how to register part on cnc router It might seem simple, to add dowel pins for registration on your CNC, but you must understand how the offsets work to ensure that your registration aligns perfectly for every job you run. ACVW Split Window Bus Floor Pans, Floor Supports, Heater Channels, Rocker Panels

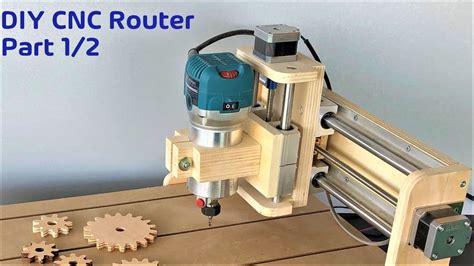

0 · how to make a cnc router

1 · cnc router top clamping

2 · cnc router hold material in place

3 · cnc router hold in place

4 · cnc router fastening

Junction Box Assembly for Walk In Cooler and Freezer Lights; Junction Box Assembly Complete with Lamp Housing. Base Fixture for VXS lights.

It might seem simple, to add dowel pins for registration on your CNC, but you must understand how the offsets work to ensure that your registration aligns perfectly for every job you run. Do you have registration pins, bars, or something else to make sure your 0 point is always in the same place? I plan to make some fixtures and am looking for the best way to .

Onion skinning, leaving a paper-thin bit of material at the bottom of a profile cut, is a great way to keep small parts secure on a CNC router. What follows are some of the best conditions in which to cut small parts, along with alternative methods if your setup doesn’t quite fit the bill. How to set up your CNC router. When. In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid. I use VCarve . However, by rule of thumb, any part smaller than the palm of your hand should be considered ‘small’. This blog discusses the best conditions in which to cut small parts, and .

Try these simple remedies. Keep the movement of small parts to a minimum with the following tips: Either take a skim cut off the sacrificial bed or replace it altogether. You want to direct your vacuum on the small part, so close any .

With All Star CNC Gasket you can cut parts cleaner, quicker, and without tabs or onion skinning. The key is turning you basic CNC Router Downdraft Vacuum system into a CNC Router Vacuum. Your CNC router offers many different joinery options, from exposed and visceral to clean and concealed. Consider how you can combine tools such as a handheld router to open up new possibilities. There are many .

I needed a way to hold small parts to my CNC that didn't involve tape, screws, or clamps. So I used the HUGE vacuum table on my CNC to hold small parts.Link.

This blog discusses the best conditions in which to cut small parts, and provides alternative methods if your setup doesn’t quite fit the bill. How to set up your CNC router. When processing small parts there will inevitably be very little vacuum hold. This may particularly be a problem at the end of the cut cycle as the part is likely to move.

Have a question about our products or capabilities? We are happy to answer any questions you have and guide you through the process of deciding what you need. Over the years, however, routers have become more accurate and capable and are used more and more to machine parts that were once machined on CNC milling machines. The larger machine table sizes of today’s routers, coupled with the high speed spindles, makes them an ideal choice for machining thin and small parts from sheet or plate material.

Zero the Z axis on your CNC router following the procedure provided here. Make sure the spindle or router is turned off. Use spray adhesive on the back of the sign and adhere the sign to your drag knife spoilboard. Zero the X and Y axes. Spray adhesive works better than masking tape for this thin plastic. Run the stencil toolpath.Head for Your CNC . A 1/8” spiral upcut spiral bit works great for small, detailed work like these Christmas trees. Mount your material on the CNC. Zero the X, Y and Z axes. Run the toolpath. A successful onion skin toolpath. Setting the Parts Free . You have a few options for releasing the parts from the main board.

I have had to split this video into two parts due to its length and this is the second part. It is important to understand the basics of router template work. CNC router preventative maintenance is one of the most overlooked ways to keep CNC routers online and productive. Using this CNC router maintenance guide in your factory can reduce the overall cost of machine ownership. Preventative maintenance will ensure maximum return on CNC routers, while keeping the headaches down and production quality up.

Go to your CNC router, place the stock you want to engrave and secure it to the cutting bed. Drill the locating holes and engrave your design on one side. I used an 1/8 end mill for drilling - it's easier to find the centre of a smaller hole. Step 3: Flip . Table setups for CNC routers vary so much depending on projects but hopefully we can help others in getting the best setup for theirs. . As David points out if you use the same start point all the time then the parts of your CNC at that location will wear faster than the rest of the machine. Having multiple registration locations for certain .Hello, in this video I'll show you how to prepare files for CNC router using Fusion 360.#CNC #fusion360 #cncmachineMusic: bensounds0:00 - 0:23 intro0:23 - 1:.

