processing of sheet metal parts foreign trade parts. Two new concepts that emerge from the Mod Act are “informed compliance” and “shared responsibility,” which are premised on the idea that in order to maximize voluntary compliance . $135.00

0 · types of sheet metal operations pdf

1 · sheet metal shearing process

2 · sheet metal shearing operations

3 · sheet metal process

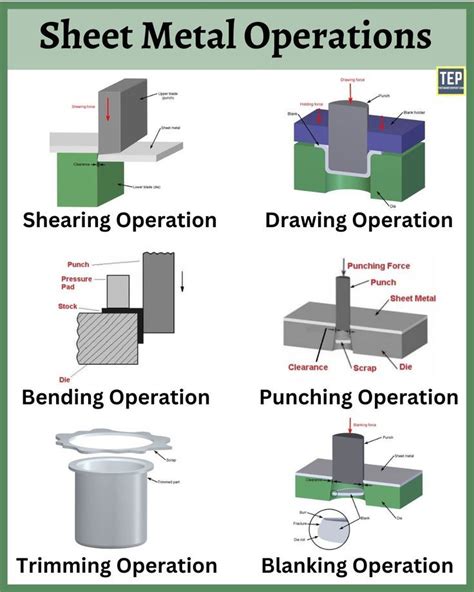

4 · sheet metal operations diagram

5 · sheet metal operations

6 · sheet metal forming methods

7 · sheet metal fabrication process

$532.00

The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes .

Two new concepts that emerge from the Mod Act are “informed compliance” and “shared responsibility,” which are premised on the idea that in order to maximize voluntary compliance .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .The company is located in the beautiful coastal city - China Weihai. The company has first-class processing equipment and strong financial and technical strength, the company has laser plate cutting machine, CNC laser cutting machine, CNC bending machine welding robot CNC machining center is set production and trade in one of the company, the factory covers an .

Foreign trade circle rules related to metal parts. COKO HARDWARE CO.,LTD +8615798481604; COKO HARDWARE CO.,LTD; ISO 9001: 2010; CNC products manufacturer; and solution provider; Shenzhen, Guangdong, China 518100; Home; .

Custom Sheet Metal Parts with Laser Cutting Bending Stamping Service Punch Processing Sheet Metal Fabrication, Find Details and Price about Sheet Metal Fabrication Punch Processing from Custom Sheet Metal Parts with Laser . Now that each laser feeds more parts to more downstream machines, strategic part identification and sorting has become more important than ever. Measure What You Have. You send a nest to the laser to be scheduled among that day’s job list. The parts are cut, sorted, then sent downstream or stored as work-in-process (WIP) inventory.The company mainly produces various mechanical spare parts: Metal parts processing, sheet metal, metal structure, titanium alloy, superalloy, non-metal and other mechanical processing . As a traditional industrial and trade company, we have a complete corporate functional system of personnel, finance, technology, logistics and business .

7. Sheet metal and stamping Sheet metal fabrication involves cutting parts from sheet metal. The blanked sheet can then be machined by means of brakes and die presses to create angled bends and shapes to build 3-dimensional structures. Sheet metal services feature metal stamping to quickly produce these parts. In fact, stamping is faster than . Sell your Sheet Metal Parts products to global buyers for Free. There are currently 83 Sheet Metal Parts international importers waiting to connect with suppliers on Tradewheel.com. . Aluminum Stamping Process Custom Steel Metal Thin Sheet Metal Stamped Sheet Parts Sheet Metal. I am reaching out to get quotes on three parts (drawings attached .

For example, parts used in aerospace might have different codes compared to those used in general construction. Always take these details into account. Common HTS Codes for Sheet Metal Fabricated Parts. Here are some HTS codes commonly used for sheet metal fabricated parts: HTS 7308.90: Other structures and parts of structures, of iron or steel

1.1. Principle of stamping-forging processing (SFP) for sheet metal. SFP is a combined metal forming technology of stamping and forging for sheet metal parts. In an SFP, generally, stamping or drawing is used to form the spatial shape of thepart first, and followed by a bulk forming employed to form the local thickened feature.🌟 Sheet Metal Processing Industry Overview 🌟 Sheet metal processing is increasingly vital due to innovations in automotive, IT, and everyday hardware. This.Chemical Metal Supplier, Chemical Metal Manufacturers/ Suppliers - Shaan Foreign Trade (Shanghai) Co., Ltd.The right tricks allow you to design your parts more cost-effectively. The solution: Reducing the number of single parts and process steps. The support bracket shown here originally consisted of three parts connected with four weld seams, plus separately cut threads. It was redesigned out of just one bending part – without welding.

