welding sheet metal Welding sheet metal can be difficult. This 2 part video explains & demonstrates the basic techniques and tips for first time sheet metal welders. LINK TO BUY. Application of Titanium CNC Parts . Material: titanium; Size: 100% customized. Surface finish: PVD; Other service: laser etch logo/pattern. Titanium alloy has high strength, good corrosion resistance and high heat resistance. Corrosion resistant titanium alloys and high strength titanium alloys have been further developed.

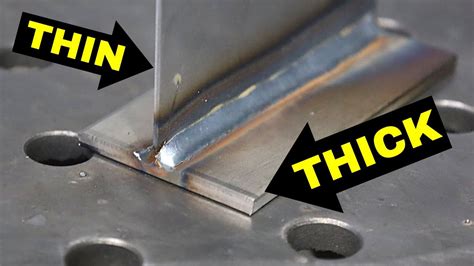

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

At United Steel Supply, we offer steel coil products designed for use in agriculture, residential and commercial construction, and industrial applications. Suitable for metal roofing or siding, our .

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See more

Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more

Learn how to avoid warping, burn-through and excessive heat-affected zones when welding thin metal with MIG, pulsed MIG, TIG and pulsed TIG processes. Find out the best .

Welding sheet metal can be difficult. This 2 part video explains & demonstrates the basic techniques and tips for first time sheet metal welders. LINK TO BUY. How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten. Ditch a 1/8-inch tungsten electrode for something much . Welding autobody panels. Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. Welding nearly always causes some . When welding thin sheet metal, do not try to run one bead right across the joint. This will cause too much heat to build up. Instead, run a series of short welds at different points in the metal that eventually join together. Leave the metal to cool for a second or two between welds to help the heat dissipate.

How To Weld Sheet Metal The RIGHT WAY - SUPER EASY#howto #diy #welding My Friend Pete shows us the easiest and simplest way to weld sheet metal. From butt w. Introduction. Welding is a primary process in sheet metal fabrication, characterized by high labor intensity and harsh working conditions.As such, high proficiency is essential. Automation in welding and the development of innovative joining methods have been consistent focal points for professionals in welding technology.. A pivotal aspect of welding automation is .

When you MIG weld any metal sheet, you must look at and care for two things. Burning through the sheet itself. Warping of the sheet, especially the edges; Creating excess heat and burning through one part of the sheet is easy. Even the most experienced welders find it hard to control the heat. It can only be achieved with patience and practice .

welding thin to thick metal

welding 14 gauge sheet metal

cnc machining milling service precision metal parts

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.Try going for a wire of .023 inches when welding sheet metal. For sheet metal, I use INE welding wire and it is just as good as their flux-cored wire, if you want, you can grab one here: https://amzn.to/37BeVJ1; While wire feed welding sheet metal, go for short bursts of welding instead of a going on a long bead. Short bursts or tacks will help .

Welding sheet metal with a wire feed welder is a skill that combines art and science, offering a robust solution for joining thin materials. This method is renowned for its precision, efficiency, and the strength of the welds it produces. As technologies evolve, so does the approach to welding, making it essential for enthusiasts and . Can You Weld 22-Gauge Sheet Metal? You can weld a 22-gauge (0.03-inches) metal sheet using a TIG welder or even with a MIG welding unit. However, it is not recommended to stick weld 22-gauge sheet metal as excessive penetration is . Welding is a process that joins metal parts together. It is one of the most common methods for making connections between metal objects, and there are many different types of welding. is Sheet metal welding a subset of welding used to construct metal structures, piping, and other things such as storage tanks?

Gas welding sheet metal is a great way to join two pieces together quickly and efficiently without having to rely on traditional methods such as soldering or brazing. With the right tools and know-how, however, anyone can become a master at gas welding sheet metal in no time! Keep these tips in mind as you get started on your next project . The advantage of the small diameter is that the 1/16″ will create an arc at much lower Amps and therefore also have less heat input, which creates warping in the metal sheet. Setting up the Stick Welder for Sheet Metal. .

MIG welding sheet metal requires a combination of technical expertise, precision, and dedication to continuous improvement. By understanding the nuances of sheet metal welding, considering critical factors, .

There is no hard and fast rule with the thickness under which you shouldn’t use stick welding.But there is a fair idea of what constitutes a thin metal and below which using stick welding might become difficult. A lot of people consider anything less than 3/16” to be thin so . In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. It provides strong, durable joints that are resistant to corrosion and wear. Braze welding is a method of joining two metal surfaces by heating them to a .

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.3 Methods of Welding Sheet Metal: There are many different methods for sheet metal welding, but the three we are going to discuss are MIG (metal inert gas), TIG (tungsten inert gas), and laser welding. The method used will depend on many factors. Below are things to consider for each of the three methods. In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v. Welding sheet metal can be a nightmare with all of the warping and blow through caused by excessive heat. In this video I will be showing you 4 different te.

MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. Metal inert gas is then used to protect the weld from contaminants. The variety of metals that can be welded through the MIG process .

Sheet metal welding is a multifaceted craft that requires applying numerous techniques. Acquiring the requisite knowledge and skills is imperative to perform welding with optimal outcomes. This article examines the diverse techniques employed in welding sheet metal materials, including their merits and practical uses. Additionally, it explains .Welding Sheet Metal. Home. Welding is a commonly used metal fabrication process that joins pieces of materials together. The weld, is achieved by partially melting the work pieces at a chosen point, sometimes adding a filler material, to form a pool of molten material that cools, solidifies and becomes a joint. .

Preparing the Sheet Metal for Plug Welding Sheet Metal. Before initiating the plug welding sheet metal process, it’s imperative to prepare the sheet metal to ensure optimal weld quality and structural integrity. The following steps outline the essential preparations for achieving successful plug welds:

cnc machining mechanical part supplier

welder settings for sheet metal

$9.99

welding sheet metal|welding 14 gauge sheet metal