electrical conduit pull boxes Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves . To figure out which metal roof is right for you, it’s important to weigh the pros and cons of each type. 1. Aluminum is one of the best metal roofing types, thanks in part to its longevity and strong wind and fire resistance.

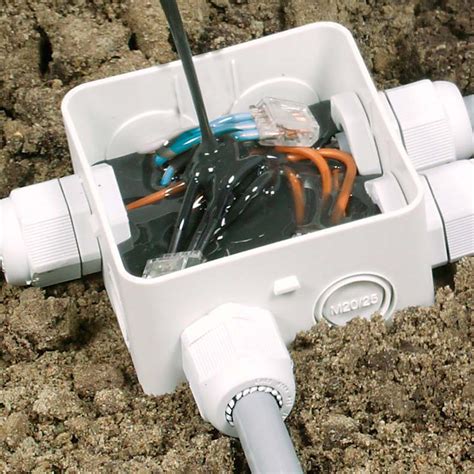

0 · underground waterproof electrical box

1 · underground electrical pull box sizes

2 · underground electrical pull box

3 · underground concrete electrical pull box

4 · standard pull box size chart

5 · sizing electrical pull boxes

6 · pull box sizing chart

7 · minimum distance between pull boxes

There are various materials that can be used to produce sheet metal: Aluminum: Lightweight and resistant to corrosion, aluminum is .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, .Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using .

Make sure you know the proper sizing requirements for pull boxes, junction .Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves .

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Make sure you know the proper sizing requirements for pull boxes, junction boxes, and conduit bodies to avoid damaging the conductor insulation when installing conductors 4 AWG and larger. Courtesy of www.MikeHolt.com. .For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with .For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According .Place pull boxes in sections of conduit that: Are 30 m (98 ft.) or more in length. Contain more than two 90" bends. Contain a reverse bend. Do not use a pull box in lieu of a bend. Align conduits .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Make sure you know the proper sizing requirements for pull boxes, junction boxes, and conduit bodies to avoid damaging the conductor insulation when installing conductors 4 AWG and larger. Courtesy of www.MikeHolt.com. Based on the 2020 NEC.For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following: Straight pulls. A conductor that enters one wall of a box and leaves through the opposite wall is a straight pull.For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

underground waterproof electrical box

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.Place pull boxes in sections of conduit that: Are 30 m (98 ft.) or more in length. Contain more than two 90" bends. Contain a reverse bend. Do not use a pull box in lieu of a bend. Align conduits that enter the pull box from opposite ends with each other. Use the following table to select the proper size of pull box. 102 mm (4in.)

round electrical box old work

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Make sure you know the proper sizing requirements for pull boxes, junction boxes, and conduit bodies to avoid damaging the conductor insulation when installing conductors 4 AWG and larger. Courtesy of www.MikeHolt.com. Based on the 2020 NEC.

For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following: Straight pulls. A conductor that enters one wall of a box and leaves through the opposite wall is a straight pull.For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.

underground electrical pull box sizes

underground electrical pull box

Material stretched into shape •Stretch forming – very cheap tooling, net thinning, slow, low formability •Super-plastic forming – cheap tooling, net thinning, expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed .

electrical conduit pull boxes|underground electrical pull box sizes