cnc lathe machine g codes pdf G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex . We ultimately selected the five best CNC machines and routers for woodworking in 2024 based on their proven track record, ease of use, and precision. Our blog post provides detailed information on each machine and router, including their features, specifications, and pricing, to help readers make an informed buying decision.

0 · list of g codes cnc

1 · list of fanuc g codes

2 · cnc turning g code list

3 · cnc mill g code list

4 · cnc lathe g codes list

5 · cnc lathe g code examples

6 · cnc g code list download

7 · cnc g code chart

What Is The Definition Of Enswell In Boxing & MMA? 1. An enswell is a piece of metal that has a handle. It is usually kept on ice and is used to help cool the area of a bruise or cut by directly applying pressure on the wound with the metal.It's an eye iron. It's a piece of steel that can be super-cooled to reduce swelling on a fighter's face, so they can continue to see throughout the match.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –Section 3 numerically lists the full range of G Codes available on Denford CNC milling machines, whilst section 4 numerically lists the full range of M Codes available.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC .g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non .

G50 - Set coordinate system and maximum RPM; Lathe G52 - Local coordinate system setting; Mill and Lathe G53 - Machine coordinate system setting; Mill and Lathe

This Downloadable PDF contains two lists of G-codes and M-codes for both Machining centers and lathes for most machine builders. Download consists of one G and M code cheat sheet on .

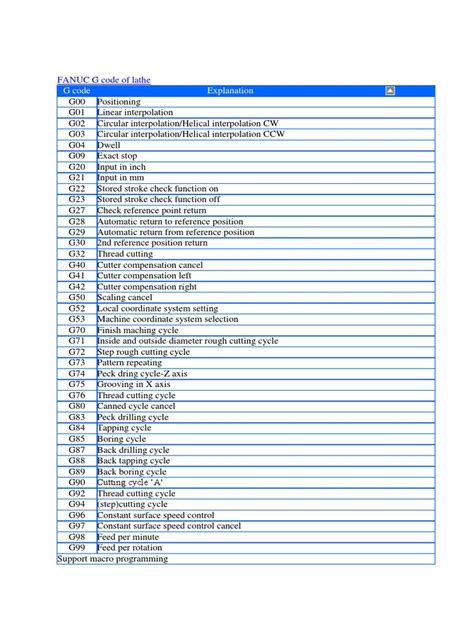

The document lists G and M codes used in CNC lathe programming. G codes control linear and circular interpolation, tool compensation, cycles, and coordinate systems. M codes control functions like spindle control, coolant, tapping, .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times andG Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –

Section 3 numerically lists the full range of G Codes available on Denford CNC milling machines, whilst section 4 numerically lists the full range of M Codes available.

Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non-modal (x,z,b) g54 work offset coordinate positioning #1 (setting 56) g55 work offset coordinate positioning #2 g56 work offset coordinate positioning #3

G50 - Set coordinate system and maximum RPM; Lathe G52 - Local coordinate system setting; Mill and Lathe G53 - Machine coordinate system setting; Mill and LatheThis Downloadable PDF contains two lists of G-codes and M-codes for both Machining centers and lathes for most machine builders. Download consists of one G and M code cheat sheet on a 8.5 X 11 page with all the basic information you may need to modify most programs on most machines on the spot.

The document lists G and M codes used in CNC lathe programming. G codes control linear and circular interpolation, tool compensation, cycles, and coordinate systems. M codes control functions like spindle control, coolant, tapping, chucks, tailstocks, mirroring, and subprograms.G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and

list of g codes cnc

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –Section 3 numerically lists the full range of G Codes available on Denford CNC milling machines, whilst section 4 numerically lists the full range of M Codes available.

Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?g51 return to machine zero, cancel offset (yasnac) g52 work offset coordinate positioning (yasnac) g52 global work coordinate system shift (fanuc) g53 machine coordinate positioning, non-modal (x,z,b) g54 work offset coordinate positioning #1 (setting 56) g55 work offset coordinate positioning #2 g56 work offset coordinate positioning #3G50 - Set coordinate system and maximum RPM; Lathe G52 - Local coordinate system setting; Mill and Lathe G53 - Machine coordinate system setting; Mill and LatheThis Downloadable PDF contains two lists of G-codes and M-codes for both Machining centers and lathes for most machine builders. Download consists of one G and M code cheat sheet on a 8.5 X 11 page with all the basic information you may need to modify most programs on most machines on the spot.

jose sheet metal mesa

jump from outlet to outlet or junction box

What Is The Best Glue For Fabric To Metal? The best glue for bonding fabric to metal depends on the specific project requirements and materials involved. Epoxy-based adhesives are often considered effective for fabric-to-metal bonding due .

cnc lathe machine g codes pdf|cnc lathe g codes list