how far must bridge cranes be from electrical boxes Does anyone know how I can come up with load requirements for Cranes with the following sizes: 10ton, 20ton, 50ton, and 80ton. I'm working on a budget so it doesn't need to be exact.just in the ballpark. Get precision-engineered Aluminum CNC Turning Parts for your industrial needs. Our products are durable, reliable, and custom-made to fulfill the customer's requirements. Purchase now!

0 · overhead cranes requirements

1 · osha crane circuit breaker requirements

2 · floor operated cranes requirements

3 · electric bridge crane power requirements

4 · crane clearance requirements

5 · crane bridge brake requirements

6 · cabin operated cranes requirements

7 · bridge crane max amps

Shop online for wholesale cnc machine part? Global Sources has a full-scale list of wholesale cnc machine part products at factory prices featured by verified wholesalers & manufacturers from China, India, Korea, and other countries to satisfy all the requirements!

Does anyone know how I can come up with load requirements for Cranes with the following sizes: 10ton, 20ton, 50ton, and 80ton. I'm working on a budget so it doesn't need to be exact.just in the ballpark. Several factors come into play when determining the appropriate distance between bridge cranes and electrical boxes. The specific requirements may vary depending on the type . The installation of electrical equipment for bridge cranes and the laying of wires should be strictly carried out in accordance with the attached electrical schematic, wiring .Brakes for stopping the motion of the trolley or bridge shall be of sufficient size to stop the trolley or bridge within a distance in feet equal to 10 percent of full load speed in feet per minute when .

Explore our comprehensive Bridge Crane Installation Guide, covering crucial measurements, key parameters, and tips for selecting the right manufacturer. Ensure a successful, safe, and efficient crane system for your .

From the humble overhead crane to the mighty gantry and jib crane, we’ll investigate the uses of each type of bridge crane, as well as examine their unique features and distinctions from similar crane types.Learn the essential steps for installing a European Type Bridge Crane, including safety precautions, track laying, electrical setup, and final testing. Follow this comprehensive guide to ensure a smooth and safe crane installation process.

Cable festoons, conductor bars, or cable reels are used to transfer power from the building supply to the crane runway and bridge crane control panel. The same components are then used to supply power across the . New building, new 480 volt bridge crane. The crane gets its power from insulated tracks that run the length of the rail. I ran my THHN into a 4 square with enough wire length to .

overhead cranes requirements

One option is to determine 10% of the distance in feet. Put a full load on your crane and traverse the bridge or trolley at full speed for one minute. Mark the distance. Most trolleys will run out of room long before one minute .crane bridge. The crane bridge is connected to a number of crane trucks at each end depending on the capacity and span. The crane trucks can have 2, 4 or 8 wheels based on the capacity of the crane. The wheels ride along a crane rail which is supported by runway beams. The figure below illustrates the basic crane components; 1. Most of them, the bearing box just slides onto the axle. Wheels Do have a taper tread, about 1/2 inch over 5 inches between rims. You're right, it is to make them celf correcting in travel. That's on a crane with line shaft from gear reduction to both wheels on one girder. Individual drive, 4 gear boxes, for instance, use flat tread. Festooning .

Examples in this admittedly large category of overhead cranes include jib cranes (floor or wall attached cranes), gantry cranes (freestanding cranes supported by a supporting frame), workstation cranes (wide-spanning cranes featuring floor-mounted supports), and monorail cranes (cranes where the hook travels on a monorail-like track). One final .

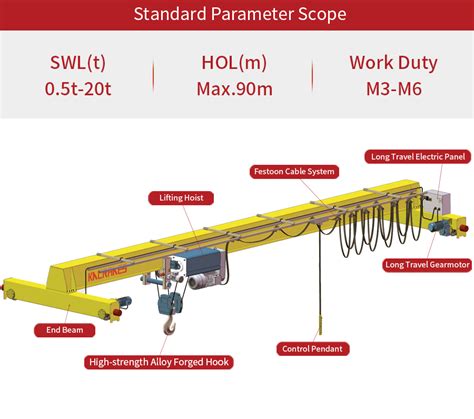

Purchasing a bridge crane can be a significant investment, and it is crucial to ensure that the crane system you choose is suitable for your specific needs. Before buying a bridge crane, you need to know several parameters or provide them to the manufacturer to design a crane solution tailored to your requirements. This comprehensive guide will .

Bridge crane operation involves various methods depending on the type of bridge crane and its specific application. As a core piece of equipment in construction and engineering, the operation methods of cranes play a crucial role in project efficiency and safety. . particularly in situations requiring complex electrical control. Common main .OSHA 1910.179 Overhead & Gantry Cranes Regulations The following excerpt is taken directly from OSHA 1910.179* Electrical Equipment. Wiring and equipment shall comply with subpart S of this part.Electrical crane controls Sidebar navigation (Main) Crane Guards for Electrical Equipment . As far as practical, the movement of each controller handle shall be in the same general directions as the resultant movements of the load. . The control for the bridge and trolley travel shall be so located that the operator can readily face the .Non-cab operated category 3-bridge crane. . Regardless of the method of communication used all crane signals must be _____. clear. Synthetic web slings should NOT be used in areas where temperatures exceed 194 degrees Fahrenheit. True. If an object is 6 feet long, 5 feet wide, and 4 feet high, what is the volume of the object? .

