bending sheet metal forming Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Classic look of 32 gauge, galvanized corrugated panels. Perfect for roof and wall applications with a variety of uses, minimum recommended roof slope of 3:12. Resistant to mildew, rot and pests and virtually maintenance free. Environmentally responsible choice containing a up to 30% recycled content and is 100% recyclable

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Browse the leading marketplace of used CNC machines for sale. Our frequently updated inventory offers over 100 brands, including Haas, Mazak & Makino. Machinery Network

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . One of the most commonly utilized sheet metal forming processes at Xometry is bending. Bending sheet metal requires the use of specialized but fairly simple bending tools, like press brakes. The sheet metal bending . Have you ever wondered how to achieve perfect sheet metal bends? This article dives into essential bending techniques, exploring everything from calculating material expansion to selecting the right tools. You’ll learn . Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .

We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE " Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

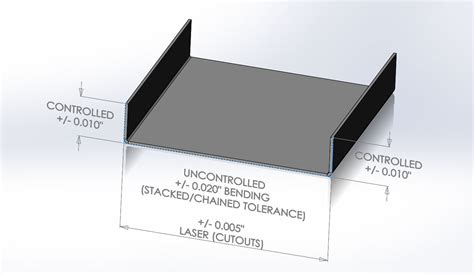

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius bending. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

One of the most commonly utilized sheet metal forming processes at Xometry is bending. Bending sheet metal requires the use of specialized but fairly simple bending tools, like press brakes. The sheet metal bending process is quick, accurate, and . Have you ever wondered how to achieve perfect sheet metal bends? This article dives into essential bending techniques, exploring everything from calculating material expansion to selecting the right tools. You’ll learn how to tackle common challenges, ensuring high-quality, efficient production. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE " Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius bending. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. One of the most commonly utilized sheet metal forming processes at Xometry is bending. Bending sheet metal requires the use of specialized but fairly simple bending tools, like press brakes. The sheet metal bending process is quick, accurate, and .

Have you ever wondered how to achieve perfect sheet metal bends? This article dives into essential bending techniques, exploring everything from calculating material expansion to selecting the right tools. You’ll learn how to tackle common challenges, ensuring high-quality, efficient production. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

types of bending sheet metal

silver sheet metal augusta ga

Browse our selection of used metal storage containers for sale to find the right storage solution for your manufacturing facility. These tubs and bins are used to ship and store raw industrial materials, including metal pipes, rods and mechanical .

bending sheet metal forming|sheet metal bending near me