tig welding galvanized mild steel sheet metal To help you understand how to set up a TIG welder for mild steel, we’ll cover how TIG welding works on mild steel, the TIG power supplies you’ll need, the TIG torch options for welding mild steel, how to set-up your . $12.70

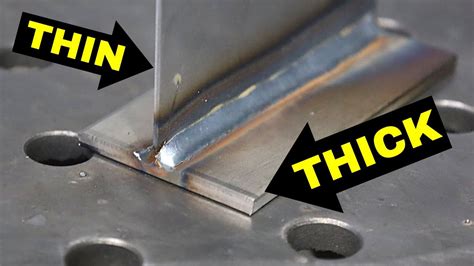

0 · welding thin to thick metal

1 · welding stainless steel sheet metal

2 · welding sheet metal without warping

3 · welding 14 gauge sheet metal

4 · tig welding stainless sheet metal

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

Go ultra-modern with a gray palette incorporating stainless steel; move to the warm side of the color spectrum by emphasizing browns and golds; or consider a French Provencal look with dramatic blue granite countertops.

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal.TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise .

Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. A galvanized square tubing on a galvanized sheet metal. Most often, the steel under the coating steel is mild steel, which is the easiest metal to weld. However, according to the service conditions of the metal, you may have .

To help you understand how to set up a TIG welder for mild steel, we’ll cover how TIG welding works on mild steel, the TIG power supplies you’ll need, the TIG torch options for welding mild steel, how to set-up your . In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. TIG welding, or Tungsten Inert Gas welding, is a precise welding process that uses a non-consumable tungsten electrode to create the weld. This method is ideal for welding thin materials such as galvanized sheet metal due . TIG welding galvanized steel requires specific techniques to ensure a quality weld. In this section, we will discuss the TIG welding process for galvanized steel, the best TIG welding practices, joint design, and weld .

Tig welding is a versatile and powerful technique that is used for welding stainless steel, aluminum, and mild steel. In this blog post, we will take a look at how to use tig welding for mild steel. We’ll discuss the best practices .

To weld mild steel, choose an American Welding Society classification wire such as ER70S-6, which has a weld puddle that wets out nicely. Always use a higher argon-based shielding gas, such as 75% .

To increase productivity when joining galvanised sheet metal, metal inert gas (MIG) and tungsten inert gas (TIG) arc brazing are combined in a hybrid process. This coupling of two arc processes increases brazing speed and reduces weld reinforcement and the tendency to spatter. Because the arcs are 6 mm apart, they influence each other. Therefore, the blowing .How To Weld Galvanized Steel! by DIY Welder: Welding galvanized metal is dangerous because zinc oxide is released into the air as the metal melts. Good ventilation is required. If the galvanized is not burned off prior to welding then a poor weld will be the result. I use an acetylene torch to burn off galvanized prior to welding and utilize a . The most common method for joining galvanized steel to mild steel is MIG (inert metal gas) welding, although TIG (inert tungsten gas) and oxy-acetylene processes can also be used if necessary. MIG welding has become increasingly popular due to its ease of use and its ability to quickly join two pieces together without creating too much heat or .St. Ann's Sheet Metal Company based in Nottingham, East Midlands manufacture a wide range of sheet metal components using CNC Punching,CNC Bending and Laser Cutting in Mild Steel, Stainless Steel, Aluminium, Galvanised Steel, Zintec, Brass and Brass Plate. . TIG Welding. Between the tungsten electrode and the workpiece an arc is formed .

galvanized sheet. When the higher heat used with other welding rods is used on galvanized, the zinc boils and out gasses. But because of its low melt point, silicon bronze tig brazing works better on galvanized sheet than welding with mild steel rods. Metal art. the gold look of silicon bronze makes stuff look cool. 2. Can you weld galvanized steel without the zinc coating? Absolutely not; the zinc coating is what makes the steel galvanized. 3. What does “flux” mean in the context of welding galvanized steel? Fluxing removes the oxide film resulting from acid cleaning. Final Thoughts. Ecenrode Welds has got you covered for your galvanized steel welding .High deposition rates and faster travel speeds are the greatest productivity- and quality-advantages of metal-cored wire for galvanized steel, like Hobart® FabCOR ® F6 (American Welding Society E70C-GS). For example, FabCOR F6 metal-cored wire is designed to produce limited subsurface porosity at 40 inches per minute, compared to 23 or 25 . Challenges of welding galvanized steel. Welding galvanized steel presents several challenges that need to be addressed to ensure a successful weld. One of the main challenges is the release of toxic fumes when the zinc coating is heated. These fumes can cause health hazards, such as metal fume fever, which is characterized by flu-like symptoms.

