cnc lathe machine programming codes I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function Tulip Fabric Spray Paint gives your fabrics an instant burst of bold color for a total transformation in minutes! This nontoxic and eco-friendly formula comes with a pump nozzle for complete control when spraying, whether you’re looking to achieve a fine mist or fun.

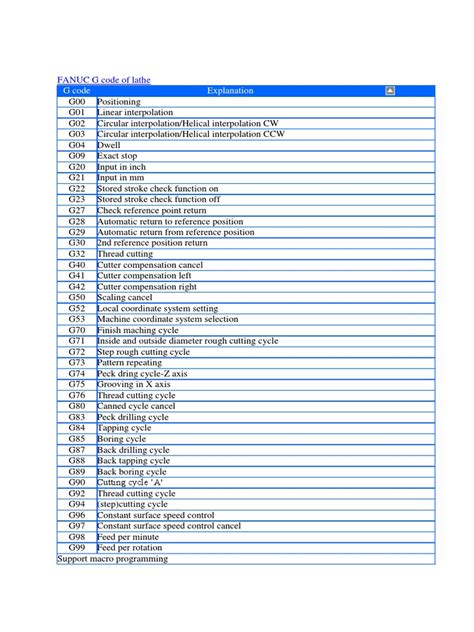

0 · fanuc g code list lathe

1 · cnc turning g code list

2 · cnc machine g code list

3 · cnc lathe programming g code

4 · cnc lathe g codes list

5 · cnc lathe g code examples

6 · cnc lathe bearing programming code

7 · cnc code list

If you just need outlets, i.e. not mounting a tv to the box, you can use a box similar to the following: Since the coax is going in the open side you don't need to worry about getting the coax to go through the clamps or the .

Jun 26, 2024

In this blog post, an experienced mechanical engineer shares insider tips and techniques for mastering Fanuc CNC lathe commands. Discover how to optimize your CNC programming skills, boost productivity, and take . CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus . Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF .I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in . These are the common g-codes for CNC Lathes and turning. Code categories are the groupings for the g-code Wizard (type Ctrl+G for the Wizard).

fanuc g code list lathe

In this blog post, an experienced mechanical engineer shares insider tips and techniques for mastering Fanuc CNC lathe commands. Discover how to optimize your CNC programming skills, boost productivity, and take your machining projects to the next level. G00 : Quick Point Positioning. G00 X__Z__ G01: Linear Interpolation. G01 X__Z__F__ CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and . Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.

I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. Whether you’re programming a chamfer or a radius, setting up a Haas or Fanuc CNC lathe, or writing a program for turning, these G-codes are your foundation. And remember, while learning the CNC lathe program, practice is key – so don’t shy away from using a CNC lathe program simulator to sharpen your skills without the risk.

CNC lathe programming is the process of creating a set of coded instructions that control a CNC lathe machine. This programming is essential for the machine to perform precise operations automatically.

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in . These are the common g-codes for CNC Lathes and turning. Code categories are the groupings for the g-code Wizard (type Ctrl+G for the Wizard). In this blog post, an experienced mechanical engineer shares insider tips and techniques for mastering Fanuc CNC lathe commands. Discover how to optimize your CNC programming skills, boost productivity, and take your machining projects to the next level. G00 : Quick Point Positioning. G00 X__Z__ G01: Linear Interpolation. G01 X__Z__F__ CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. Whether you’re programming a chamfer or a radius, setting up a Haas or Fanuc CNC lathe, or writing a program for turning, these G-codes are your foundation. And remember, while learning the CNC lathe program, practice is key – so don’t shy away from using a CNC lathe program simulator to sharpen your skills without the risk.

cnc turning g code list

Produce large parts up to 2m*2m. 2. Dimension tolerance and geometric tolerance as per ISO2768. 3. Perfect for one-off order to less than 100 pieces production. 4. Multiple fabrications combined by milling, turning, stamping, welding, etc. 5. Various surface treatments, like anodizing, oxidizing, plating, etc. 6.CNC turning excels at producing cylindrical or axially symmetrical parts with precision and efficiency. Common parts manufactured using CNC turning include shafts, pins, bushings, and connectors.

cnc lathe machine programming codes|cnc code list