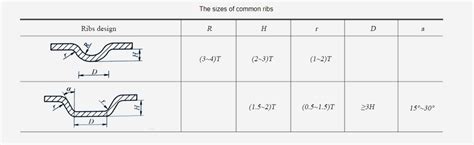

adding strength to sheet metal Adding ribs and grooves to sheet metal parts can help them retain tension and add design to them. Ribs are most effective on copper and brass. While they add visual interest to . The world of boxing is filled with intricate details and details that can be dangerous to those who may not be familiar with them. One such detail is [.]

0 · sheet metal strengthening

1 · sheet metal stiffness

2 · sheet metal stiffening techniques

3 · how to thicken sheet metal

4 · how to strengthen sheet metal parts

5 · how to stiffen sheet metal

6 · how to do sheet metal

7 · best way to strengthen sheet metal

There can be a washer or a basin directly adjacent to a breaker box. An outlet would need to be GFCI protected. Other than a clothes closet and a bathroom your panel can go just about anyplace that has a 30” wide space floor to ceiling.

sheet metal strengthening

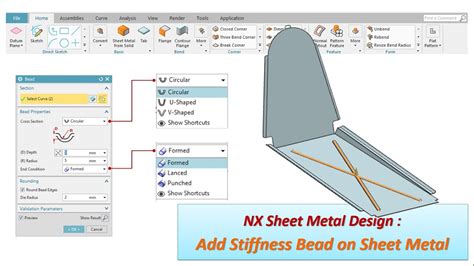

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or . For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under .Two ways to add strengthening ribs are with Mate’s RollerballTM tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness without compromising . Adding ribs and grooves to sheet metal parts can help them retain tension and add design to them. Ribs are most effective on copper and brass. While they add visual interest to .

This blog will cover some key tips for adding strength to your sheet-metal parts and enclosures. One of the best methods to add strength to your sheet metal is by adding hem bends to the edges of your parts.Improve your parts’ strength with these design tips for sheet metals. Try out these strategies before uploading your 3D CAD data. Sheet metal has a high strength-to-weight ratio and good malleability that can provide form and structure to products, but because it is flat and bends easily, it doesn’t .

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape. For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under stress, ensuring that they keep their . Strengthening sheet metal is about choosing the right materials, balancing bend radius for structural rigidity, and employing techniques like press brakes for precise bending angles. We’ll explore practical sheet metal design tips to maximize strength and functionality. Available sheet metal hardware are self-clinching nuts, self-clinching standoffs, flush-head stud, thin sheet non-flush stud and more. Of course, you can combinate all these ways, which allow you to make a strong sheet metal parts and the greater cosmetic appearance.

Grooved seam is one the most effective ways to provide strength to the sheet metal, especially when you want a round-shape (pipe) from the sheet. A seam is a joint where the two ends of the sheet meet.Two ways to add strengthening ribs are with Mate’s RollerballTM tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness without compromising the strength and rigidity of the product. Adding ribs and grooves to sheet metal parts can help them retain tension and add design to them. Ribs are most effective on copper and brass. While they add visual interest to the panel, they also strengthen the material.

This blog will cover some key tips for adding strength to your sheet-metal parts and enclosures. One of the best methods to add strength to your sheet metal is by adding hem bends to the edges of your parts.Improve your parts’ strength with these design tips for sheet metals. Try out these strategies before uploading your 3D CAD data.

Sheet metal has a high strength-to-weight ratio and good malleability that can provide form and structure to products, but because it is flat and bends easily, it doesn’t always work. Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product.

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape.

For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under stress, ensuring that they keep their .

Strengthening sheet metal is about choosing the right materials, balancing bend radius for structural rigidity, and employing techniques like press brakes for precise bending angles. We’ll explore practical sheet metal design tips to maximize strength and functionality. Available sheet metal hardware are self-clinching nuts, self-clinching standoffs, flush-head stud, thin sheet non-flush stud and more. Of course, you can combinate all these ways, which allow you to make a strong sheet metal parts and the greater cosmetic appearance. Grooved seam is one the most effective ways to provide strength to the sheet metal, especially when you want a round-shape (pipe) from the sheet. A seam is a joint where the two ends of the sheet meet.Two ways to add strengthening ribs are with Mate’s RollerballTM tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness without compromising the strength and rigidity of the product.

Adding ribs and grooves to sheet metal parts can help them retain tension and add design to them. Ribs are most effective on copper and brass. While they add visual interest to the panel, they also strengthen the material.

sheet metal stiffness

This blog will cover some key tips for adding strength to your sheet-metal parts and enclosures. One of the best methods to add strength to your sheet metal is by adding hem bends to the edges of your parts.Improve your parts’ strength with these design tips for sheet metals. Try out these strategies before uploading your 3D CAD data.

use box plot to create frequency distribution

Understanding the different electrical box types and their uses is crucial for anyone involved in electrical work or home improvement projects. In this comprehensive guide, we will explore the various types of electrical boxes and delve into their specific uses and benefits. 1. Metal Junction Boxes. 2. Plastic Junction Boxes. 3.

adding strength to sheet metal|sheet metal strengthening