electrical enclosure layouts Electrical enclosure design includes all the steps involved in creating housing for electrical components. This includes everything from choosing the right material to fabricating the enclosure itself. TICONN Waterproof Electrical Junction Box IP67 ABS Plastic Enclosure with Hinged Cover with Mounting Plate, Wall Brackets, Cable Glands (Clear, 8.7"x6.7"x4.3")

0 · thermal insulation for electrical enclosures

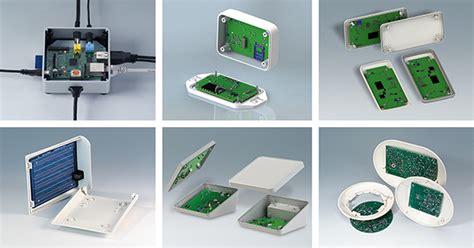

1 · pcb enclosure design guidelines

2 · inside of industrial electrical cabinet

3 · enclosure design of electronics equipment

4 · electronic enclosure design guidelines

5 · electrical enclosure types

6 · different types of wiring enclosures

7 · different types of electrical enclosures

Junction Box, IP67 Waterproof Plastic Enclosure for Electrical Project, Hinged Grey Cover, Includes Mounting Plate and Wall Bracket 290×190×140mm (11.4"×7.5"×5.5")

These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access .

Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating .

thermal insulation for electrical enclosures

pcb enclosure design guidelines

Electrical enclosure design includes all the steps involved in creating housing for electrical components. This includes everything from choosing the right material to fabricating the enclosure itself.These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access the devices to control and operate machinery and systems. Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs .Protocase Designer ® is a free downloadable 3D CAD package that allows you to design electronic enclosures from templates. It is the fastest way to design custom enclosures and requires no prior CAD experience.

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards. Control panel layout design is something of an art form. The goal is to logically arrange each element in a way that balances performance, safety, and usability. One small change to appease the safety gods can upset wire arrangements or current flow.Electrical enclosures are the cornerstone of electrical infrastructure, housing electrical components, assemblies, and circuitry. These fortified structures are pivotal in isolating sensitive electronic equipment from external environmental influences, including dust, water ingress, and chemical corrosion. Today’s post offers a comprehensive guide to electrical enclosures, including the various types, the significance of enclosure ratings and construction materials, and how to choose the proper electrical cabinets or enclosures for different industrial applications.

Engineers can easily layout components inside panel enclosures in 3D and 2D at a 1:1 scale with automatic design rule checks. E3.panel has dynamic integration with E3.schematic and E3.cable modules. Users can effortlessly navigate between the . These documents help to create a panel layout drawing’s needed enclosure size. The layout should follow best practices by separating high-power and low-power components and the related electrical noise, along with grouping like components together and maintaining proper spacing between components for proper heat distribution. Electrical enclosure design includes all the steps involved in creating housing for electrical components. This includes everything from choosing the right material to fabricating the enclosure itself.

These enclosures house electrical and electronic controls and/or instruments and typically have HMIs, pushbuttons, switches and other pilot devices and controls where operators can access the devices to control and operate machinery and systems. Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs .Protocase Designer ® is a free downloadable 3D CAD package that allows you to design electronic enclosures from templates. It is the fastest way to design custom enclosures and requires no prior CAD experience.

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards. Control panel layout design is something of an art form. The goal is to logically arrange each element in a way that balances performance, safety, and usability. One small change to appease the safety gods can upset wire arrangements or current flow.Electrical enclosures are the cornerstone of electrical infrastructure, housing electrical components, assemblies, and circuitry. These fortified structures are pivotal in isolating sensitive electronic equipment from external environmental influences, including dust, water ingress, and chemical corrosion. Today’s post offers a comprehensive guide to electrical enclosures, including the various types, the significance of enclosure ratings and construction materials, and how to choose the proper electrical cabinets or enclosures for different industrial applications.

inside of industrial electrical cabinet

Engineers can easily layout components inside panel enclosures in 3D and 2D at a 1:1 scale with automatic design rule checks. E3.panel has dynamic integration with E3.schematic and E3.cable modules. Users can effortlessly navigate between the .

enclosure design of electronics equipment

electronic enclosure design guidelines

electrical enclosure types

different types of wiring enclosures

IP68 Waterproof Junction Box Outdoor, 4 Way Underground Electrical Junction Box, Plastic Electrical Box with Terminal Block, Suitable for LED Landscape Lighting, Garden Lights, Solar Power and More

electrical enclosure layouts|different types of wiring enclosures