bottoming in sheet metal From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the . Built with a strong and durable steel frame and a versatile poly jacquard cover that slips right on, the Smart BoxSpring® is the picture of dependability for any mattress. All packed in a compact shipping box with everything included, even our 5-year worry free warranty! Now that’s peace of mind you can sleep on. Dimensions: Weight Capacity:

0 · sheet metal bottom bending angle

1 · sheet metal bending processes

2 · sheet metal bending problems

3 · sheet metal bending directions

4 · sheet metal air bending vs bottom

5 · partial bending sheet metal

6 · bottom pressing sheet metal

7 · bottom bending sheet metal

ฉนวนพียู เป็นวัสดุป้องกันความร้อน ช่วยกันความร้อนได้ถึง 90% จะช่วยป้องกันการเเผ่กระจายความร้อนจากหลังคาเข้าสู่ตัวอาคาร .

Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.Air bending is called air bending because a gap is left between the sheet metal .

Air bending is called air bending because a gap is left between the sheet metal being bent and the bottom tool when the sheet metal is at its full bend depth. Bottom bending also uses a punch .Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles. From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the .Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In .

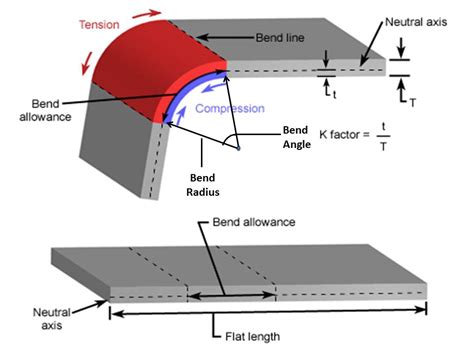

Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material.

Bottoming and coining are more precise bending techniques. In bottoming, the sheet metal is pressed against the die until it conforms to its shape, resulting in more accurate bends. Coining involves applying enough pressure to imprint .

Bending is a common metalworking operation to create localized deformation in sheets (or blanks), plates, sections, tubes, and wires. This article emphasizes on the bending of sheet . Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable. Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece.

Bottom bending—commonly called “bottoming”—compresses the sheet metal to the bottom of the die to create the desired shape and angle. The shape and position of the die angle determine the final shape of the bend.Air bending is called air bending because a gap is left between the sheet metal being bent and the bottom tool when the sheet metal is at its full bend depth. Bottom bending also uses a punch and bottom v-shaped die in a brake press.

Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.

From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the bending method still permeates our thinking when we bend sheet metal.Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In this, the .

Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material.Bottoming and coining are more precise bending techniques. In bottoming, the sheet metal is pressed against the die until it conforms to its shape, resulting in more accurate bends. Coining involves applying enough pressure to imprint the die's shape into .

Bending is a common metalworking operation to create localized deformation in sheets (or blanks), plates, sections, tubes, and wires. This article emphasizes on the bending of sheet metal along with some coverage on flanging. Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.

sheet metal bottom bending angle

Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece.Bottom bending—commonly called “bottoming”—compresses the sheet metal to the bottom of the die to create the desired shape and angle. The shape and position of the die angle determine the final shape of the bend.Air bending is called air bending because a gap is left between the sheet metal being bent and the bottom tool when the sheet metal is at its full bend depth. Bottom bending also uses a punch and bottom v-shaped die in a brake press.Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.

From the advent of the powered press brake in the 1920s to the present day, operators have formed parts with bottom bending, or bottoming. Even though bottoming has been losing favor over the last 20 to 30 years, the bending method still permeates our thinking when we bend sheet metal.Bottom Bending or Bottoming in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. But punch and die do not make complete contact with sheet metal. In this, the . Sheet metal bending methods are those in which force is applied to a piece of sheet metal causing it to bend at a given angle to create a desired shape rather than remove any material.Bottoming and coining are more precise bending techniques. In bottoming, the sheet metal is pressed against the die until it conforms to its shape, resulting in more accurate bends. Coining involves applying enough pressure to imprint the die's shape into .

engine gearbox mount bracket

enlarging electrical switch box in wall

Shop this Zvex Box of Metal high-gain effect pedal today. Overview:The Box of Metal (tm) is an aggressive high-gain pedal with a highly-effective built-in switchable gate which dramatically reduces noise and unwanted feedback.This model is no longer being manufactured.

bottoming in sheet metal|sheet metal air bending vs bottom