how to weld stainless steel sheet metal Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), . This white brick house metal roof combination illustrates the versatility of metal roofing. The white stone facade and red brick work well with this black metal roof that looks like typical shingle roofing from a distance.

0 · welding type for stainless steel

1 · welding stainless to galvanized steel

2 · weldability of 304 stainless steel

3 · stainless steel welding problems

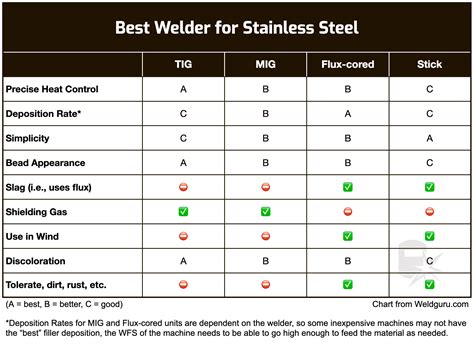

4 · stainless steel welding chart

5 · interpass temperature for stainless steel

6 · best stainless steel for welding

7 · 304 stainless steel welding procedure

There are 4 books in this series. Select the number of items you want to purchase. Coming of age can be hard for anyone. But for Blackmon Perry Stone it is life threatening. At 15, he barely manages to graduate from the empire’s cadet training by a talent for unusual problem solving.

Stainless steel can be welded using any arc welding process such as MIG, TIG, Stick & Flux-cored. Each process will yield a slightly different result and will require some learning and skill to accomplish.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), .How To MIG Weld Stainless Steel: A Beginners Guide. By: Jeff Grill. Last . How do you weld stainless steel? There are many methods of welding stainless steel, including MIG, GTAW, TIG, and stick welding. There .We’ll include an overview of preparation, filler metals, types of stainless steel, tips and tricks for the three methods, and then round things out at the end with our recommendation for the .

How To MIG Weld Stainless Steel: A Beginners Guide. By: Jeff Grill. Last updated: Jan 4, 2024. You may have many projects in mind that need to use stainless steel in their .The most commonly used welding process when working with stainless steel is TIG welding. Since this welding process has a very low input of heat, it is ideal for thin materials like stainless. This is important because stainless steel will .

welding type for stainless steel

Unlock the secrets to welding stainless steel. From expert tips to essential tools, we guide you through every step of your welding journey. Use the correct welding procedure and parameters for the specific grade of stainless steel. Use a suitable stainless steel filler wire that matches the base metal. Maintain proper shielding gas coverage to prevent oxidation and . To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet .

The optimal method for welding stainless steel depends on factors such as the stainless-steel grade, thickness, and intended application. Generally, TIG welding (GTAW) is often considered one of the best approaches due to its . Gas welding sheet metal is a great way to join two pieces together quickly and efficiently without having to rely on traditional methods such as soldering or brazing. With the right tools and know-how, however, anyone can .For stainless 316 use 316 filler, for stainless steel 304 use 308 filler metal, for carbon steel use 309 filler metal. Shielding gas is used to protect the weld from contaminants with the basic idea of having more argon in the mixture. If you . Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

MIG stands for Metal Inert Gas, and it is a welding process that uses a wire electrode and a shielding gas to join two pieces of metal together. . MIG welding stainless steel can be challenging for beginners due to its unique properties. However, with proper preparation, equipment, and technique, it is possible to achieve successful welds. .

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. Hello everyone.Today I butt welded a thin stainless steel plate with a thickness of 1mm.A few tips and tricks for welding thin sheets are included in the vid.It is tough difficult to weld thin sheets of stainless steel especially using stick welding, a lot of people seem to struggle with anything less than 2mm/ 12 gauge in thickness. . It works best with thicker pieces of metal. You can use stick welding with everything ranging from stainless steel to cast iron, chrome, and nickel-based alloys .When it comes to welding stainless steel, the task is not as easy to handle as it is with welding carbon steel. It’s a critical skill that welders can gain over time with plenty of practice and experience. However, one of the major challenges when welding stainless steel is the potential for warping during the welding process.

