lance and form sheet metal Special forms – The turret punch press offers many versatile solutions for putting special features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, . The size of screws you need for an electrical box will depend on the type of box and the thickness of the wall. For most standard electrical boxes, you will need 6 screws. If .

0 · thinning in sheet metal forming

1 · sheet metal lance stamping

2 · press forming of sheet metal

3 · lancing process in sheet metal

4 · lancing operation in sheet metal

5 · lance punch dies

6 · how to joggle sheet metal

7 · half shear sheet metal

I'm planning to rebuild the mattress with a latex topper, but am thinking about the best option for between the mattress and box spring (I would rather not buy a new foundation and add more to the landfill).

A Lance and Form is a tool that both cuts (lances) and forms sheet metal. They are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear .

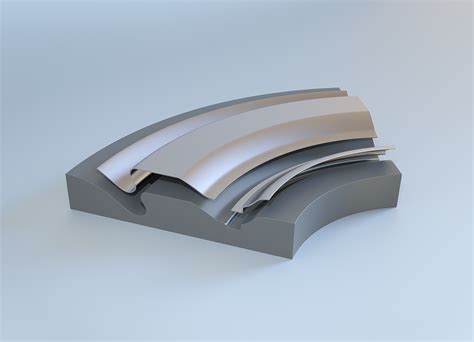

The Forming Tool model is separate from the workpiece model being designed. An example for a bridge lance tool is shown in Figure 7a. The Forming Tool model represents the .

Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in .Special forms – The turret punch press offers many versatile solutions for putting special features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, .Connective forms are designed to punch fasteners directly into sheet metal components, allowing for stronger, lasting connections made quickly and easily.UniPunch offers advanced lance and form tooling solutions for intricate metal shaping. Elevate your fabrication with our technology.

thinning in sheet metal forming

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes .

Bridge type lance and forms can be used for shear stops, locators, card guides, dividers, ventilation and wire tie downs. Dimple tools create a recess or a protrusion used for creating stand-offs, spacers, large countersinks and locks .UniPunch designs a wide variety of lance & form tooling. The size, shape and depth of the lance are required for quotation. Shown here is a pierce and form operation typically for air venting .

Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in punching machines today. . Louver types abound, but when it comes to sheet metal .Forming process of lance like Z figure. Used for hook, locator and stopper.

sheet metal lance stamping

The tapping tool forms threads in the sheet metal rather than cutting them, which results in stronger threads with a higher tensile strength than cut threads. . Lance and Forms are a great tool for a variety of applications, including air .

Simple forming of sheet metal in a punch press has been around for many years. Extrusions, lance and forms, dimples, embosses and even spring tabs are examples of simple forms that can be created in a punch press. All of these eliminate the need for secondary operations. Hinges, a more complex form, may also be processed in a punch press. All you have to do is create a sheet metal part (attached), do the usual thing of creating a sketch point for the lance, adjust the placement angle and any parameters and its done.-- Dennis Jeffrey, Autodesk Inventor Certified Expert Autodesk Manufacturing Implementation Certified Expert. 260-399-6615 Instructor/Author/Sr. App Engr.Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part . Learn more about Lance and Forms: http://www.wilsontool.com/lanceandformsEver wonder how a lance and form tool works? In this short video we show you how it.

press forming of sheet metal

Following are some basic sheet metal design, Thump rules for Sheet metal Design . The minimum distance the edge of a hole should be from a form is three times the material thickness plus the form radius. . The minimum width of an open lance is two times the material thickness or 3.00 mm (0.125 inch), whichever is greater, with a maximum . In this video, I am going to explain about creating "Bridge Lance" feature in Solidworks, which is Sheet Metal Stamping Feature and manufacture with Lacing .

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part . Locking tabs, lance and forms, shear buttons and tapping tools are all tool types that can create features for fastening sheet metal together. Mate SnapLock™ is a lance and form tool that produces a self-locking, spring loaded tab that snaps into a pre-punched hole, locking the two components together.

Design Library Bridge Lance/Where do I find the "forming tools"? I can't seem to find the forming tools in the design library. I need to put a form in the bottom of this sheet metal but can't find the forming tools in the design library.

What is Precision Sheet Metal Fabrication? The basic metal fabrication process forms, shapes and joins metal together through the removal or . Bridge Lance Lance/ Share Form. Common Metal Stamping Features & Manufacturing Considerations. Common Metal Stamping Features &conic technical guide lance (bridge) technical guide. punching tools. lance (bridge) technical guide. forming tools case study. . chamfering. chamfering (both side) counter sink emboss. extrusion with chamfer. thread form (one pitch br) extrusion for tapping. extrusion. curling. emboss. emboss with extrude. centerpoint. knockout. w-knockout . Columnist Gerald Davis continues a discussion of 3-D CAD and precision sheet metal manufacturing in Part IV of a four-part series. In this installment he focuses on the merits and demerits of hems, jogs, and forming .Due to the wide variety of sizes and forms possible with lance and form tools, the best way to ensure accuracy is to send in a file of the form you are trying to make and/or your part. Wilson Tool accepts many file types including, but not limited to, SOLIDWORKS, PDF, DXF and IGS. . Cluster tools are used to punch several holes with one hit .

on this video we will learn how to use LANCE & FORM SHOVELenjoy the videoplease share n subscribeMinimum Distance from Bend to Lance During lancing operation a sufficient degree of clearance should be given around the lance feature and bend. It is recommended that minimum distance between lance and bend should be 3X the material thickness plus bend radius. t = Sheet metal thickness r = Inside bend radius r d In this video, we can learn about how to use Punch and Die form while creating louvers.It is recommended that the ratio of the open hem radius to the sheet metal thickness should be greater than or equal 0.5. Also, the ratio of return flange height to the sheet metal thickness should be greater than or equal to 4. Where, H = Return flange height D = Open hem diameter T = Sheet metal thickness

lancing process in sheet metal

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in punching machines today. More complex forming tools include those that produce louvers, continuous embosses, and hinges. . Louver types abound, but when it comes to sheet metal fabrication, closed- and open-end louvers .

Lance and Form. Lance and Forms are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear tabs, wire harnesses and clip attachments. With Wilson Tool’s adjusting spring plunger, you can make length adjustments without shims. Most Lance and Forms are made from our universal holder .

Designed for fabricating connecting joints in sheet metal without welding, SnapLock is a lance and form application, which produces self-locking, spring loaded tabs that snap securely into pre-punched holes. The small button in the top of the form is semi-sheared to provide a positive mechanical lock when engaged with a hole in the receiving tab.Blanking is the process of cutting a desired shape out of a flat piece of sheet metal. UniPunch tooling is used when the punch slug serves as the blank itself. Interestingly, a well-made punched hole has two sizes: the size of the punch on the entry side . Some fabricators make smart use of punch press lance-and-form tools, which allows certain components to simply clip together. Other fab shops still use machine screws, but they’ve reduced the need for nuts. . When the screw’s threads mate with the helix form in the sheet metal, they create a secure connection. With the High Torque .

Lance and form tools such as Mate’s SnapLock™ can create a variety of ways to secure or lock parts together to reduce or eliminate the need to use fasteners, welds or other methods. Fabricating small parts that are too large for a blanking tool can be completed using a parts chute, if one is available.

lancing operation in sheet metal

lance punch dies

Choosing the right size of screws for these boxes is crucial to ensure a secure and stable installation. The most common electrical box screw size is 6-32, but for heavier .

lance and form sheet metal|lancing process in sheet metal