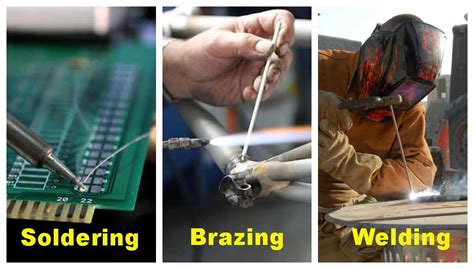

how to braze weld sheet metal Brazing is the process of joining two independent pieces of metal to form one strong load-bearing joint. Brazing is similar to soldering, but at higher temperatures. Use the right brazing rod material for the metal used in your . Be confident using authentic Carlon® Blue™ electrical solutions, which are extensively tested to meet code and deliver reliable and safe power. Look for Carlon® branded electrical boxes, fittings and accessories at retailers and electrical distributors.

0 · what is brazing vs welding

1 · how to braze metals together

2 · how to braze galvanized pipe

3 · examples of brazing

4 · can you weld over brazing

5 · brazing vs soldering welding

6 · brazing for beginners

7 · braze welding vs brazing

Choosing between CNC machining and 3D printing for your prototyping needs depends on the specific requirements of your project. 3D printing offers rapid, cost-effective solutions for complex and iterative designs, while CNC machining provides high precision, material versatility, and superior surface quality for functional prototypes.

To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as goggles and gloves.One of the most popular and effective ways of joining steel is through brazing .

To braze weld thin metal, you need to use a low-temperature brazing rod and a .Brazing is the process of joining two independent pieces of metal to form one strong load-bearing joint. Brazing is similar to soldering, but at higher temperatures. Use the right brazing rod material for the metal used in your . One of the most popular and effective ways of joining steel is through brazing welding. This process involves using a torch to heat the joint and applying a filler metal to connect two pieces of metal. Unlike other welding .

I was planning to grind the area around the hole to bare metal, take a sheet metal patch and use a hammer to get the patch to conform to the body of the car, probably put in a few screws to hold the patch in place, and then braze. That is probably 20 or 21 gage material, from that measurement. Keep in mind that when mig welding, if there is a gap between the pieces, when lap welding, you can easily burn thru. You should get some pieces of the same thicknesses and practice to get the welder set-up, and used to welding it, before trying on the vehicle.

Welding holes in thin metal or sheet metal is a crucial skill. Whether you're correcting a mistake or shaving a body so it's perfectly smooth this skill will.

basics of how to solder using muriatic acid, cFLUX, map gas, and tri-bar solder.The seals between sheet metal panels are not watertight. I would like to braze/solder a couple of laps while preserving the galvanization. Looking for recommendations on filler, flux and tooling. I have oxy-acetylene and propane torches available. . Brazing, soldering, or welding isn't the right way to repair leaky metals roofing.

what is brazing vs welding

metal fabrication galway

We need to make some repairs on the fender for our '71 Chevy pickup project. Just for fun let's do this old school, by torch welding it. email: ratzlaffmotor. #welddotcomWe are still working through your requests that were submitted through our Instagram story. @bostonrush77 asked us to show how to do old rusty she.

Gas welding sheet metal is quickly becoming a lost art. This is due largely in part to the speed in which a MIG can produce results and the learning curve to learn to use a MIG vs. gas weld. . Braze welding on the other hand is done by heating the base metals hot enough to "Tin" the surface, (but not hot enough to melt the base metal) and . Finally, brazing fluxes have a tendency to cause hydrogen embrittlement in the metal adjacent to brazed joints, and this can cause cracking in that metal, as panels vibration cycle over miles and time. Braze welding, unlike brazing, goes beyond capillary action and deposits a strengthening thickness (or bead) of brazing material in braze weld .Sometimes, a decision to use brazing over welding results from choosing an inexpensive method over a costly one. Filler metal for brazing is cheaper than MIG or TIG electrodes. Therefore, many large-scale manufacturers prefer brazing over welding when they’re responsible for filling massive orders. Sheet metal joining is often accomplished .

The previous video I posted on brazing got enough constructive criticism, I decided to redo the audio and point out the mistakes I made while brazing.This video is just one example of brazing thin metal to thick metal. In this case it is brazing a 1/16th" mild steel rod to a piece of 1/8th x 1" mild steel.

metal fabrication findlay ohio

Braze flux is corrosive ( that is how it cleans the metal ) , if any flux is left over the metal will rust. Add in a torch flame oxidizes the metal a bit and you have every reason why MIG is so much better on automotive sheetmetal. Brazing is good for small areas that need "glued " together to reduce the chances of cracking.Explanation: Here I show you how to braze steel with all safety precautions included. Hopefully will show how braze aluminium soon! Hi all, this is my engine. Difference Between Brazing and Welding. While both brazing and welding use heat to join metal pieces, the main difference is in the temperature needed and heat sources. Brazing takes place at temperatures above 840°F .Welding Tips and Techniques: How to Braze 3003 Aluminum. What exactly is 3003 aluminum? 3003 aluminum is a non-heat treatable alloy used primarily for sheet metal work, duct work, and chemical equipment, as well as in the .

I'm not a certified welder. I'm simply a self taught welder and thought I could pass on a tip that has helped me along the way. Pro welders probably spot wel. James shows how to braze similar metals this time. Whilst this could be achieved by welding, we wanted to show how you can also braze two metals of the same .

Have you ever wanted to make your own bumpers or tube chassis for your RC truck? Were you worried it would cost too much or be too difficult? This video is m. Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how v. Brazing is a widely used technique for joining aluminum and steel, offering several advantages over traditional welding methods. This article will explore the techniques used for brazing aluminum to steel and the advantages of brazing over other joining methods. . Porosity: If you use insufficient filler metal or the brazing temperature is .

Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. MIG Welding (GMAW) MIG welding works fine for thin materials . Welding stress fracture in sheet metal. . I would normally open up the crack and weld or braze a small piece of metal behind it to form a doubler to give added support to that area. But, due to its location I cannot increase the thickness of the metal. . but I fear the concentrated heat will embrittle the metal next to the weld causing it . Another favor for my neighbor. Trying to do the minimal amount of damage mig welding thin chrome sheet metal to fix a broken furniture leg.Best welding glove.Super Alloy 1 contains cadmium. Super Alloy 1 can easily solder galvanized steel plates together. Super Alloy 1 has a very low melting point which prevents t.

Brazing Steel Metal. Brazing exists as the best yet suitable way of joining two different steel types. It’s also ideal where you’re not looking to make a solid physical bond for aesthetics. Follow these steps on how to braze steel metal and do it with perfection: Prepare to Braze. Start by cleaning the steel to remove any dirt, oil, and grease.

1. Use braze welding electrodes. You can join thin metals with your stick welder by using braze-welding rods instead of typical rods. Braze rods are excellent at lowering the danger of damaging thin metals. They are easier to use and work faster. Braze welding rods are based on copper. They melt at a lower temperature than steel rods.

how to braze metals together

metal fabrication gate designs

In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as .

how to braze weld sheet metal|examples of brazing