design for manufacturing cnc Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

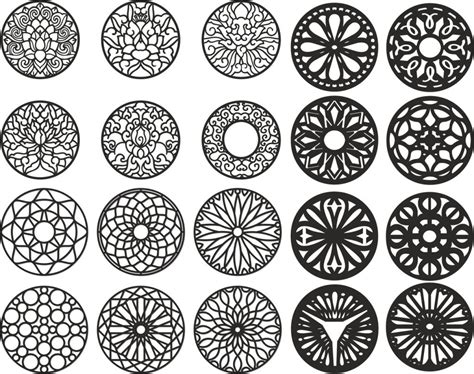

0 · free printable cnc patterns

1 · designs for cnc machine

2 · designs cnc free download

3 · cnc templates and designs

4 · cnc patterns adult

5 · cnc designs download

6 · cnc design website

7 · cnc design sheet

There are many methods of welding stainless steel, including MIG, GTAW, TIG, and stick welding. There are advantages and disadvantages of .

Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project.Design for CNC machining. In less than 15 minutes, you will learn all you need to .Design for manufacturing (DFM) means taking a design-first approach to .

Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface .

Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations.Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts.

CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to foam and metal. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Design for Manufacturability (DFM) is more than just a buzzword; it’s a systematic approach that bridges innovative concepts with practical manufacturability in CNC machining. Here’s a step-by-step guide on how to seamlessly integrate DFM principles into CNC designs: The journey begins with a comprehensive evaluation of the initial design.Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

Here’s a short list of design factors to prioritize for CNC machinability. CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to .

free printable cnc patterns

Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components. When designing parts for CNC machining, it’s essential to keep the DFM principles in mind. These principles are based on the idea of designing parts that are easy to manufacture, and they can help you to avoid common pitfalls and ensure that your parts are optimized for CNC machining. Some of the key DFM principles to keep in mind include:

electric junction box production line suppliers

Make the most of CNC machining by optimizing your design and making the right material choices. Read these 14 design tips to help you reduce CNC-machining costs and create the perfect parts for your project.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations.Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts.

CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to foam and metal. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Design for Manufacturability (DFM) is more than just a buzzword; it’s a systematic approach that bridges innovative concepts with practical manufacturability in CNC machining. Here’s a step-by-step guide on how to seamlessly integrate DFM principles into CNC designs: The journey begins with a comprehensive evaluation of the initial design.

designs for cnc machine

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.Here’s a short list of design factors to prioritize for CNC machinability. CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to .

Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components.

designs cnc free download

electric humidifier for cigar box

electric heating lunch box portable

I've been looking for a decently priced AC capable TIG machine, and came across a Lincoln Square Wave TIG 175. My TIG machine for the last several years has been a Lincoln Invertec V-250s, which is a DC only machine.

design for manufacturing cnc|designs cnc free download