 04:00 PM to 05:00 PM. . the reinforcement cap made of sheet . This video discusses the different commonly used connection joints found on Sheet Metal Duct work.

Where is the offset lap seam used? and more. . Lap and lock seams: 9. What is the formula for determining a standing seam allowance on 16-gauge sheet metal? 3H + 2T or, three times the height of the seam plus twice the thickness of the material. 009. Lap and lock seams: 10. When joining two sheet metal duct sections with a standing seam, to . A standing seam roof uses a formed sheet metal joint with factory-applied sealant at the side lap joints, and sealant and exposed fasteners at the end lap joints. When doing a visual check of the roof system, some potential problem areas should be investigated first.

WESTERN LOCK® STANDING SEAM METAL ROOFING Panel End Lap Detail. We don't recommend using a panel end lap on a standing seam panel. It's a difficult installation and it could leak. It's best to use one long sheet. We have a maximum of 52' long sheet lengths when the panels are made at the factory.Formed edges are formed from the sheet metal itself.* Yes, true. Lap seams are commonly used for roof flashing and gutters.* Yes, true. A Pittsburgh lock is a true lock because it has a 1/4" tail.* Yes, true. A lap seam can be spot-welded.* Lap joints are commonly used to join two pieces of metal with differing thicknesses.Here are the welding styles for lap joints: Bevel-groove weld; J-groove weld; Flanged lap joint; Flare-bevel-groove weld; Slot weld; Spot weld; Fillet weld; Seam weld; Lap joints are often used in sheet metal applications, such as ductwork, frames, and other .Freund Tinman’s PVC Sheet Metal Mallets come in a variety of shapes and sizes and are perfect for old-world sheet metal crafting. . Seam Opening Pliers. Lap-on joint, precoated handles. Jaw width 1 1/8" 0.99lb length 9 7/8" .00. Add to cart. Quick view More info. ESE 001-625 First Stage Hand Seamer.

Sheet Metal // Ham // Seam // Notch // Grooved Seam // Lap Joint // 💥 #Operation_of_Sheet_MetalITI TECHNICAL ZONE प्रिय .

types of sheet metal seams

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Our exposed fastener metal panels offer an ideal roof and/or wall application for commercial, industrial, and architectural buildings. Code Compliance UL Ev . Call us Toll Free at 1-800-574-1388

Sealing metal roof seams . Can I lift up the lip of the seam and basically glue the top and bottom lap together with silicon underneath the roof for an invisible seal? . point it looks as tho they didn’t line up the top and bottoms very well either which is paramount when there is a 3 sheet intersection crossover. We like to double screw .Welding sheet metal parts. Christopher Dawes CEng, in Laser Welding, 1992. Lap seam joint. The lap seam joint is the most common laser welded sheet metal joint because it offers the most versatility from a design standpoint in respect of ease of manufacture under production conditions.

durham college precision metal fabrication

Here's the definitive answer: 1992-1993. "Alas, this small pleasure is about to end. By the end of the year, Johnson & Johnson will phase out the strings on all its Band-Aid products; some, like the Sesame Street and Glow-in-the Dark varieties, have already been changed.

lap seam sheet metal|sheet metal seams pdf