cnc cavity processing manufacturer Our state-of-the-art CNC machining capabilities enable us to produce complex and intricate parts with high precision and accuracy, ensuring the highest quality standards.

The most common causes for a burning smell in your house are burnt food, dust on the furnace, and clogged air ducts. A burning smell can also spread throughout your house if you constantly run a space heater or if it is dirty.

0 · CNC Machining for Large Cavities: Techniques and Tips

1 · Americas Manufacturing Group LLC

As one of the leading titanium cnc machined parts manufacturers and suppliers in China, we warmly welcome you to wholesale hot sale titanium cnc machined parts made in China here from our factory. All customized products are with high quality and low price.

Our state-of-the-art CNC machining capabilities enable us to produce complex and intricate parts with high precision and accuracy, ensuring the highest quality standards.

Contact - Americas Manufacturing Group LLCAbout - Americas Manufacturing Group LLCTeam 1 - Americas Manufacturing Group LLC Large cavity CNC machining stands out as a pivotal technology that allows manufacturers to create intricate geometries, ensuring that components fit perfectly in various.

Our state-of-the-art CNC machining capabilities enable us to produce complex and intricate parts with high precision and accuracy, ensuring the highest quality standards. Large cavity CNC machining stands out as a pivotal technology that allows manufacturers to create intricate geometries, ensuring that components fit perfectly in various.

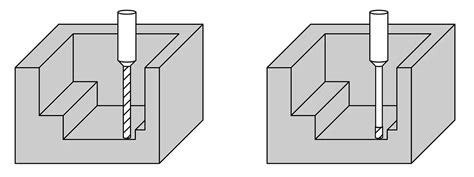

CNC Machining for Large Cavities: Techniques and Tips

This article offers a comprehensive guide to CNC machining of deep cavity and thin-wall parts. It addresses definitions, challenges, and best practices, including design, strategies, tool selection, material prep, and quality control. By understanding the benefits and process of CNC machining of cavity shells, manufacturers can create high-quality components that meet the demands of modern industries. Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.Xavier is a global precision non-standard parts manufacturer. Its products include CNC machining, five-axis machining, die casting, casting, forging, etc.

Our mold cavity machining services offer unmatched precision and efficiency for replicating products flawlessly. With advanced equipment, expert craftsmanship, and a collaborative approach, we deliver industry-leading solutions tailored to your unique speLooking for a reliable, quick-turn supplier of machined steel, aluminium, titanium and metal components? Our CNC machining facility is designed for large dimension and low-volume production of end-use components. Deep-cavity machining in CNC manufacturing is a cutting-edge process that brings precision, complexity, and durability to industries that demand it. From aerospace and automotive to medical devices, it plays a vital role in making components that power our world. We have ranked the top 10 world’s best CNC machine manufacturers & brands by researching data from Google based on business sizes, technical capabilities, revenues, customer reviews and ratings, including Mazak, Trumpf, DMG MORI, MAG, Haas, Hardinge, AMADA, Okuma, Makino, EMAG, which are located in Japan, Germany and the United States.

JITO is a professional casting product, forging part, and custom CNC machining manufacturer. We provide OEM metal machining services and export trade globally. Please contact us for more info.

Our state-of-the-art CNC machining capabilities enable us to produce complex and intricate parts with high precision and accuracy, ensuring the highest quality standards. Large cavity CNC machining stands out as a pivotal technology that allows manufacturers to create intricate geometries, ensuring that components fit perfectly in various. This article offers a comprehensive guide to CNC machining of deep cavity and thin-wall parts. It addresses definitions, challenges, and best practices, including design, strategies, tool selection, material prep, and quality control. By understanding the benefits and process of CNC machining of cavity shells, manufacturers can create high-quality components that meet the demands of modern industries. Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.

Xavier is a global precision non-standard parts manufacturer. Its products include CNC machining, five-axis machining, die casting, casting, forging, etc.Our mold cavity machining services offer unmatched precision and efficiency for replicating products flawlessly. With advanced equipment, expert craftsmanship, and a collaborative approach, we deliver industry-leading solutions tailored to your unique spe

Looking for a reliable, quick-turn supplier of machined steel, aluminium, titanium and metal components? Our CNC machining facility is designed for large dimension and low-volume production of end-use components. Deep-cavity machining in CNC manufacturing is a cutting-edge process that brings precision, complexity, and durability to industries that demand it. From aerospace and automotive to medical devices, it plays a vital role in making components that power our world. We have ranked the top 10 world’s best CNC machine manufacturers & brands by researching data from Google based on business sizes, technical capabilities, revenues, customer reviews and ratings, including Mazak, Trumpf, DMG MORI, MAG, Haas, Hardinge, AMADA, Okuma, Makino, EMAG, which are located in Japan, Germany and the United States.

Americas Manufacturing Group LLC

Jennings says his house survived the Valley Fire of 2015 because it was not made of wood. When he’d built it five years earlier, Jennings instead used something called RSG 3-D panels—blocks of.

cnc cavity processing manufacturer|CNC Machining for Large Cavities: Techniques and Tips