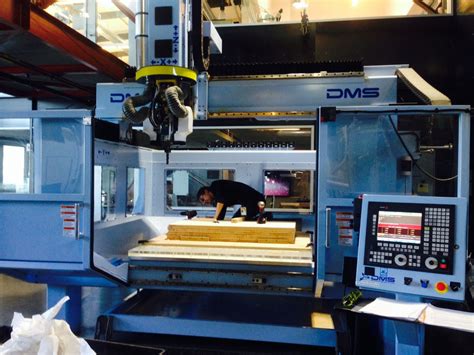

accurate 2 sided machining on cnc router One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of .

ICC Digital Codes has highlighted section 1136A which tackles the height of receptacles on a branch circuit 30A or less. If you measure the distance from the top of the outlet box, it shouldn’t exceed 48 inches. If you measure from the bottom to the finished floor, you’re looking at .

0 · how to engrave cnc on both sides

1 · cnc router flip machining

2 · cnc router 2 sided machining

3 · cnc from both sides

4 · 2 sided cnc router

Our skilled team of metal fabricators is dedicated to providing you with precision and expertise, ensuring that every project is executed to perfection. From custom metal designs to structural fabrication, we bring your ideas to life with attention to detail and a commitment to excellence.

In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid. I use VCarve . An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X and Y are key to making this. Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts.

Have you ever wanted to engrave your project on both sides making sure that both sides line up accurately? Well, now you can and I'll show you how! One way would be to use a purpose .

Making CNC cuts on both sides of the components aren't that difficult - First, you make the cuts on one side of the part, flip the material around, and use o.One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of . There are possibly many different ways to align and square a CNC router table gantry to get the best possible accuracy for cutting your parts. Parts that are not square can .

We drill two alignment holes along the vertical centerline of the part, one on the top and one on the bottom of the line. Next we extend those drilled holes into a sacrificial board clamped to .One of the great things you can do on a CNC router is a double-sided sign. There are some key points to making this work, and work correctly. – Controlling depth of cut so you don’t cut through when you cut both faces – Controlling the . Plus this is my first try at 2 sided using this method. I have always done it the "old fashioned" way on my first gen Shark Router. I used -.110 and -.070 on the limit planes. In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid. I use VCarve software (vectric.com) to design my CNC projects and output toolpaths.

An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X and Y are key to making this.

how to engrave cnc on both sides

Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts.Have you ever wanted to engrave your project on both sides making sure that both sides line up accurately? Well, now you can and I'll show you how! One way would be to use a purpose made jig to hold your stock and help you locate it after its flipped to the other side.

electrical pull box sizes

Making CNC cuts on both sides of the components aren't that difficult - First, you make the cuts on one side of the part, flip the material around, and use o.One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of CNC two-sided machining, including its benefits, setup procedures, tool . There are possibly many different ways to align and square a CNC router table gantry to get the best possible accuracy for cutting your parts. Parts that are not square can pose problems - especially if you want to do double sided machine.

We drill two alignment holes along the vertical centerline of the part, one on the top and one on the bottom of the line. Next we extend those drilled holes into a sacrificial board clamped to the router table.One of the great things you can do on a CNC router is a double-sided sign. There are some key points to making this work, and work correctly. – Controlling depth of cut so you don’t cut through when you cut both faces – Controlling the model position . Plus this is my first try at 2 sided using this method. I have always done it the "old fashioned" way on my first gen Shark Router. I used -.110 and -.070 on the limit planes.

cnc router flip machining

In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid. I use VCarve software (vectric.com) to design my CNC projects and output toolpaths. An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X and Y are key to making this.

Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts.Have you ever wanted to engrave your project on both sides making sure that both sides line up accurately? Well, now you can and I'll show you how! One way would be to use a purpose made jig to hold your stock and help you locate it after its flipped to the other side.

Making CNC cuts on both sides of the components aren't that difficult - First, you make the cuts on one side of the part, flip the material around, and use o.

One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of CNC two-sided machining, including its benefits, setup procedures, tool . There are possibly many different ways to align and square a CNC router table gantry to get the best possible accuracy for cutting your parts. Parts that are not square can pose problems - especially if you want to do double sided machine.

We drill two alignment holes along the vertical centerline of the part, one on the top and one on the bottom of the line. Next we extend those drilled holes into a sacrificial board clamped to the router table.One of the great things you can do on a CNC router is a double-sided sign. There are some key points to making this work, and work correctly. – Controlling depth of cut so you don’t cut through when you cut both faces – Controlling the model position .

cnc router 2 sided machining

electrical rough in boxes

electrical service breaker box

Vintage Walt Disney School Bus Metal Lunch Box Thermos Bottle Aladdin Yellow. Find great deals on eBay for Disney School Bus Lunch Box. Shop with confidence.

accurate 2 sided machining on cnc router|2 sided cnc router