316 stainless steel cnc machining 316 stainless steel is commonly used in CNC machining due to its excellent strength, high corrosion resistance and excellent machinability, making it suitable for a variety of industrial applications. Join multiple load cells to combine their weight measurements. Choose from our selection of electrical enclosures, including indoor enclosures, oil-resistant enclosures, and more. In stock and ready to ship.

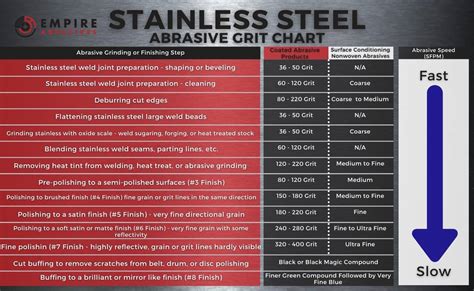

0 · surface grinding 316 stainless steel

1 · stainless steel machinability chart

2 · stainless steel 316 composition chart

3 · 316 stainless steel thickness chart

4 · 316 stainless steel size chart

5 · 316 stainless steel equivalent grades

6 · 316 stainless steel data sheet

7 · 304 vs 316 machinability

$31.97

316 stainless steel is commonly used in CNC machining due to its excellent strength, high corrosion resistance and excellent machinability, making it suitable for a variety of industrial applications.Machining Stainless Steel 316. Stainless Steel 316 is an austenitic stainless steel alloy with 17% chromium and 13% nickel. It is the most popular stainless steel when high corrosion resistance is required. It is a chromium-nickel .

316 stainless steel is commonly used in CNC machining due to its excellent strength, high corrosion resistance and excellent machinability, making it suitable for a variety of industrial applications.

Machining Stainless Steel 316. Stainless Steel 316 is an austenitic stainless steel alloy with 17% chromium and 13% nickel. It is the most popular stainless steel when high corrosion resistance is required. It is a chromium-nickel-molybdenum stainless with low carbon (0.08%) content. CNC machining creates intricate and precise stainless steel components through computerized automation. This article will delve into the different grades of stainless steel available, covering their advantages and applications. You'll also learn how to overcome various challenges associated with CNC machining of stainless steel material. In summary, CNC machining of 316 stainless steel offers advantages such as corrosion resistance, high-temperature suitability, and strength. However, one must carefully manage challenges related to machinability, tool wear, heat generation, and post-machining.

Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information.

With a tensile strength of up to 579 MPa (84 ksi) and a yield strength of up to 290 MPa (42 ksi), Stainless Steel 316 can withstand high levels of stress and deformation without losing its shape or structural integrity.

Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running parameters, headaches from milling steel can become a thing of the past.Stainless steel 316/316L has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications. • Food preparation equipment particularly in chloride environments. • Laboratory benches & equipment. • Coastal architectural panelling, railings & trim. • Chemical containers, including for transport.

Continental Manufacturing offers industry-leading CNC machining for 316 stainless steel. Request a quote today to find out more about our alloy 316 machining services!Stainless steel 316L (CNC) has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications. 20% off your first order.316 stainless steel is commonly used in CNC machining due to its excellent strength, high corrosion resistance and excellent machinability, making it suitable for a variety of industrial applications.Machining Stainless Steel 316. Stainless Steel 316 is an austenitic stainless steel alloy with 17% chromium and 13% nickel. It is the most popular stainless steel when high corrosion resistance is required. It is a chromium-nickel-molybdenum stainless with low carbon (0.08%) content.

surface grinding 316 stainless steel

CNC machining creates intricate and precise stainless steel components through computerized automation. This article will delve into the different grades of stainless steel available, covering their advantages and applications. You'll also learn how to overcome various challenges associated with CNC machining of stainless steel material.

stainless steel machinability chart

In summary, CNC machining of 316 stainless steel offers advantages such as corrosion resistance, high-temperature suitability, and strength. However, one must carefully manage challenges related to machinability, tool wear, heat generation, and post-machining.Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information.With a tensile strength of up to 579 MPa (84 ksi) and a yield strength of up to 290 MPa (42 ksi), Stainless Steel 316 can withstand high levels of stress and deformation without losing its shape or structural integrity. Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running parameters, headaches from milling steel can become a thing of the past.

Stainless steel 316/316L has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications. • Food preparation equipment particularly in chloride environments. • Laboratory benches & equipment. • Coastal architectural panelling, railings & trim. • Chemical containers, including for transport.

Continental Manufacturing offers industry-leading CNC machining for 316 stainless steel. Request a quote today to find out more about our alloy 316 machining services!

stainless steel cabinet pulls and hinges

stainless steel cabinet shelf

stainless steel 316 composition chart

Get the best deals on White House Black Market Women's Striped Sweaters for Women when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

316 stainless steel cnc machining|316 stainless steel equivalent grades