1018 or 1023 sheet metal 1023 Carbon Steel and Mechanical Properties, Chemical Element, Cross Reference, Datasheet. There are different types of CNC coolants available, such as synthetic fluids, semi-synthetic fluids, straight oils, and soluble oils. Consider factors like the material being machined, the cutting process, and cooling requirements when selecting a coolant.

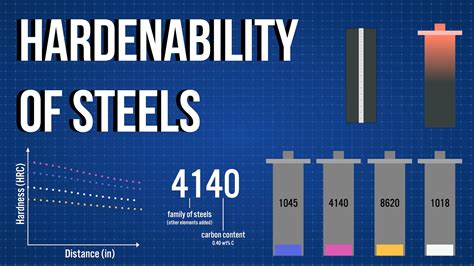

0 · hardenability of 1018 steel

1 · 1023 steel spec sheet

2 · 1023 steel datasheet

3 · 1018 steel rods

4 · 1018 steel for sale

5 · 1018 steel balls

6 · 1018 low carbon steel

7 · 1018 grade steel

Miniature Circuit Breakers (MCB): A miniature circuit breaker controls the supply to various miniature circuits on the main circuit. They switch off if they detect an overcurrent i.e. current that supersedes the circuit’s current rating.

Choose from our selection of grade 1018 steel, including steel, tool steel, and more. In stock and ready to ship.1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with many welding .1023 Carbon Steel and Mechanical Properties, Chemical Element, Cross Reference, Datasheet.

1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with . Explore the comprehensive guide to SAE 1018 steel, covering its chemical composition, equivalent materials, properties, and versatile uses. Gain insights into why SAE . 1018 steel is a versatile, adaptable, medium-low carbon steel that exhibits excellent weldability, machinability, formability, and strength compared to lower carbon steel when in a normalized and hot forged state.Learn important details about carbon-steel 1018 and other metals using the OnlineMetals.com® Product Guide.

Discover the AISI 1018 carbon steel - learn about its properties, composition, and applications for machining, welding, and fabrication.

hardenability of 1018 steel

SAE/AISI 1023 steel is used in the production of components that require good formability, such as wire, rods, and structural parts. It is commonly employed in cold-heading and cold-extrusion processes due to its excellent workability. .Choose from our selection of grade 1018 steel, including steel, tool steel, and more. In stock and ready to ship. In its cold drawn state, 1020 has high machinability and is a preferred steel grade for many manufacturers. 1018 steel is used over 1020 for applications that require machining, as it responds to machining fairly well. 1018 is most commonly used in high volume screw machine parts including shafts, spindels, pins and rods.1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with many welding techniques to create strong joints.

1023 Carbon Steel and Mechanical Properties, Chemical Element, Cross Reference, Datasheet.

1023 steel spec sheet

1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with many welding techniques to create strong joints. Explore the comprehensive guide to SAE 1018 steel, covering its chemical composition, equivalent materials, properties, and versatile uses. Gain insights into why SAE 1018 is an ideal choice for various industrial applications, from .

1018 steel is a versatile, adaptable, medium-low carbon steel that exhibits excellent weldability, machinability, formability, and strength compared to lower carbon steel when in a normalized and hot forged state.

Learn important details about carbon-steel 1018 and other metals using the OnlineMetals.com® Product Guide. Discover the AISI 1018 carbon steel - learn about its properties, composition, and applications for machining, welding, and fabrication.

SAE/AISI 1023 steel is used in the production of components that require good formability, such as wire, rods, and structural parts. It is commonly employed in cold-heading and cold-extrusion processes due to its excellent workability. The following table provides a list of SAE/AISI 1023 properties in both SI and US customary/Imperial units.Choose from our selection of grade 1018 steel, including steel, tool steel, and more. In stock and ready to ship. In its cold drawn state, 1020 has high machinability and is a preferred steel grade for many manufacturers. 1018 steel is used over 1020 for applications that require machining, as it responds to machining fairly well. 1018 is most commonly used in high volume screw machine parts including shafts, spindels, pins and rods.

sheet metal fabricator message board

1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with many welding techniques to create strong joints.1023 Carbon Steel and Mechanical Properties, Chemical Element, Cross Reference, Datasheet.

1018 cold-drawn steel has improved machinability, better tensile strength, and higher yield than 1018 hot-rolled steel. It’s also ideal for welding purposes and works with many welding techniques to create strong joints. Explore the comprehensive guide to SAE 1018 steel, covering its chemical composition, equivalent materials, properties, and versatile uses. Gain insights into why SAE 1018 is an ideal choice for various industrial applications, from . 1018 steel is a versatile, adaptable, medium-low carbon steel that exhibits excellent weldability, machinability, formability, and strength compared to lower carbon steel when in a normalized and hot forged state.

Learn important details about carbon-steel 1018 and other metals using the OnlineMetals.com® Product Guide. Discover the AISI 1018 carbon steel - learn about its properties, composition, and applications for machining, welding, and fabrication.

sheet metal fabricators denver colorado

1023 steel datasheet

Junction boxes usually use a heavier duty screw, an 8-32. Junction boxes often hold heavier light fixtures, so they need a screw that can hold a bit more weight. 8-32 is a very common size, at least. An 8-32 is .164 inches in diameter, which is a shade over 5/32.

1018 or 1023 sheet metal|1018 low carbon steel