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies. In this article .

types of sheet metal operations pdf

Sheet metal fabrication is ideal for producing parts with complex geometries, especially those that require bends, flanges, or complex cuts. The process is highly flexible and can create prototypes, small batches, or large-scale production. However, the accuracy achievable with sheet metal parts can be relatively low compared to machined parts.

1.1. Principle of stamping-forging processing (SFP) for sheet metal SFP is a combined metal forming technology of stamping and forging for sheet metal parts. In an SFP, generally, stamping or drawing is used to form the spatial shape of the part first, and followed by a bulk forming employed to form the local thickened feature. It is suitable Designing sheet metal parts in CAD—for reality . gap between engineers and manufacturers. venimo / iStock / Getty Images Plus. Engineering is all about constraints and trade-offs. For any given problem, there’s an infinite universe of possible solutions. . Manufacturing brokers simplify the ordering process in some ways. They use .Buy sheet metal parts in bulk online from 56 verified wholesale sheet metal parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources. . parts sheet metal processing. . buyers will immediately recognize the hot-selling product categories, MOQ demands, overseas-trade market, and company size of .

Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate steel or "structural steel".

Fabrication Sheet Metal Parts for Air Conditioning. Fabrication Sheet Metal Parts for Air Conditioning 1. We are ODM&OEM, design according to your drawing. 2. Rich experience and good technology support( have engineers with more than 20 years experience). 3. Manufacturer and Trade Company. 4. Low MOQ is accepted. 5. 100% inspection. In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsDiscover the top China manufacture of Metal Processing Machinery Parts, serving supplier and wholesale needs. . Metal chassis, metal cabinets, metal cases, metal enclosures, metallic auto parts,sheet metal parts, OEM mold design and fabrication MATERIAL AVAILABLE Carbon steel (CRS/SPCC, SECC,etc),stainless steel, spring steel, Bronze .SUS304 Stainless Steel Sheet Metal Stamping Parts for Moto Shell. . OEM Brass/Copper/Bronze CNC Machining Bicycle Parts with CNC Metal Processing. ISO 9001 Qualified OEM Machining Steel Machinery Equipment Parts. . Weifang Jufeng International Trade Co.,Ltd. .

The way metal parts are made can vary greatly. Each process has its own advantages, compatible materials and trade-offs. A better understanding of the scope of production methods will improve this decision-making process. This is an overview of eight different manufacturing processes that can be used to create custom metal parts. These are: Because the profile tolerance is widely used in the BIW sheet metal parts as the manufacturing requirements for the single parts as well as the assemblies to ensure the dimensional quality of the product, this type of tolerance on parts are mapped on the FE meshes in this work subjected to the Product Manufacturing Information (PMI .481 Trade Shows related to Metal Working Industries; Exhibition Name Cycle Venue Date; IMT – INTERNATIONAL METAL TECHNOLOGYInternational Metal Tecnology Trade Show.Metallurgy technology, Foundry machinery, equipment and supplies, Semi-finished & finished products, Thermo process technology, Accessories & components, Tubes, Metal cutting machine Tools.

When it comes to customized metal parts manufacturing, Sinoway is absolutely the right-matched option. We are in the business of supplying one-stop manufacturing services and creating value for customers by OEM manufacturing quality metal parts . Quotable Sheet Metal Post Processing & Finishing / / Post processing and finishing can improve the overall quality of a part while also ensuring the part meets design specifications. To customize or finish a part, smoothing or painting are often required. . Sheet metal parts can be screen printed in a variety of different finishes and colors .

sheet metal shearing process

$7,250.00

processing of sheet metal parts foreign trade parts.|sheet metal operations