aircraft sheet metal basics Aviation Sheet Metal focuses on teaching basic aircraft structural skills. Students spend time in the classroom learning terminology, tools, equipment, blueprint reading and shop safety before moving into the shop for a hands-on experience.

Versatile and affordable, a fabric wardrobe is perfect for storage in spare bedrooms, student accommodation or utility rooms.

0 · sheet metal joggle examples

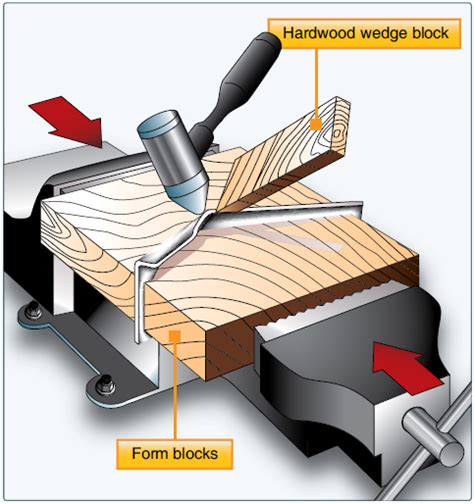

1 · sheet metal hand forming techniques

2 · lightening holes for aircraft

3 · aviation metal repair diagram

4 · airframe sheet metal mechanic ad

5 · aircraft sheet metal mechanic

6 · aircraft sheet metal lap patch

7 · aircraft sheet metal forming

Contact Us - TRINITY - Everything In its Place®

There are five basic steps in the process of building an aluminum airplane. These steps are: (1) Planning, (2) Basic building, (3) Assembly, rigging and systems installation, (4) .This sheet metal course was created to give you the ultimate experience in learning .Repairs to sheet metal airplanes fall into two categories: simple, which doesn't .In any aircraft sheet metal repair, it is critical to: Minimize weight. Certain fundamental rules must be observed if the original strength of the structure is to be maintained. Ensure that the cross-sectional area of a splice or patch is at .

Intro to aircraft sheet metal, drilling & rivetAviation Sheet Metal focuses on teaching basic aircraft structural skills. Students spend time in the classroom learning terminology, tools, equipment, blueprint reading and shop safety before moving into the shop for a hands-on experience.This sheet metal course was created to give you the ultimate experience in learning to build or restore your airplane. The following is a brief outline of the two-day course. Day one starts off .Sheet-metal floats should be repaired using approved practices; however, the seams between sections of sheet metal should be waterproofed with suitable fabric and sealing compound. A float that has undergone hull repairs should .

Repairs to sheet metal airplanes fall into two categories: simple, which doesn't involve damage to structural members or affect the balance of control surfaces, and major, which encompasses repairs not covered by the . One of the most exciting hands-on training projects at NAA is all about sheet metal! Learn about aircraft structures while cutting and forming sheet metal!EAA’s continuing "how-to" series of educational materials for building your own aircraft now includes Sheet Metal Building Basics, written by longtime builder and SportAir instructor Jack Dueck.EAA’s continuing “how-to” series of educational materials for building your own aircraft now includes, Sheet Metal Building Basics, written by longtime builder and SportAir instructor Jack .

sheet metal joggle examples

.85.95.95.10

sheet metal hand forming techniques

There are five basic steps in the process of building an aluminum airplane. These steps are: (1) Planning, (2) Basic building, (3) Assembly, rigging and systems installation, (4) Inspection, certification, and test flying, (5) Final painting.In any aircraft sheet metal repair, it is critical to: Minimize weight. Certain fundamental rules must be observed if the original strength of the structure is to be maintained. Ensure that the cross-sectional area of a splice or patch is at least equal to or greater than that of the damaged part. Avoid abrupt changes in cross-sectional area.

what is a 30 amp junction box used for

Intro to aircraft sheet metal, drilling & rivetAviation Sheet Metal focuses on teaching basic aircraft structural skills. Students spend time in the classroom learning terminology, tools, equipment, blueprint reading and shop safety before moving into the shop for a hands-on experience.

This sheet metal course was created to give you the ultimate experience in learning to build or restore your airplane. The following is a brief outline of the two-day course. Day one starts off with a discussion of the basics of sheet metal construction.Sheet-metal floats should be repaired using approved practices; however, the seams between sections of sheet metal should be waterproofed with suitable fabric and sealing compound. A float that has undergone hull repairs should be tested by filling it with water and allowing it to stand for at least 24 hours to see if any leaks develop. Repairs to sheet metal airplanes fall into two categories: simple, which doesn't involve damage to structural members or affect the balance of control surfaces, and major, which encompasses repairs not covered by the simple category. We'll address simple repairs here.

One of the most exciting hands-on training projects at NAA is all about sheet metal! Learn about aircraft structures while cutting and forming sheet metal!EAA’s continuing "how-to" series of educational materials for building your own aircraft now includes Sheet Metal Building Basics, written by longtime builder and SportAir instructor Jack Dueck.EAA’s continuing “how-to” series of educational materials for building your own aircraft now includes, Sheet Metal Building Basics, written by longtime builder and SportAir instructor Jack Dueck.

lightening holes for aircraft

There are five basic steps in the process of building an aluminum airplane. These steps are: (1) Planning, (2) Basic building, (3) Assembly, rigging and systems installation, (4) Inspection, certification, and test flying, (5) Final painting.In any aircraft sheet metal repair, it is critical to: Minimize weight. Certain fundamental rules must be observed if the original strength of the structure is to be maintained. Ensure that the cross-sectional area of a splice or patch is at least equal to or greater than that of the damaged part. Avoid abrupt changes in cross-sectional area.

Intro to aircraft sheet metal, drilling & rivetAviation Sheet Metal focuses on teaching basic aircraft structural skills. Students spend time in the classroom learning terminology, tools, equipment, blueprint reading and shop safety before moving into the shop for a hands-on experience.This sheet metal course was created to give you the ultimate experience in learning to build or restore your airplane. The following is a brief outline of the two-day course. Day one starts off with a discussion of the basics of sheet metal construction.Sheet-metal floats should be repaired using approved practices; however, the seams between sections of sheet metal should be waterproofed with suitable fabric and sealing compound. A float that has undergone hull repairs should be tested by filling it with water and allowing it to stand for at least 24 hours to see if any leaks develop.

aviation metal repair diagram

airframe sheet metal mechanic ad

Repairs to sheet metal airplanes fall into two categories: simple, which doesn't involve damage to structural members or affect the balance of control surfaces, and major, which encompasses repairs not covered by the simple category. We'll address simple repairs here. One of the most exciting hands-on training projects at NAA is all about sheet metal! Learn about aircraft structures while cutting and forming sheet metal!

EAA’s continuing "how-to" series of educational materials for building your own aircraft now includes Sheet Metal Building Basics, written by longtime builder and SportAir instructor Jack Dueck.

aircraft sheet metal mechanic

Business Profile for Tri-Star Roofing, LLC. Roofing Contractors. At-a-glance. Contact Information. 313 C C Camp Rd, Cookeville, TN 38501. Get Directions (931) 251-9595. Customer Reviews.

aircraft sheet metal basics|aircraft sheet metal forming