cnc lathe machine notes The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with incredible precision makes it a cornerstone in modern manufacturing processes.

Ballucci Modern Interlocking Cube Floating Shelves, Wall Mount Wood Square Shelves for Living Room, Bedroom, Bathroom, Easy to Install Wall Decor Box Shelves, Black

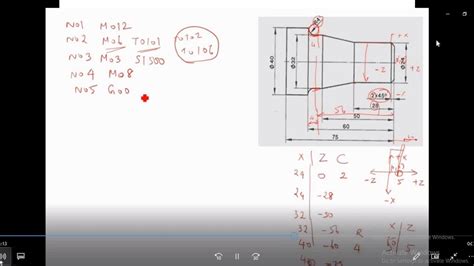

0 · cnc turning program examples pdf

1 · cnc turning machine programming pdf

2 · cnc turning cycle program pdf

3 · cnc programming PDF free download

4 · cnc programming For Dummies pdf

5 · cnc machine parts list pdf

6 · cnc machine operation manual pdf

7 · cnc lathe manual pdf

Legrand Wiremold V5747-2 Metal Raceway for Extending Power, 500 and 700 Series, 2 Gang Switch and Outlet Box, 1 3/8" Deep, Ivory (1 Pack) - Power Strips And Multi Outlets - Amazon.com

CNC Lathe Machine: Computer Numeric Control(CNC) is the most advanced form of the lathe machine. CNC lathe machine produces the most . Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at . CNC Lathe Machine: Computer Numeric Control(CNC) is the most advanced form of the lathe machine. CNC lathe machine produces the most accurate products as compared to the other type of the lathe machine. Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at distributors such as Amazon.

What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes. The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with incredible precision makes it a cornerstone in modern manufacturing processes.

CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.In this section, we will begin by providing a brief overview of CNC lathe machines, explaining their purpose and advantages over conventional lathes. We will delve into the history and evolution of these machines, laying the foundation for a deeper understanding of their parts and functions. A CNC lathe is a precision tool that uses computer programming to control the motion and operation of a cutting tool. The cutting tool is held in a tool turret and moves along the workpiece to create the desired shape or features. Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves.

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

cnc turning program examples pdf

Lathes can be configured with a horizontally mounted spindle (often equipped with a tailstock), a vertically mounted spindle, or a rotating table. This article will explore the key aspects of CNC lathes and provide valuable insights for those interested in understanding their functions, types, applications, and more. What is a Lathe Machine? CNC Lathe Machine: Computer Numeric Control(CNC) is the most advanced form of the lathe machine. CNC lathe machine produces the most accurate products as compared to the other type of the lathe machine. Although lathes can fit into several categories, there are three basic types of lathe machines: the traditional engine lathe, the computer numerical control (CNC) lathe, and the mini-lathe, or benchtop, often sold at distributors such as Amazon.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with incredible precision makes it a cornerstone in modern manufacturing processes.

CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.

In this section, we will begin by providing a brief overview of CNC lathe machines, explaining their purpose and advantages over conventional lathes. We will delve into the history and evolution of these machines, laying the foundation for a deeper understanding of their parts and functions.

cnc turning machine programming pdf

cnc turning cycle program pdf

cnc programming PDF free download

A CNC lathe is a precision tool that uses computer programming to control the motion and operation of a cutting tool. The cutting tool is held in a tool turret and moves along the workpiece to create the desired shape or features. Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves.

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

composite panels for junction boxes and ul nema wall-mount enclosures

company to pick metal recycling in mountain house c

We start with a general discussion of the concept and look at options for how you can accurately align a two sided part. We then look at an actual file and work through the basic two-sided.

cnc lathe machine notes|cnc turning cycle program pdf