define sheet metal forming process Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end . With 50 percent more harness ports, alleviates the need for multiple boxes, while allowing for the addition of more harness systems and increased lighting needs. Clear lid offers easy viewing of connections without having to remove lid, saving time when trying to identify lighting system problems.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal operations with diagrams

4 · sheet metal forming process pdf

5 · sheet metal bending process pdf

6 · forming sheet metal by hand

7 · bulk deformation vs sheet metal forming

ATB is a Manufacturer of custom and standard truck boxes and toolboxes for pickup trucks, trailers, and semi-trucks. Great for truckers, contractors, sportsmen, service vehicles and more.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal .

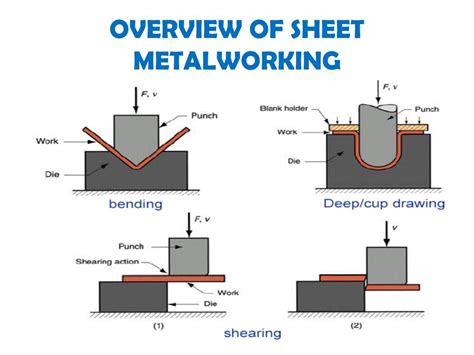

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, . Sheet metal forming is associated with operations; Bending, Drawing, Shearing, Blanking, and Punching to produce the materials. The sheet forming method uses plastic .

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, .

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end . Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products using an array of manufacturing . Sheet metal drawing is defined as a plastic deformation over a curved axis. It’s a process that uses tensile forces to elongate the metal. As the material is drawn (pulled), it stretches and becomes thinner, achieving a . Sheet metal forming, also known as precision sheet metal forming, is a crucial process in the manufacturing industry. It involves transforming flat metal sheets into desired shapes through mechanical and .

Definition. Sheet metal forming is a manufacturing process that involves shaping and transforming flat sheets of metal into desired shapes through various techniques like bending, stretching, . In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet metal parts. Because manufacturers typically perform these operations on presses with a set of dies, the terms pressworking or press .

sheet metal working process pdf

sheet metal stamping process pdf

junction box for 4p5w

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Sheet metal forming is associated with operations; Bending, Drawing, Shearing, Blanking, and Punching to produce the materials. The sheet forming method uses plastic sheet deformation techniques such as Deep Drawing, Cutting, Bending, Hemming, Flanging, Curling, Stretch Forming/Stretching, Stamping. In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. Understanding Sheet . Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products using an array of manufacturing techniques. Sheet metal drawing is defined as a plastic deformation over a curved axis. It’s a process that uses tensile forces to elongate the metal. As the material is drawn (pulled), it stretches and becomes thinner, achieving a specific shape and thickness.

Sheet metal forming, also known as precision sheet metal forming, is a crucial process in the manufacturing industry. It involves transforming flat metal sheets into desired shapes through mechanical and hydraulic processes such .Definition. Sheet metal forming is a manufacturing process that involves shaping and transforming flat sheets of metal into desired shapes through various techniques like bending, stretching, and stamping. This process is critical in industries such as automotive and aerospace, as it allows for the production of lightweight yet durable components.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet metal parts. Because manufacturers typically perform these operations on presses with a set of dies, the terms pressworking or press . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Sheet metal forming is associated with operations; Bending, Drawing, Shearing, Blanking, and Punching to produce the materials. The sheet forming method uses plastic sheet deformation techniques such as Deep Drawing, Cutting, Bending, Hemming, Flanging, Curling, Stretch Forming/Stretching, Stamping.

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more. Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. Understanding Sheet . Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products using an array of manufacturing techniques. Sheet metal drawing is defined as a plastic deformation over a curved axis. It’s a process that uses tensile forces to elongate the metal. As the material is drawn (pulled), it stretches and becomes thinner, achieving a specific shape and thickness.

Sheet metal forming, also known as precision sheet metal forming, is a crucial process in the manufacturing industry. It involves transforming flat metal sheets into desired shapes through mechanical and hydraulic processes such .

junction box for 220 line

sheet metal processes pdf

Fortunately, there are truck bed repair panels that can help restore your truck’s cargo box. Whether you drive a Ford, Chevy, Dodge, Ram, or many other common truck models, you can replace your damaged truck bed sides or dinged-up truck bed floor with a complete replacement truck bed repair panel.

define sheet metal forming process|bulk deformation vs sheet metal forming