Capacities: 250 to 4,000 lbs. Bridge Lengths, overall: up to 40’ Runway Spans: up to 40’ Height — Floor-to-Trolley Clevis: determined by ceiling structure Ceiling-mounted bridge cranes are great for applications with limited floorspace, facilities with large mobile equipment, and facility layouts that might change in the future. Ceiling-mounted systems also allow you to readily. load limiter as a mechanical failure detector The team of technicians from the electrical sector is asked to come to observe and diagnose a bridge crane failure. A team is having trouble with this .product. All Gorbel® cranes are pre-engineered for powered hoist operation. The hoist weight allowance is 15% of the crane capacity (for example, a crane rated for 1000 pounds, allows for a 1000-pound live load plus 150 pounds for the weight of the hoist). There is also an allowance of 25% of the crane capacity for impact caused by hoist use.MECHANICAL AND ELECTRICAL SAFETY FEATURES Bradford P. Lytle, P. E.; Overhead Bridge Crane Specialist Chairman, ASME Committee on Cranes for Nuclear Facilities NASA, Kennedy Space Center Thomas A. Walczak, P. E. Critical Control System Consultant Sugar Land, Texas Abstract The use of overhead traveling bridge cranes in many varied applications .

Ensure that whenever cranes must repeatedly travel beneath power ines, a route is plainly marked and “rider poles” are erected on each side of the crossing approach to ensure that the crane structure is lowered to a safe height. (Figures 1 and 5 are redrawn from Mobile Crane Manual with permission from Construction Safety Association of . Used to electrify and power overhead crane, monorail, and hoist systems along the runway to power the bridge, or along the bridge to power the trolley, conductor bar systems are typically guarded or isolated with a cover or insulation. . This guarding eliminates the risk of an electrical shock should personnel or another component of an . Wheel load refers to the weight that each wheel on the crane must support, including the weight of the crane itself, any additional loads, and the weight of the supporting structure. Calculating bridge crane wheel loads is crucial because overloading a crane can lead to damage to crane components and even accidents that endanger personnel and .How Heavy Is A 16 Ton Overhead Crane? How Heavy Is A Crane Hoist? The crane weights exactly 11830kgs in total. This is made from 8776kgs for the main beams, 1336kgs for the Demag hoist unit, 1606kgs for the end carriages .

Application. This section applies to overhead and gantry cranes, including semigantry, cantilever gantry, wall cranes, storage bridge cranes, and others having the same fundamental characteristics. These cranes are grouped because they all have trolleys and similar travel characteristics. 1910.179(b)(2) New and existing equipment.

We have two separate cranes in separate bays being fed from 480 volt switchgear located in an electric room. We showed a 2000 amp and 1600 amp disconnect located in each bay in line of sight from the cranes. Article 610.31 of the NEC states as follows: 610.31 Runway Conductor Disconnecting.

Install the bridge crane by inserting both end trucks into one end of the runway tracks. Adjust and tighten the bridge end truck set screws to provide a minimum clearance of 2” between the ends of the bridge and any side obstructions. Adjust support brackets or hangers to provide a minimum clearance of 3” between the top of the bridge and any In the construction of power plants, overhead cranes are a widely used lifting equipment. Its frequent use, large workload, vibration, and thus a high failure rate, bringing many adverse effects to the construction. Bridge crane electrical system and the commissioning process, scientific and reasonable construction methods are the key to ensure the quality of . A simple post and swing-arm crane, with a hydraulic ram to raise and lower the arm would avoid the uncontrolled deployment issue and allow the unit to be mounted on a substantial flange bolted to the the floor, perhaps with a brace to the box corner post, where the leverage exerted would be much reduced, along with the chance of damage to .

As a result, when the millwright places the lock on the lever in the "off" position, the stub located inside the electrical box remains in the "on" position. The employee does not attempt to verify deenergization by using the crane start button. When he contacts the energized electrical bus bar located near the bridge railings, fatal injury . Selection of gantry cranes above 15 tons requires consideration of most bridge crane factors. In the smaller sizes, where the overwhelming number are found, several other points enter the equation, including aluminum or steel construction, adjustable or fixed height, span, type of casters, and height from floor to I-beam.

On cab-operated cranes with cab on bridge, a bridge brake is required as specified under paragraph (f)(4) of this section. On cab-operated cranes with cab on trolley, a bridge brake of the holding type shall be required. On all floor, remote and pulpit-operated crane bridge drives, a brake of noncoasting mechanical drive shall be provided.Overhead crane power supply, electrical system, electrical equipment installation & wire laying are the key to ensure overhead eot crane system quality. WhatsApp:+ 86 15138711597 [email protected] HomeApplied Grounding and Bonding—2020 Textbook (Chapter 15) National Electrical Code—2020 Learn with flashcards, games, and more — for free. No.730, Xinghai Center, Hongqi District,Xinxiang,Henan,China. Weiqi Road, Crane IndusPark, Changyuan County ,Henan Province, China. 0086-373-3809941

cheap copper sheet metal

cheap cnc machine reddit

Notable copper alloys encompass brass (copper and zinc), bronze (copper and tin), and cupronickel (copper and nickel), each tailored for distinct applications. Our company excels in the precision processing of copper parts, with a primary focus on .

how far must bridge cranes be from electrical boxes|electric bridge crane power requirements