12 x 12 sheet metal for bending Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, . The noise is coming from the two transformers mounted to the side of the box. Transformers hum, it is just a fact of life.

0 · sheet metal bending strength

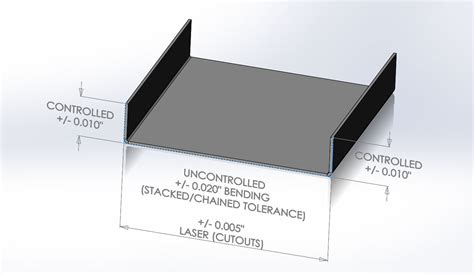

1 · sheet metal bending standards

2 · sheet metal bending height

3 · sheet metal bending dimensions

4 · sheet metal bending diagram

5 · sheet metal bend

6 · bending sheet metal from steel

7 · bending sheet metal 0.020

The most common causes for a burning smell in your house are burnt food, dust on the furnace, and clogged air ducts. A burning smell can also spread throughout your house if you constantly run a space heater or if it is dirty.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are .

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet .In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet .

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. .

In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere!

sheet metal jobs ireland

sheet metal bending strength

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.

sheet metal bending standards

sheet metal jobs winnipeg

It originated between the 18th and 19th centuries in the United States, particularly among the German-American farming communities in Pennsylvania. Initially, these stars were painted directly onto barns for their .

12 x 12 sheet metal for bending|sheet metal bending height