Everlast Ambassador @blak_widow_welder is going to use the Everlast PowerPro 164i to show you how to avoid distortion when TIG welding stainless steel.The Ev. Best Practices for Welding Stainless Steel. Welding stainless steel requires careful attention to detail to ensure strong, corrosion-resistant welds. Here are some best practices to follow when welding stainless steel: 1. Select the Right Filler Material: Choose a filler material that matches or closely resembles the base stainless-steel alloy .

Today, I am excited to share my thoughts on spot welding stainless steel, an essential skill in our industry. Spot welding stainless steel involves using high currents through electrodes to fuse metal sheets. We use spot welding to create localized, strong welds. This method is quick and efficient, perfect for stainless steel.Using the DHC2000 oxygen and acetylene welding and cutting torch to gas weld thin steel.Most people are not familiar with this weld method. When it comes to welding light gauge sheet metal, most would prefer TIG. TIG welding is a very slow proce. Before you begin stick welding stainless steel, it’s important to properly set up your welding machine. Here’s a step-by-step guide: Set the amperage: Adjust the amperage to the recommended range for the electrode you’re using. Refer to the electrode packaging or consult the manufacturer’s guidelines for the appropriate amperage range.

Avoid over welding your metals. It is tempting to over weld your metals with the aim of making them stronger but this only increases your chances of getting more distortions. The rule is the more metal you place on a joint the more the weld .

In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . If you’re looking to weld two pieces of metal together, it’s important to understand how these materials behave and which techniques will best suit your project. Let’s look at what you need to know about welding steel to .

https://www.proshaper.comOur Amazon Storefront:https://www.amazon.com/shop/proshaperIn this video Wray shows the steel sheet metal butt welding results after.Welding Stainless Steel and Aluminum. Challenges and Considerations for Stainless Steel. Welding stainless steel can be challenging due to its tendency to warp and high thermal conductivity. Proper heat control and using a backing gas can help mitigate these issues. Techniques for Welding Aluminum Sheet Metal

Method 1: Argon arc welding of thin stainless steel sheet: No welding wire is required during welding, and the base metal fused by itself.Therefore, the quality of stainless steel sheet welding is closely related to factors such as operators, equipment, materials, construction methods and external environment during welding.

The best way I have found to tack weld stainless steel sheet metal is: • Make sure the fitup is tight with absolutely no gap • Prop your tig cup right on the joint with the sharp tungsten electrode tip less than 1/16” from the joint

It is appropriate to describe the procedure first for welding stainless steel. Before commencing weld metal deposition, the surface needs to be adequately cleaned of contaminants such as grease or rust. Wire additions cut to size, typically ER308L wire, are available to weld 304 stainless steel to maintain strength and corrosion in the welded . The filler metal is heated at a temperature of over 800 degrees. While this method is like welding, it’s less costly. Plus, it’s more like using an adhesive rather than melting the metal pieces themselves. For this reason, we still consider it a method to bond metal to metal without welding. How to Bond Metal To Metal With Brazing Welding of stainless steel sheets 0.8 min. Stainless and carbon steel can be welded, but there is one common mistake that is made over and over.VISIT OUR SITE: https://www.weld.comFOLLOW US ON INST.

Are you looking to improve your MIG welds on stainless steel? From properly cleaning the base metal to using the right welding technique and consumables for .In this video we go through the process of welding, grinding, and polishing an outside corner weld. We are tig welding the stainless steel sheet metal then .

welding stainless to galvanized steel

PPs can be converted into ceramics through a controlled heat treatment. In polymer derived ceramics (PDCs), the polymer is first shaped, followed by crosslinking or gelling, and finally converted into a ceramic component through pyrolysis at .

how to weld stainless steel sheet metal|best stainless steel for welding