3d printing vs cnc machining 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making . Western Metal Service is a manufacturing facility in Bloomington, California, with a focus in creating custom, high-quality products with a team of experienced professionals. Want to know more? Western Metal Service has been in business for over 30 years.

0 · subtractive manufacturing 3d printing

1 · machining 3d printed parts

2 · cnc printing

3 · cnc mill 3d printer

4 · cnc machine vs 3d printer

5 · cnc 3d printer

6 · alternatives to cnc machining

7 · 3d printer and cnc machine

$137.99

Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. CNC machining is one of the most common subtractive manufacturing technologies. See more 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making . CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds .As manufacturing technology advances, the debate between CNC (Computer Numerical Control) machining and 3D printing has become increasingly relevant. Both technologies offer unique .

subtractive manufacturing 3d printing

machining 3d printed parts

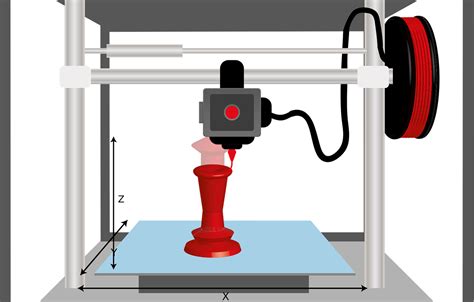

CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar .3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). . Compare the advantages and disadvantages of 3D printing and CNC machining for low-to-mid production. Learn about the differences in materials, accuracy, speed, cost, and geometric complexity of these two .

3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need.

Before we dive into the details, there’s an important fact to consider: CNC machining and 3D printing are not rivals. They’re complementary technologies that can work together to help you achieve your manufacturing goals. .3D printing is a type of additive manufacturing, whereas CNC machining is a form of subtractive manufacturing. In simple words, CNC machining involves cutting away material from a block of .Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. CNC machining is one of the most common subtractive manufacturing technologies.

electrical box for meter

cnc printing

electrical box for ceiling fan lowes

3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. It . CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds material layer by layer.As manufacturing technology advances, the debate between CNC (Computer Numerical Control) machining and 3D printing has become increasingly relevant. Both technologies offer unique advantages and are suitable for different applications. But when it comes to choosing the right process for your project, which one is better? CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications. This article discusses a detailed review and a distinction between CNC machining vs 3D printing.

3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). 3D printing doesn’t require special tooling or fixtures, so the initial setup cost is minimal compared to CNC machining. Other 3D printing advantages .

We decided to compare the advantages and disadvantages for each method to establish where these technologies are most appropriate. They key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, whilst CNC machining is subtractive.3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need.Before we dive into the details, there’s an important fact to consider: CNC machining and 3D printing are not rivals. They’re complementary technologies that can work together to help you achieve your manufacturing goals. However, each technology has its strengths and weaknesses. Knowing when to use each one can be the key to success.

3D printing is a type of additive manufacturing, whereas CNC machining is a form of subtractive manufacturing. In simple words, CNC machining involves cutting away material from a block of raw material to create the finished part.Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. CNC machining is one of the most common subtractive manufacturing technologies. 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making complex net shapes. It .

cnc mill 3d printer

CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds material layer by layer.

As manufacturing technology advances, the debate between CNC (Computer Numerical Control) machining and 3D printing has become increasingly relevant. Both technologies offer unique advantages and are suitable for different applications. But when it comes to choosing the right process for your project, which one is better?

CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications. This article discusses a detailed review and a distinction between CNC machining vs 3D printing.

3D printing, or additive manufacturing, involves parts being created layer by layer using materials such as plastic filaments , resins (SLA/DLP), or plastic and metal powders (SLS/DMLS/SLM). 3D printing doesn’t require special tooling or fixtures, so the initial setup cost is minimal compared to CNC machining. Other 3D printing advantages . We decided to compare the advantages and disadvantages for each method to establish where these technologies are most appropriate. They key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, whilst CNC machining is subtractive.3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need.

Before we dive into the details, there’s an important fact to consider: CNC machining and 3D printing are not rivals. They’re complementary technologies that can work together to help you achieve your manufacturing goals. However, each technology has its strengths and weaknesses. Knowing when to use each one can be the key to success.

electrical box for drop ceiling

This is the end to a rod that runs across the entire downstairs ceiling (above the plaster), exiting on the opposite exterior wall. The decorative plates and nuts were then tightened to clamp the .

3d printing vs cnc machining|cnc mill 3d printer