cnc machine working wikipedia Many other tools have CNC variants, including:• 3D printing• See more Uline stocks over 42,000 shipping boxes, packing materials, warehouse supplies, material handling and more. Same day shipping for cardboard boxes, plastic bags, janitorial, retail and shipping supplies.

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

Apa Itu Yellow Box Junction? Yellow Box Junction adalah sebuah marka jalan yang biasanya berbentuk kotak berwarna kuning dan ditempatkan di persimpangan jalan. Marka ini terdiri dari garis-garis kuning yang membentuk .

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into . See moreMotion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more

can vectric aspire run cnc machine

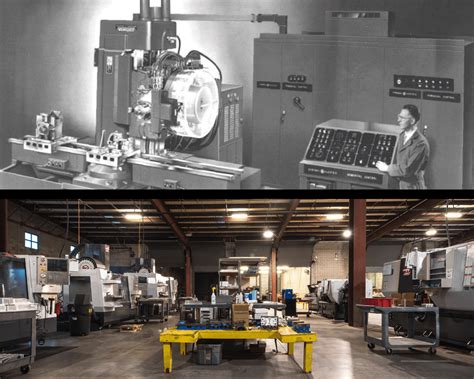

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See moreMany other tools have CNC variants, including:• 3D printing• See moreWithin the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See more

Now the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See more

can you modge podge fabric to metal

In CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See moreIn numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See moreA computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .

can weatherproof electrical boxes be buried

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.. Motorized linear slides such as machine slides, X-Y tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball . CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .

Working Principle of CNC Machine. Fig 2: Working Principle of CNC machine. The process of CNC machining involves several integral components working seamlessly in tandem. Initially, the part program is input .

CNC machine pouring coolant to keep the tool and parts from getting hot Lathe machine. Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, [1] which utilizes machine tools, in contrast .

A coordinate-measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, the most common being mechanical and laser sensors, though optical and white light sensors do exist.A punching machine is a machine tool for punching and embossing flat sheet-materials to produce form-features needed as mechanical element and/or to extend static stability of a sheet section. According to the file, Richard Walsh, the county of Grayson, and the State of Texas had invented and applied for US patent in 1894. . CNC punching. A .

who invented the cnc machine

when were cnc machines invented

Diamond flycutting. Diamond turning is turning using a cutting tool with a diamond tip. It is a process of mechanical machining of precision elements using lathes or derivative machine tools (e.g., turn-mills, rotary transfers) equipped with natural or synthetic diamond-tipped tool bits.The term single-point diamond turning (SPDT) is sometimes applied, although as with other lathe . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and .

This page was last edited on 19 February 2009, at 14:00 (UTC).; Text is available under the

computer numerically controlled machines

CNC riveting is a CNC process used for obtaining permanent mechanical fastening of geometrical shapes, ranging from simple to complex shapes, such as aircraft fuselages. This is done in a shorter duration of time with a high riveting rate. The process is fast, robust, and is flexible in nature; thus improving its usage and providing reliability to the riveted joint along with the final .Diagram of a laser cutter Laser cutting process on a sheet of steel CAD (top) and stainless steel laser-cut part (bottom). Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists.Operator Training and Safety for CNC Machines. Alright, let’s talk safety first. When you’re working with CNC machines, safety always comes first. Make sure you’re wearing the proper protective gear, like safety glasses and gloves, and follow all safety protocols and guidelines. Remember, your safety is non-negotiable! Now, let’s talk .

CNC plasma cutting Plasma cutting performed by an industrial robot. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.Plasma cutting is often used .

How Does a CNC Machine Work? Using a CNC machine is a simple process explained below: Design: In this process, an individual uses specialized computer applications to create a detailed design or blueprint for the part to be produced. This design can be developed through drawings, . 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command .

A list of the work materials is required for the assignment of cutting conditions. Different qualities and additional terms for the materials are contained in the list, and extended by the individual designations as used by the respective enterprise. . Modern CNC-Machines (i.e. Mill-Turn-Machines) are highly productive, however they demand .Lights-out manufacturing is the methodology of fully automating the production of goods at factories and other industrial facilities, such as to require no human presence on-site. Many of these factories are considered to be able to run "with the lights off," but few run exclusively lights-out production. For example, in computer numerical control machining, the presence of human .Chrome-cobalt disc with crowns for dental implants, manufactured using WorkNC CAM. Traditionally, CAM has been numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in CAD.As with other "computer-aided" technologies, CAM does not eliminate the need for skilled professionals .

A machine tool is a machine that cuts, shapes, or forms material. [1] A machine tool has three basic elements: A work-holding device for holding the material, or workpiece. A tool-holding device for holding the tool. A method for guiding the movement of the tool relevant to the workpiece or material. A CNC lathe designed for cutting wood

The figure shows the CNC machine working: First, the part program is entered into the MCU of the CNC. The MCU processes all the data and according to the program prepared, it prepares all the motion commands and gives them to the driving system. The drive system acts as motion commands sent by the MCU. The drive system manages the motion and .Siemens CNC panel. The automation of machine tool control began in the 19th century with cams that "played" a machine tool in the way that cams had long been playing musical boxes or operating elaborate cuckoo clocks. Thomas Blanchard built his gun-copying lathes (1820s–30s), and the work of people such as Christopher Miner Spencer developed the turret lathe into the .Center lathe with digital read out and chuck guard. Size is 460 mm diameter x 1000 mm between centers. In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, .

A metal lathe is an example of a machine tool.. A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations.Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided .CNC plate roll machine. A plate rolling machine is a machine that will roll different kinds of sheet metal into a round or conical shape. It can be also called a “roll bending machine”, “plate bending machine” or “rolling machine”. There are different kinds of technology to roll the metal plate:Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may want to mount a spur drive or work in a collet.Another example is a drill press, to which an operator may want to mount a bit directly, or using a drill chuck.. Virtually all milling machines, from the oldest manual machines .

Titanium drilling. Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point.The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute.This forces the cutting edge against the work-piece, cutting off chips (swarf .

can you box in electric meter

आज हम सीखेंगे कि CNC मशीन क्या है? - CNC Machine in Hindi, और इस पर कैसे काम करते हैं। जैसा कि सभी जानते हैं कि आज के ज़माने में भाग दौड़ भरी ज़िन्दगी है, और सभी

can you attach a metal carport to your house

Anmei U Shaped Connector Bracket, 5 Hole U Shaped Strut Connector Bracket, Height 1-3/4", Width 1-1/2", Thickness 5mm, Fit for 1/2" Bolt in 1-5/8" Strut Channel

cnc machine working wikipedia|cnc machine acronym