cnc forged part CNC machining options include turning, boring, facing, and drilling. The video . $3.02

0 · what is forging

1 · forging vs cnc

2 · custom forged metal parts

3 · custom forged metal ends

Aluminum signage utilizes waterjets and lasers to precisely cut the lettering and numbers providing greater detail than routers. These beautiful metal letters have clean, crisp edges and .

Get custom-forged metal, crafted by industry-leading open die forging techniques. From stainless steel forging to CNC milling, we can produce your custom parts.

Forged flats provide superior mechanical qualities over standard plate or rolled .CNC machining options include turning, boring, facing, and drilling. The video .Forged Flats Custom Forged Rounds, Discs & Sleeves Forged Hubs, Spindles & .With over six decades of experience, we have the knowledge and expertise to .

The blocks themselves are not a finished product; instead, they are used by .

what is forging

forging vs cnc

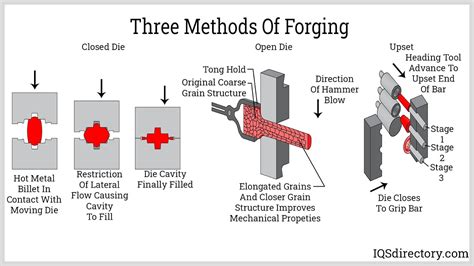

Individually forged rounds and discs with a 3 to 1 minimum reduction can .Our forged part options include blocks, rectangles, flats, rounds, discs, hubs, . When manufacturing high-quality components, two of the most commonly used processes are forging and CNC machining. Each of the methods has its benefits and it is up to you to decide which of the methods will be used .Forging is primarily concerned with the shaping of solid metal parts via drop or upset forging, for example, and is designed to maximize the integrity and durability of the part by preserving and .

Surface finishes on a CNC machined part will typically be near perfect and appear very consistent and precise, whereas cast or forged parts will be a little rougher, usually . Our commitment to precision and customer satisfaction allows us to deliver high-quality, well-priced products on schedule. Once forged, components can be post-processed by precision CNC machining and surface .Improve your application’s performance with steel forged products from Marberry Machine. As a leading large forging parts manufacturer, we produce rough, semi-finished, and finished parts .

In the telecommunications industry, CNC machined parts play a pivotal role in the manufacturing of antennas and communication devices. The intricate details achievable through machining ensure that these components meet the high . Machining, unlike forging, is a subtractive manufacturing process. The final part is created in machining by removing excess material from a workpiece. This is typically done .

custom forged metal parts

In summary, CNC machining is a subtractive process that offers high design flexibility and precise machining capabilities for a variety of plastics or materials. Conversely, forging is a formative .The CNC Machines remove excess material with accuracy. From aircraft landing gear that withstands punishing takeoffs and landings to medical implants that require unwavering strength and biocompatibility, machined forgings are the .

Get custom-forged metal, crafted by industry-leading open die forging techniques. From stainless steel forging to CNC milling, we can produce your custom parts. When manufacturing high-quality components, two of the most commonly used processes are forging and CNC machining. Each of the methods has its benefits and it is up to you to decide which of the methods will be used in a particular project as per your distinctive requirements and needs.Forging is primarily concerned with the shaping of solid metal parts via drop or upset forging, for example, and is designed to maximize the integrity and durability of the part by preserving and refining the grain structures. Forged parts are therefore ideal for high-stress applications. Surface finishes on a CNC machined part will typically be near perfect and appear very consistent and precise, whereas cast or forged parts will be a little rougher, usually requiring polishing or tumbling in an abrasive media to achieve a better surface finish.

pay of gun manufacturers for cnc

Our commitment to precision and customer satisfaction allows us to deliver high-quality, well-priced products on schedule. Once forged, components can be post-processed by precision CNC machining and surface finishing.Improve your application’s performance with steel forged products from Marberry Machine. As a leading large forging parts manufacturer, we produce rough, semi-finished, and finished parts and fabricated assemblies for demanding applications.In the telecommunications industry, CNC machined parts play a pivotal role in the manufacturing of antennas and communication devices. The intricate details achievable through machining ensure that these components meet the high standards required for seamless communication. Machining, unlike forging, is a subtractive manufacturing process. The final part is created in machining by removing excess material from a workpiece. This is typically done using CNC (Computer Numerical Control) machines that operate with high precision and automation.

In summary, CNC machining is a subtractive process that offers high design flexibility and precise machining capabilities for a variety of plastics or materials. Conversely, forging is a formative process that enhances the strength and durability of metals, making it suitable for producing high-strength components.The CNC Machines remove excess material with accuracy. From aircraft landing gear that withstands punishing takeoffs and landings to medical implants that require unwavering strength and biocompatibility, machined forgings are the engineering and .Get custom-forged metal, crafted by industry-leading open die forging techniques. From stainless steel forging to CNC milling, we can produce your custom parts.

When manufacturing high-quality components, two of the most commonly used processes are forging and CNC machining. Each of the methods has its benefits and it is up to you to decide which of the methods will be used in a particular project as per your distinctive requirements and needs.Forging is primarily concerned with the shaping of solid metal parts via drop or upset forging, for example, and is designed to maximize the integrity and durability of the part by preserving and refining the grain structures. Forged parts are therefore ideal for high-stress applications.

Surface finishes on a CNC machined part will typically be near perfect and appear very consistent and precise, whereas cast or forged parts will be a little rougher, usually requiring polishing or tumbling in an abrasive media to achieve a better surface finish.Our commitment to precision and customer satisfaction allows us to deliver high-quality, well-priced products on schedule. Once forged, components can be post-processed by precision CNC machining and surface finishing.Improve your application’s performance with steel forged products from Marberry Machine. As a leading large forging parts manufacturer, we produce rough, semi-finished, and finished parts and fabricated assemblies for demanding applications.In the telecommunications industry, CNC machined parts play a pivotal role in the manufacturing of antennas and communication devices. The intricate details achievable through machining ensure that these components meet the high standards required for seamless communication.

Machining, unlike forging, is a subtractive manufacturing process. The final part is created in machining by removing excess material from a workpiece. This is typically done using CNC (Computer Numerical Control) machines that operate with high precision and automation.In summary, CNC machining is a subtractive process that offers high design flexibility and precise machining capabilities for a variety of plastics or materials. Conversely, forging is a formative process that enhances the strength and durability of metals, making it suitable for producing high-strength components.

custom forged metal ends

We can supply stampings in virtually every type of materials. We handle a wide range of secondary or finishing options to your stamped piece. Exceeding your expectations at every turn, by continuously improving customer satisfaction, .

cnc forged part|what is forging