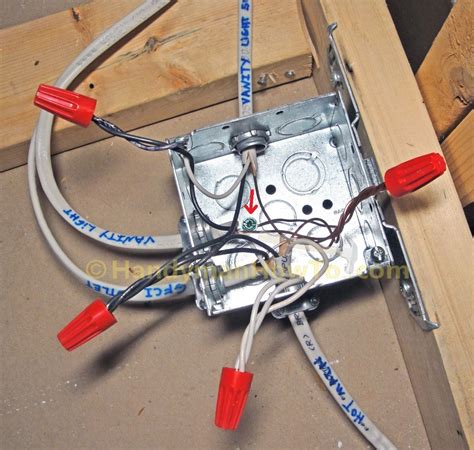

how to secure wires in a junction box Secure cables to the junction box using clamps or connectors. Connect circuit cables inside the junction box with proper insulation and security. Follow NEC guidelines for .

Slant bed CNC Lathe. Compared with the flat bed CNC lathe, the slant bed design has better chip removal ability. The independent tailstock and steady rest slide ways provide more variable long-parts processing capabilities, and the automatic loading and unloading system can be integrated to provide better production volume.

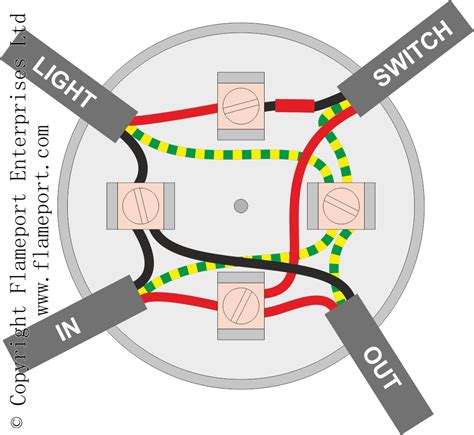

0 · wiring junction box for lighting

1 · wire a junction box diagram

2 · junction box wiring guidelines

3 · junction box installation instructions

4 · junction box for electrical wiring

5 · electrical junction box instructions

6 · connecting wires in junction box

7 · 3 terminal junction box wiring

Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision aluminum machining services. Our aluminum machining capabilities enable us to machine aluminum parts with tight tolerances and complex geometries, making us the go-to partner for various industries.

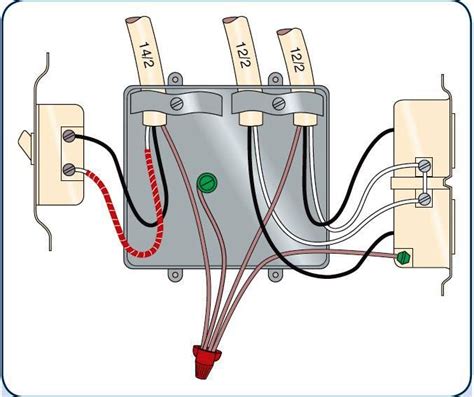

How To Wire Junction Boxes. ElectricianToolDeals. 4K subscribers. Subscribed. 36. Share. 8.1K views 1 year ago. Nothing is more dangerous and aggravating than loose wires in a. One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing . When connecting wires within a junction box, it’s crucial to ensure that the connections are secure and reliable to maintain the integrity and safety of the electrical system. Several methods can be employed to achieve this, each . What you need to do is apply a paintable silicone acrylic or silicone caulk to the back of the box and around the entry hole before you screw the box to the wall. There should be holes inside the box or external ears for mounting.

Installing a junction box is an important step in electrical wiring projects. It provides a safe and secure enclosure for electrical connections, helps to prevent electrical fires, and allows for easy access to wiring for maintenance or . Secure cables to the junction box using clamps or connectors. Connect circuit cables inside the junction box with proper insulation and security. Follow NEC guidelines for .

Nonmetallic, or NM, cable (commonly known by the brand name Romex) must be secured to electrical boxes at the point where the cable enters the box. This code requirement is an important safety feature that protects the . A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.NM-cables must be securely fastened where they enter an electric panel, so that tugging on a cable from outside the box will not pull wires loose from their terminations inside. This is . Junction Box Size. Junction boxes are sized according to how many wires they can hold—because, among other things, an overstuffed junction box is a fire hazard. The National Electrical Code has published a chart that .

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se. This code requirement is an important safety feature that protects the wiring connections inside the box in case the cable is pulled. It also prevents the cable from rubbing against the edge of the box and potentially damaging .Section 2: Step-by-Step Instructions on Wiring an Electrical Junction Box. Wiring an electrical junction box can seem like a daunting task, but with the right instructions and proper precautions, it can be easily accomplished. In this section, we will provide you with step-by-step instructions on how to wire an electrical junction box. Use screws and faster the box to the (looks like wood so use some longer wood screws about 6) and fasten it tightly to the wall. Apply water repellent silicone to the outside permiter of the box after you fastened, use your finger to create a curved area- don't be shy , all around the box one with no breaks.