Rods with a cellulose coating, like 6010 or 6011, are the best for welding galvanized steel because their strong arc vaporizes the zinc better than other rods.These electrodes also have a low silicone content, reducing the possibility of weld cracking. The whip technique used when welding with a 6010 or 6011 electrode burns off the zinc ahead of the weld puddle. Welding Galvanized To Mild Steel. Welding galvanized steel to mild steel is a common task in many industries. The process, though essential, poses some challenges. Understanding these challenges and following expert tips can ensure a successful weld. Why It’s Challenging. Galvanized steel has a zinc coating that protects it from corrosion.Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal for welding mild steel. For the inert gas, aim at having more argon to carbon dioxide – 75% argon to 25% .

Master TIG welding sheet metal with expert techniques, essential tools, and pro tips. . Match your filler to the base metal: For mild steel, ER70S-2 or ER70S-6 work well. Stainless steel typically uses ER308L or ER316L. . It’s less ideal for galvanized steel. Cast iron is challenging. For most common fabrication metals, TIG is excellent . Anybody have any advice on tig welding 18 gauge steel? I can seem to do 16 gauge alright way down at 9 amps but 18 gauge is just blow through from the moment I pull the trigger. . It's up to you to manipulate sheet metal to perfect position, then tack, often an inch at a time. Reply . 05-20-2014 #15. Willie B. View Profile View Forum Posts .The first is to spot weld some galvanized steel together as a part of a larger project. I brought up the toxicity to my teacher and he said it wasn't a big deal. About 25 students are going to be making about 12-24 spot welds each on something like .

The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which . Aluminized steel comes mostly as thin piping, tubing, and sheet metal. The most common thicknesses are between gauge 10 (.138″ – 3.5 mm) down to gauge 30 (.016″ – 0.4 mm). Most aluminized steels are basically mild .

welding thin to thick metal

welding stainless steel sheet metal

TIG Welding Mild Steel. When TIG welding mild steel, you’ll want to use a DCEN (direct current electrode negative) polarity, Argon gas, and Thorium Tungsten. You’ll need to keep in mind when you weld any steel that you’ll have to shape the Tungsten to a fine point. Welding steel is very similar to welding other types of materials.

Harris mild steel alloys are perfect for welding cold rolled steel in thicknesses from thin sheet metal to thick plate steel. Conforming to AWS 5.18, these products are subjected to rigid quality control throughout the manufacturing process with particular attention given to cleanliness, cast and helix, resulting in a superior finished product.Mild, Galvanized and Aluminized Steel Sheet Metal Fabrication Services Since we were founded in 1895, we have built a reputation of expert workmanship with sheet metal. Schebler Specialty Fab works with sheet metal ranging in thickness from 30 (0.012″/0.304mm) to .

welding sheet metal without warping

If you work in a sheet metal shop that makes ductwork all day (which I have) you know most ductwork is galvanized, but you occasionally make it in stainless or aluminum for specific industrial/medical applications or mild steel for specific restaurant applications.

welding 14 gauge sheet metal

TIG Welding Sheet Metal. Tungsten Inert Gas (TIG) welding, or Gas Tungsten Arc Welding (GTAW), requires more manual dexterity, offering high levels of precision and control. . Mild Steel – A filler like ER70S-6 generally works well. Use Skip Welding Techniques. Skip welding - distributing welds over a broader area - mitigates heat .Welding . TIG. TIG Consumables; TIG Machines; TIG Rod; General. Spare Parts; Cable and Lugs; . 24 inch x 36 inch Galvanized Mild Steel Sheet Metal, 26 Gauge, grade 60 mild steel sheet metal. WARRANTY. 30 Days: 30 Days: Product: Free of defects in material and workmanship that may occur under normal use and care. Hi all, Just wondering if anyone out there has specific experience with welding galvanized steel with the lower silicone version er70s-3 wire? I've read it was designed to combat cracking, but wondering if it helps out with porosity and pin . Welding galvanized steel to mild steel presents several challenges and considerations that need to be taken into account before attempting the process. One of the main challenges is the presence of the zinc coating on galvanized steel, which can have a negative impact on the weld.

TIG welding galvanized sheet metal requires proper ventilation to avoid zinc fumes exposure. Use a respirator for safety. Welding galvanized. TIG Welding, Welding Electrodes . TIG Welding, Mild Steel, Stainless Steel TIG Welding Stainless to Mild Steel. Darrell Julian - September 13, 2024 .

tig welding stainless sheet metal

If you don’t have any power tools, one of the very best ways to cut sheet metal is by using tin snips, otherwise known as tin scissors or metal shears. These are very special scissors, akin to very heavy-duty shears, that are used to cut sheet metal.

tig welding galvanized mild steel sheet metal|welding stainless steel sheet metal