creo sheet metal box Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options specific to Solid include: • Cut replaces an existing bend edge by a cut edge and divides the selected part into two parts.

Under Kitchen Sink Junction Box Wiring Options. There are two ways to wire the branch circuit for the under kitchen sink electrical outlet: A) With a 4 inch square junction box in the sink cabinet, or B) Without a junction box. These wiring options are illustrated in the following wiring diagrams. Option A: 4 inch square junction box:

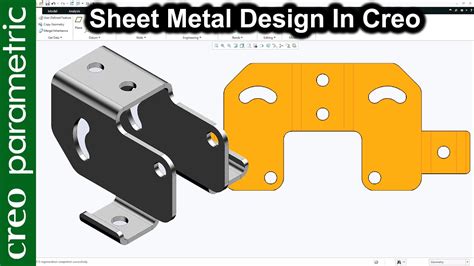

0 · sheet metal creo tutorial

1 · sheet metal creo parametric

2 · flat vs flange in creo

3 · creo sheet metal tutorial pdf

4 · creo sheet metal practice drawing

5 · creo sheet metal basics

6 · creo practice sheet metal models

7 · creo parametric sheet metal tutorial

A fábrica de esferas de aço é uma empresa que produz esferas de aço para aplicações como rolamentos de bicicletas, skates, válvulas de retenção, equipamentos de movimento para indústria, caixas de direção, bombas, .

This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell .Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options .This method of working with sheet metal is to create a solid first then shell it before .Creo Parametric comes with a feature called Sheet Metal. It is intended for .

Under Sub-type click Sheetmetal. 4. In the File Name box, type a name for your new sheet metal part. 5. If you want to use the default template, click OK. a. Clear Use default template and .

Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options specific to Solid include: • Cut replaces an existing bend edge by a cut edge and divides the selected part into two parts. This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from .

PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and . Creo Pro/ENGINEER Sheet Metal TutorialsThank You For Watching.My channelhttps://www.youtube.com/channel/UC_dcgiD5ntDQKXi8PSxVKew?sub_confirmation=1Creo .Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric .

sheet metal creo tutorial

Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc. . This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part.Under Sub-type click Sheetmetal. 4. In the File Name box, type a name for your new sheet metal part. 5. If you want to use the default template, click OK. a. Clear Use default template and click OK. The New File Options dialog box opens. b. Browse to the desired template. Click OK.

Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options specific to Solid include: • Cut replaces an existing bend edge by a cut edge and divides the selected part into two parts. This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from a number of flat pieces joined together. 1. Create and name a new Part 2. Extrude a 200x100 rectangle 50 mm to give a solid and Shell from the top surface to 2mm 3. PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and chamfers, and use additional options.

Creo Pro/ENGINEER Sheet Metal TutorialsThank You For Watching.My channelhttps://www.youtube.com/channel/UC_dcgiD5ntDQKXi8PSxVKew?sub_confirmation=1Creo Tutor.

Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric and serves as the second stage of learning.

Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc. However, Sheet Metal is ideal for the design of nets for . The sheet metal mode in Creo is a specialized environment that allows you to work exclusively on sheet metal components. It transforms your CAD software into a dedicated tool for designing and editing sheet metal parts.

electrical ceiling light box

This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part.Under Sub-type click Sheetmetal. 4. In the File Name box, type a name for your new sheet metal part. 5. If you want to use the default template, click OK. a. Clear Use default template and click OK. The New File Options dialog box opens. b. Browse to the desired template. Click OK.Creo Elements/Direct Sheet Metal creates a new 3D sheet metal part. Options specific to Solid include: • Cut replaces an existing bend edge by a cut edge and divides the selected part into two parts.

electrical breaker panel box

This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from a number of flat pieces joined together. 1. Create and name a new Part 2. Extrude a 200x100 rectangle 50 mm to give a solid and Shell from the top surface to 2mm 3. PTC Creo Parametric 9.0 Basic Sheet Metal Tutorial For Beginner. This tutorial is designed for beginners who have basic knowledge of PTC Creo Parametric 9.0..Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and chamfers, and use additional options.

Creo Pro/ENGINEER Sheet Metal TutorialsThank You For Watching.My channelhttps://www.youtube.com/channel/UC_dcgiD5ntDQKXi8PSxVKew?sub_confirmation=1Creo Tutor.Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric and serves as the second stage of learning.Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc. However, Sheet Metal is ideal for the design of nets for .

sheet metal creo parametric

flat vs flange in creo

Cover for Underground Enclosure, R Series, 10 x 15 x 1-3/4 Inch, Legend: ELECTRIC, Skid Resistant, Rated Light Duty/Pedestrian Traffic, Composite With UV Inhibitor

creo sheet metal box|flat vs flange in creo