CNC Router Skills: Part One: All about Origin Points . CNC Router duplication has been around a long time. Early machines used stiluses to follow the shape of a pattern or master, while on the

Pulling the part up and off the fixture is not the main concern with a small part and vacuum. It's the side loading from tool pressure that is going to bite you first. My suggestion would be to make these out of large sheets. Machine all the holes in all the parts, then bolt the parts down through those holes and machine the profile.Did you know you can cut finger joints on your CNC router? Here’s what you need to know to make this joint. (800) 234-1976 . Once together there should be enough friction that the parts stay together if you’re holding on to only one piece. . Register / Login .

Loading and unloading parts on to a flat table CNC router without spending a bunch of money on a vacuum lift. We can literally roll sheets of melamine on to. In this video, Ryan shows you how to cut materials larger than your CNC Machine - this technique is going to help you get the most out of your WorkBee CNC Ma.

Half of people say you can't cut steel on a CNC router, and then other people post videos of them doing it. . The next concern is the quality of the part. The bigger the gantry the more possibility for flex and vibration. On the mill the machine’s . How to reset the VFD on a CNC Router if your spindle won't work. Reset instructions: http://www.soatmon.com/2020/10/how-to-reset-vfd-on-cnc-router.html6040 C. I have attempted to export some of the parts I designed in Shapr3d so I could convert to G-code and cut on my cnc (using Carveco Maker+). Every attempt is unsuccessful. If I try .stp or .stl it opens wonky. If I save as a .dxf, the drawing shows up in 2d. but not 3d. However, my project has almost 50 parts. I understand from the original zoom meeting that I can copy .

I do not see an easy way to take the elements of my 3D model of the birdhouse and explode them and orient them on the same plane in a way that would translate to the CNC? Model one logical part of the birdhouse. Stop and make that part a Group or Component. Then model the next logical part of the birdhouse. Stop and make that part a Group or . Just as the title says how do you register material on your CNC. I am referring to it's placement from X,Y,Z zero point. Do you just fix it to the tabl . DIY CNC Router Table Machines; How do you register material on your machine; . Then get close to the part and move the spindle in thousands of an inch until the bit touches the aluminum . 4 After cutting the parts, separate them from the waste, but leave the waste attached to your CNC spoilboard. If you need to take the waste part off your machine, drill some registration dowel holes through the waste and into the spoilboard so you can accurately place the waste back on your machine for the V-carving step later.

Your whole CNC router may be vibrating, leading to the chatter you have. It could be that you left your leveling screws loose, or maybe you did the same with other components on your CNC router. Check your router’s belts too since they need to have the right tension. They may also have other defects, like missing chunks that can lead to chatter. CNC Router 3018 Pro is a desktop CNC starter kit milling machine for educational of CNC project, A new hobby CNC machine for you. Hey guys, you asked for it, we deliver! This video above will show you how to assemble SainSmart Genmitsu CNC Router 3018 Pro step by step, credits to Caleb Builds 3D. Increase the precision of Genmitsu CNC Router Provided by SainSmart Customer Here follows what I did to the Genmitsu 3018-PRO CNC Router (Now only 9) to achieve the precision I needed: First the result, PCB 44 x 32 mm with 0.6 mm drilled holes, the drill bit lying on top for comparison is a 1 mm diameter: Tweak 1. I need to machine small plastic parts from 24in or 27in wide x 8ft long plastic sheets, mainly in 0.5in and 0.75in thick HDPE (high density polyethylene), but also in wood for cheaper prototypes. The largest parts will be approx. 9in wide x 24in long. Smaller parts will be like the 3-point handle in the picture below, approx. 8in x 8in.

Picking up a part and setting a perfect starting point is not easy to do when accuracy is required. Using a 3D Touch Probe makes this processed super simple.

how to make a cnc router

cnc router top clamping

The WAGOBOX Light 207-3303 is a PUSHWIRE and Cage Clamp (PCC) junction box, designed for be used with the WAGO 224, 260, 294 series connectors. Easy to use and simple to fit, .

how to register part on cnc router|cnc router top clamping