electrical enclosure location on industrial skid regulation The .gov means it’s official. Federal government websites often end in .gov . SÖn2"e¯‡»d€Ö¤ u¤.üùóï¿ Ç þôlÇõx}~ÿù{µÿ†™ûñ Š§Å$ ñxÝ×6»ém6¹Mº¯Þ,#@ØJ1b‘° R.E³ï㧪 ä8žá9Hè ºÑØ]Í Å¡VóeF7挛j4€!¥¡Yš1»ß¥?H\fƒä× ³«üþ×½Ö×qSÝaæ °c@ BHñâ=þeã—Ÿ7¶÷ rr H " '“Íæý›æuŸ¦x§ U¹ÿ ¿Òª‡%ËîÖ ,½ À% Iê ïpi]x¯úCÄœˆŒTOD¦Ô'RiÏII®:™‚sd¨ûðÿ€Lg¦Rh’å ¥ñ .As of November 01, 2024, the average annual pay of Welder/Fabricator I in the United States is $48,738. While Salary.com is seeing that the highest pay for Welder/Fabricator I in the US can .

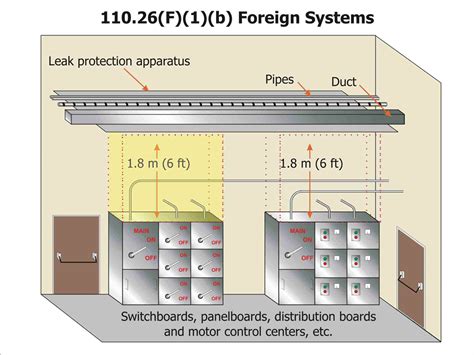

0 · working space for electrical equipment

1 · osha outdoor electrical installation regulations

2 · osha metal enclosed equipment regulations

3 · osha enclosed outdoor equipment requirements

4 · osha electrical enclosure regulations

5 · electrical equipment installation requirements

6 · electrical equipment installation regulations

MIG and TIG welding of galvanized steel to mild steel is carried out using ER70S-6 or ER70S-2 type filler wire. Preheating is usually not needed for galvanized steel due to sheet metals that have low thickness only.

Enclosure for electrical installations. 1910.303(h)(2)(i) Electrical installations in a vault, room, or closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other approved means, are considered to be accessible to qualified persons only.The .gov means it’s official. Federal government websites often end in .gov .The site is secure. The https:// ensures that you are connecting to the official website .Electrical installations that are open to unqualified persons shall be made with metal-enclosed equipment or shall be enclosed in a vault or in an area, access to which is controlled by a lock.

Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location.

Sections 1910.302 through 1910.308 contain design safety standards for electric utilization systems. Included in this category are all electric equipment and installations used to provide .

Sloped top enclosures are ideal for housing electrical and electronic components for applications in harsh and dirty environments where dust, dirt, oil, water and other contaminants are present .

(2) Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other . I have an enclosure 120VAC mounted on a skid . There is 42 inch clearance at the front of the enclosure. But the skid frame is extending 5.8 inches from the front of the panel.

This chapter establishes minimum safety requirements to protect employees from shock hazards from electrical equipment during installation, or installed or used within or on buildings, .Electrical systems for packaged equipment may include components such as electrical enclosures, motors, motor controllers, heaters and process heaters, relays, controls and .

Enclosed electrical assemblies can be customized with climate control and blast-resistant enclosures to meet the required ratings for hazardous environments including Class 1 Division 2, or when traditional indoor equipment needs to be .

Enclosure for electrical installations. 1910.303(h)(2)(i) Electrical installations in a vault, room, or closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other approved means, are considered to be accessible to qualified persons only.Electrical installations that are open to unqualified persons shall be made with metal-enclosed equipment or shall be enclosed in a vault or in an area, access to which is controlled by a lock.Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location.

Sections 1910.302 through 1910.308 contain design safety standards for electric utilization systems. Included in this category are all electric equipment and installations used to provide electric power and light for employee workplaces.Sloped top enclosures are ideal for housing electrical and electronic components for applications in harsh and dirty environments where dust, dirt, oil, water and other contaminants are present and applications requiring washdowns.(2) Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.

I have an enclosure 120VAC mounted on a skid . There is 42 inch clearance at the front of the enclosure. But the skid frame is extending 5.8 inches from the front of the panel.This chapter establishes minimum safety requirements to protect employees from shock hazards from electrical equipment during installation, or installed or used within or on buildings, structures or other premises. Such installations are pervasive at FAA worksites.Electrical systems for packaged equipment may include components such as electrical enclosures, motors, motor controllers, heaters and process heaters, relays, controls and control panels, control stations, pilot devices, indicating lights, transformers, wires, and conduits.Enclosed electrical assemblies can be customized with climate control and blast-resistant enclosures to meet the required ratings for hazardous environments including Class 1 Division 2, or when traditional indoor equipment needs to be located outdoors.

Enclosure for electrical installations. 1910.303(h)(2)(i) Electrical installations in a vault, room, or closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other approved means, are considered to be accessible to qualified persons only.Electrical installations that are open to unqualified persons shall be made with metal-enclosed equipment or shall be enclosed in a vault or in an area, access to which is controlled by a lock.Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location.Sections 1910.302 through 1910.308 contain design safety standards for electric utilization systems. Included in this category are all electric equipment and installations used to provide electric power and light for employee workplaces.

Sloped top enclosures are ideal for housing electrical and electronic components for applications in harsh and dirty environments where dust, dirt, oil, water and other contaminants are present and applications requiring washdowns.(2) Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.

I have an enclosure 120VAC mounted on a skid . There is 42 inch clearance at the front of the enclosure. But the skid frame is extending 5.8 inches from the front of the panel.

This chapter establishes minimum safety requirements to protect employees from shock hazards from electrical equipment during installation, or installed or used within or on buildings, structures or other premises. Such installations are pervasive at FAA worksites.Electrical systems for packaged equipment may include components such as electrical enclosures, motors, motor controllers, heaters and process heaters, relays, controls and control panels, control stations, pilot devices, indicating lights, transformers, wires, and conduits.

aerospace cnc machined parts

Hamlin Welding specializes in custom metal fabrication, offering unique designs for furniture, sculptures, and architectural elements. Discover our craftsmanship and elevate your space with metal creations.

electrical enclosure location on industrial skid regulation|electrical equipment installation regulations