precision sheet metal tolerances Tolerances for laser cutting, water jet cutting, forming, weldments, etc. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu

[email protected] (916) 419-0580; Services. . Precision Sheet Metal Fabrication Request a Quote. Microform Precision, LLC 4244 South Market Court, Suite A Sacramento, CA 95834 Phone: (916) 419 . $8.99

0 · typical sheet metal tolerances

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm steel sheet tolerance chart

BUILDINGS . 3 total 45000 sq. ft. PUNCHING. 1 Amada Vipros 255, 31 .

Tolerancing in precision sheet metal fabrication is more complex due to two key factors: raw materials and manufacturing processes. Unlike .

Unlock the secrets to mastering sheet metal tolerances and ensure precision in your manufacturing processes. Explore the key factors that contribute to top-notch engineering results.Tolerances for laser cutting, water jet cutting, forming, weldments, etc. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu [email protected] (916) 419-0580; Services. . Precision Sheet Metal Fabrication Request a Quote. Microform Precision, LLC 4244 South Market Court, Suite A Sacramento, CA 95834 Phone: (916) 419 .

This synergy between design precision and fabrication reality underscores the essence of optimal tolerance in sheet metal manufacturing, ensuring quality, functionality, and cost efficiency. . Laser cutting is a favored .

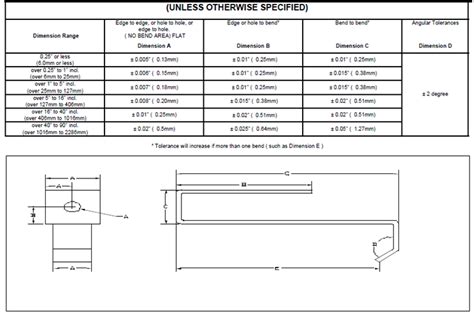

I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you need. . If that means machining something on the bent leg after forming, that's better than depending on the brake for precision. Also, verify your CAD bend radius . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .General Dimensional Tolerances. Dimension Range. DIM ≤ 8″ [203mm] 8″ [203mm] < DIM ≤ 16″[406mm] 16″[406mm] < DIM ≤ 36″[914mm] Edge to Edge, Hole to Hole, . Pinnacle’s expert Production crew utilizes 14 press brakes while forming precision sheet metal parts for our customers. Our collection of brakes and tools ensures we .Pinnacle’s production floor boasts a handful of precision CNC laser cutting machines and experienced sheet metal professionals that help set every manufacturing run up for success. Our team is focused on accuracy while cutting to the tightest .

Where precision meets the whimsy band. In the workshop, parts take their birth, On a press brake, bending metal’s worth. But Murphy sneaks in, with his grin, And brings a twist to the design within. Dimensions off by a hair so small, A metal sheet, once straight, takes a fall. Tolerances tested, designs redrawn, Murphy’s pranks go on and on. Precision sheet metal fabrication accurately produces detailed and ready-to-use parts for prototype to high-volume manufacturing with exact measurements. Services. Machining Service. . Metals must fit precisely and high tolerance means that highly detailed metal parts are fashioned. Because state-of-the-art technology is exploited and as a .

Understanding and Applying Tolerances for Sheet Metal Bending Processes Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. . the machined geometry is mostly controlled by the precision of movements of the cutting tools. Other factors make much less contribution to the final precision .

typical sheet metal tolerances

steel plate thickness tolerance chart

prov3 toolings and metal fabrication

Last updated on June 4th, 2024 at 02:13 pm. It’s no mystery why powder coating is such a popular choice for precision sheet metal finishing.This process is incredibly durable, provides a consistent and attractive finish, and is available in over 6,500 colors and a variety of textures. One of the only drawbacks to powder coating is that it adds a slight amount of . 1 Recommended Default Sheet Metal Tolerances; 2 Approved Sheet Metal American Made Parts FAQ. 2.0.1 Why should I choose American-made sheet metal prototyping over overseas options? 2.0.2 Is local manufacturing more expensive compared to overseas resources? 2.0.3 What are the advantages of choosing domestic manufacturing for sheet .Generally speaking, +/-.003″ is a reasonable and functional tolerance. Hole to Hole. Accuracy of the distance from one hole to another is dependent primarily upon the machinery used to process the sheet. However, all holes and features punched through the sheet can introduce stress into the sheet metal.