Mechanically fastening wires together before they enter the splice would help keep them together under extraordinarily violent vibration. But generally speaking, anything severe enough to knock regular old wire nuts loose inside a normal junction box is going to rip any house off its foundation and reduce it to splinters. Extreme overkill.

wiring junction box for lighting

wire a junction box diagram

Learn about junction box electrical wiring, including how to install and troubleshoot wiring connections in junction boxes for electrical circuits. Skip to content. WireBlueprint.com. . Insert the junction box into the hole and secure it in place using the provided mounting screws. Make sure the box is flush with the wall or ceiling surface. Follow the instructions provided in your light fixture assembly kit and use the nuts, bolts, and brackets to secure it to your junction box. Make sure that all of the screws are tightly secured and that the connections are properly aligned. . Never install any wiring, junction box, or light fixture while power is still on—this can result in .

That's as easy as a junction box inside with a short conduit nipple to outside and some THWN wires. . What you described is what I had planned. I had a question about how to mechanically secure the wire where it enters the back of a surface mounted box. That’s where I proposed using a water tight cable bushing.

Welcome to our Introduction to Electrical Wiring Series: In these process videos, we review the wiring process from installing a junction box to how to wire. When UL approves the box, they also approve the labeling on the box, and the instruction sheet intended to go with the box. Of course, big-box stores buy by the carton, sell them loose in bins, and don't give you the instruction sheet. But it should be on the Internet.Hi, I need help understanding the code/best practice for securing my wire run into a metal junction box that is being tied up to a power outlet. I am the home owner and the project location is an exposed ceiling run in my garage. I'm using 1/2" EMT and 1/2" Set Screw Connectors like in the image attached. Here are my two questions:

Wear appropriate safety gear, such as insulated gloves and safety goggles. Ensure the junction box is dry and free from any potential hazards. 3. Prepare the Junction Box. Open the junction box and ensure it’s clean and free from any debris or dust. Check that it’s the correct size for your wires and provides enough space for proper wire .Step 7: Secure the wires and close the junction box. Once the connections are tested and verified, neatly arrange the wires inside the junction box and secure them with cable clamps or clips. Then, close the junction box and tighten the screws to ensure a secure fit. I am installing some recessed lighting cans into a ceiling already drywalled with no access above the drywall. I am using the remodeling cans with the metal junction box attached to the can assembly. I will have two, 3-wire 12 gauge cables coming into the junction box for each light. This is the typical wiring with shielding I see in construction.

There are a few different ways to connect 6 gauge wire in a junction box. The most common way is to use terminal blocks. To do this, first strip about 1/2 inch of insulation off the end of the wire. . Finally, tighten the screw on the terminal block to secure the wire in place. Strip the insulation off of the end of the 6 gauge wire using . A junction box provides a secure enclosure and protects wiring connections. It is important to choose the right size and shape of the junction box to accommodate the number of wires involved. Following the guidelines of the National Electrical Code (NEC) is crucial for a . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Once the junction box is prepared and securely in place, you can proceed to the next step of stripping the wires. Step 3: Strip the Wires. With the junction box prepared, it’s time to strip the insulation from the ends of the electrical wires. Properly stripping the wires will allow for secure connections inside the shallow electrical box. Step 7: Secure the New Junction Box to the Wall or Ceiling. Securing the junction box to the wall or ceiling is an important step in replacing a junction box. Depending on the type of junction box you are using, you may need to hang it with a metal bar, screw it down with joists or use a flush mount with a drywall plate. I show how to use the carlon handy box to install a outlet no romex connector needed how to fold wires into a box keeping ground wire away from live and neut.Inside a junction box, electrical wires are connected together using wire nuts, terminal blocks, or other suitable connectors. These connections ensure a secure and reliable electrical circuit. Junction boxes are available in various sizes and materials, depending on the specific application and environment they will be used in.

Since no one else has mentioned it as an option yet, rather than drilling two additional holes in your joist, you could also add cut a small piece of wood that is narrow enough to sit between the two NM clamp screws to serve as a 3/4" (or more) riser and use two longer screws to secure the junction box (going through the junction box holes .

There's no NEC requirement that the end of an abandoned cable, energized or not, be inside a junction box. You can tape or wire nut it off and stuff it inside the wall, if you want to, and that's legal. One reason not to give DIY advice: Catch a man a fish and you can sell it to him.Mastering Junction Box Wiring Safety • Wiring Safety Tips • Learn how to securely and safely organize wires in a plastic junction box with expert tips on str. The previous extractor fan used wire nuts in a metal-enclosed space similar to a junction box, . Using a quick connector, secure 120 VAC house wiring from the wall switch to the fan as shown in the wiring diagram on page 3. It is odd that this model doesn't provide an integrated box, but you're expected to provide one. .Kung Fu Maintenance shows how to replace loose wobbling ceiling fan wiring junction box repair. Nice Little Hand Held Drill .

junction box wiring guidelines

how to oxy acetylene weld sheet metal

By offering finished, assembled components and bespoke shipping, PHB can provide the integrated services required to be your complete global manufacturing resource. Looking to learn more about aluminum die-cast manufacturing and precision aluminum parts? Get .

how to secure wires in a junction box|junction box installation instructions