Partnered with Pinnacle’s Technical and Production crew, these machines allow us to punch a variety of sheet metal grades to the tightest tolerances. (2) CNC Turrett Presses with 60” X 100” stock size capacity and 40 tool stations . Pinnacle Precision Sheet Metal 5410 E. La Palma Ave. Anaheim, CA 92807. 714-777-3129. Linkedin .Perfolux has earned a worldwide reputation for precision metal fabrication and precision sheet metal punching, manufacturing components to meet the most exacting tolerances. Our metal fabrication facilities are equipped with automated machinery .Sheet Length Up to 144″ Sheet Width Up to 60″ Tolerances ±0.005″ Typical Tighter Tolerances Held According to Specifications Materials Acrylic Aluminum (All Alloys) Armor Plate Brass Bronze Copper Expanded Metal G10 .

Mastering Laser Cutting Tolerance: Ultimate Precision and Limitations Guide (2024) October 2, 2024; No Comments . Fibre lasers, on the other hand, do a better job of cutting sheet metal because they have more . 3 Recommended Default Sheet Metal Tolerances; 4 Fiber Laser Advantages for Sheet Metal Fab FAQ. 4.0.1 What is a Fiber Laser and How Does It Differ from CO2 Laser Cutting? . Precision Sheet Metal Fabrication, Sheet .

Calculates the tightest GD&T position tolerance for a hole that Microform Precision can hold. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu [email protected] (916) 419-0580; . Precision Sheet Metal Fabrication Request a Quote. Microform Precision, LLC 4244 South Market Court, Suite A Sacramento, CA 95834 Phone .

What’s considered a “standard” tolerance differs in precision machining and sheet metal fabrication. A standard tolerance for precision machined parts is +/- 0.005.” A standard tolerance for sheet metal fabricated parts is much looser, ranging from +/- 0.02” to +/- 0.03.” Tolerances can also vary within parts.Specialize in CNC Milling, CNC Turning, 3D Printing, Urethane Casting, and Sheet Metal Fabrication Services. LinkedIn; . Tight tolerances lead to higher precision but often increase the cost and complexity of the machining process. On the other hand, looser tolerances may reduce costs but can compromise the functionality of the machined parts. Sheet Metal Tolerances. Many engineers misunderstand sheet metal tolerancing—and for a good reason. Engineering curriculums are often skewed toward CNC machining and 3D printing, leaving engineers with a gap in understanding when it comes to sheet metal fabrication. Tight tolerances such as +/- 0.002" are the norm in machining. But with sheet .

3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Finishes FAQ. 4.0.1 What are the different classes of sheet metal finish? . Follow us to learn about everything that is Precision Sheet Metal Fabrication. LinkedIn; Facebook; YouTube; Google Reviews. 4.9 Stars - Based on 89 Customer Reviews. Approved Sheet Metal 2 Sheet Metal Hardware Hole Sizes Chart. 2.1 CHART DOWNLOAD; 3 Choosing the Right Hardware for Your Precision Sheet Metal Fabrication; 4 Precision Sheet Metal Hardware FAQ. 4.0.1 What are the common types of hardware used in precision sheet metal fabrication? 4.0.2 How do PEM nuts differ from other fasteners in the industry? Precision is paramount in aerospace sheet metal fabrication, as the intricate components must adhere to strict tolerances and quality standards to ensure the structural integrity and reliability of the final products.Standard Tolerances in Precision Sheet Metal. Standard Tolerances in Precision Sheet Metal. June 8, 2020 11:49 pm. You spent thousands on a new precision sheet metal machine and researched the best machine for your needs. However, there are still inconsistent bends and angles. This could occur for several reasons but tolerance is often the cause.

Precision sheet metal fabrication presents its own set of challenges when it comes to tolerancing, distinguishing it from precision machining. To truly grasp and navigate the complexities of sheet metal tolerances, it is crucial to understand the .

Explore the art of Precision Sheet Metal Fabrication with Zetwerk and gain a deep understanding of achieving perfection in metal works. . aluminum, copper, brass, and other metals. There are +/-.003″-.007″ tolerances. Welding: A clean, robust, and exact joint can be created between two metal parts by welding. Welding processes include Gas .

pt. mmc metal fabrication

standard sheet metal tolerances chart

$4.36

precision sheet metal tolerances|steel plate thickness tolerance chart